Introduction to Wind turbine bearing forgings, forging specifications, model parameters

Wind turbine bearing forgingsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a common Wind turbine bearing forgings。The following is to introduce the Wind turbine bearing forgings:

1、Brief introduction of Wind turbine bearing forgings

Wind turbine bearing forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine bearing forgings.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,it is an ideal choice for customers to buy Wind turbine bearing forgings。

Wind turbine bearing forgings

2、Wind turbine bearing forgings characteristics

Wind turbine bearing forgingsLight weight,High productivity,high-precision,Good anti-fatigue performance,High production efficiency,is a popular Wind turbine bearing forgings,usually used in war industry, construction machinery, rail traffic, power, energy and other fields,refers to the workpiece or blank obtained by forging metal blank.,is a Wind turbine bearing forgings。

Wind turbine bearing forgings

3、Wind turbine bearing forgings advantage

The advantages of Wind turbine bearing forgings are as follows:

- Good fatigue resistance.

- high-intensity

- high tenacity

- Reduce the amount of subsequent processing

- Replace other processing methods

The particle flow inside the Wind turbine bearing forgings flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The fiber structure of the Wind turbine bearing forgings is reasonably distributed, which improves the toughness of the material and enables the Wind turbine bearing forgings to bear greater impact force and alternating stress.

The forming precision of the Wind turbine bearing forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In some cases, Wind turbine bearing forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Wind turbine bearing forgings

4、Wind turbine bearing forgings video live broadcast

On-site aerial photography of Wind turbine bearing forgings。

Wind turbine bearing forgings

As you can see from the live video.,Jianing it has the characteristics of Great forging flexibility, Can bear large impact force or heavy load., High productivity, Good anti-fatigue performance and Great forging flexibility。

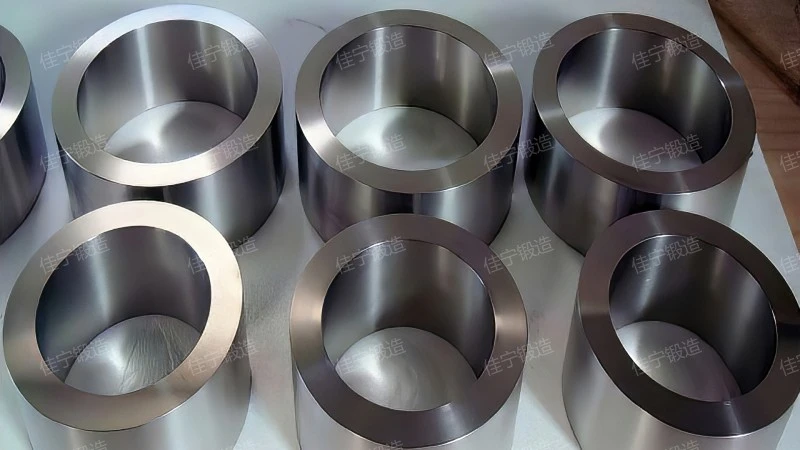

5、Wind turbine bearing forgings work site real shot

The styles and designs of Wind turbine bearing forgings are diverse, and the specifications and models can be tailored according to users' needs, providing high-definition drawings for our customers' reference.。

Wind turbine bearing forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、How much is the Wind turbine bearing forgings?

The Wind turbine bearing forgings price is introduced as follows:

- technology content

- product function

- sales mode

- regional advantages

- product configuration

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Wind turbine bearing forgings are closely related. Jianing has comprehensively measured the configuration and sales price of products when designing Wind turbine bearing forgings, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Wind turbine bearing forgings

Wind turbine bearing forgingsis a kind of high quality and low price Wind turbine bearing forgings,it is widely used in metallurgy, automobile, construction machinery, energy and power,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine bearing forgings can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine bearing forgings.。

Related recommendation

-

Introduction to Groove type welded flange ring, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Forged parts with irregular shafts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Grade IV pressure vessel forgings and forging working principle

2025-5-26 -

What is a Flat plate welded steel flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Drive shaft free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Groove flange, flange specifications, model parameters

2025-5-26 -

What is a Shaft forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

发电机法兰

2024-12-10 -

What is a Single blind flange? Introduction to the advantages and characteristics of blind plate functions

2025-5-26 -

Introduction to Porous blind plate and blind plate advantages and features

2025-5-26