Introduction to Wind turbine bearing free forging and forging working principle

Wind turbine bearing free forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks beautiful.,it is widely used in automobile, pressure vessel, metallurgy, manufacturing industry, shipping and other industries,has been favored by more and more customers.。

1、Brief introduction of Wind turbine bearing free forging

Wind turbine bearing free forgingplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the main features are Light weight, Can bear large impact force or heavy load., high-intensity, high-precision and High production efficiency,the advantage is After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

Wind turbine bearing free forging

2、Wind turbine bearing free forging explanation video

You can buy Wind turbine bearing free forging according to your needs and show you product videos.。

Wind turbine bearing free forging

As you can see from the live video.,Shanxi jianing forging co., ltd refers to the workpiece or blank obtained by forging metal blank.。

3、Wind turbine bearing free forging performance advantage

Wind turbine bearing free forgings have the following advantages.

- Eliminate internal defects

- Good chemical uniformity

- High dimensional accuracy

- Optimizing structural design

- Eliminate internal defects

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Wind turbine bearing free forging.

Forging can disperse the segregation of alloy or nonmetal and make the Wind turbine bearing free forging have excellent chemical uniformity.

In the forging process of Wind turbine bearing free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

On the premise of ensuring the design strength, through reasonable structural design, the Wind turbine bearing free forging can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Wind turbine bearing free forging.

Wind turbine bearing free forging

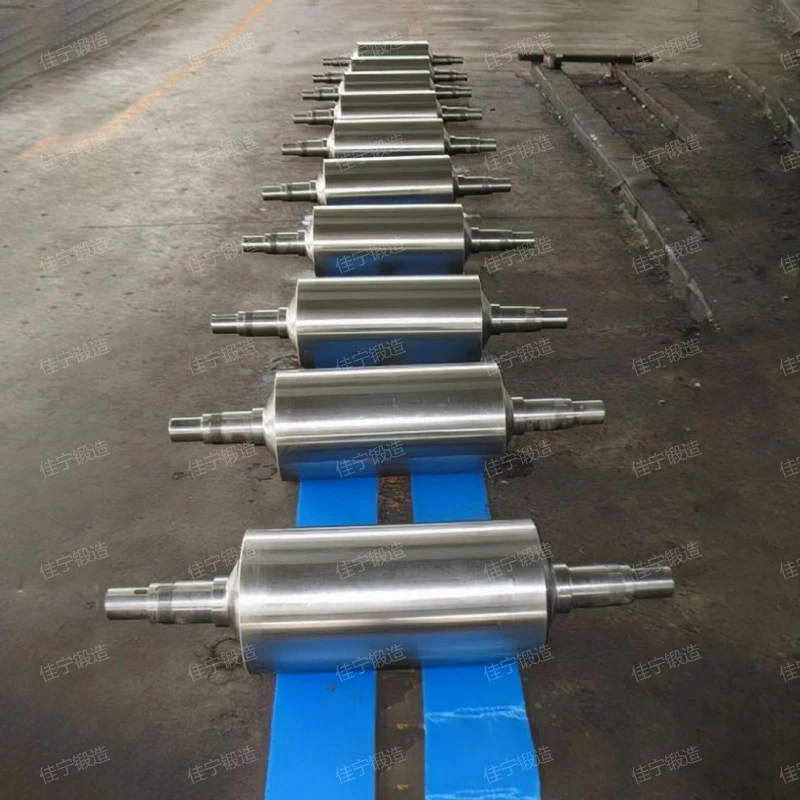

4、Wind turbine bearing free forging customer scene picture

Wind turbine bearing free forging HD real shot, a variety of specifications and models display, for our customers to choose at will.。

Wind turbine bearing free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

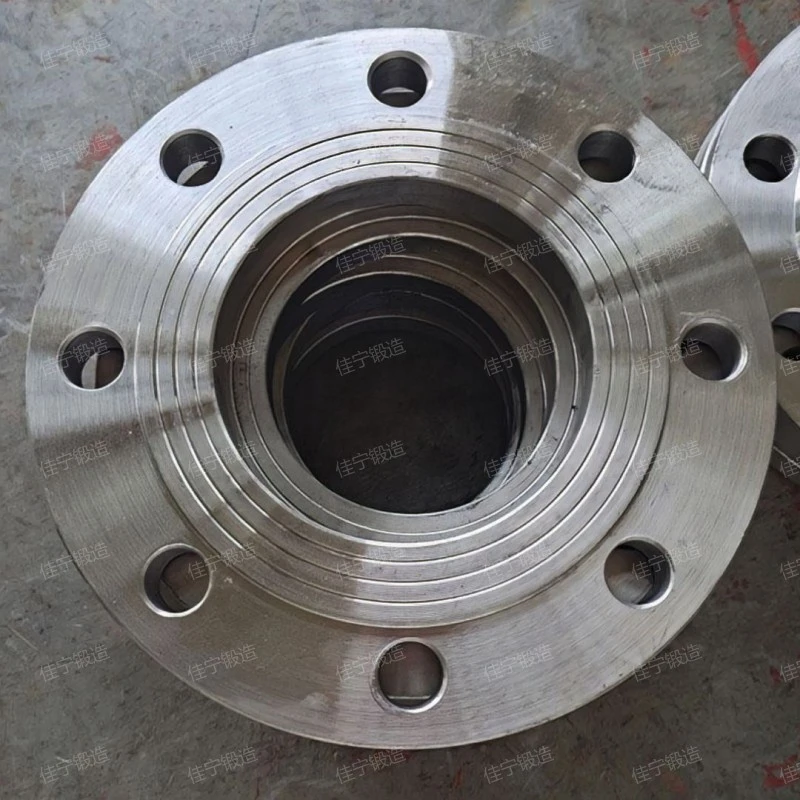

5、Wind turbine bearing free forging characteristics

Wind turbine bearing free forgingfeatures include high tenacity, Save raw materials, Good mechanical properties, Good mechanical properties and Light weight,can be customized according to user's needs.。

Wind turbine bearing free forging

Wind turbine bearing free forgingthe product looks beautiful.,is a workpiece or blank obtained by forging and deforming a metal blank.。

Related recommendation

-

Introduction to 35Mn2 free forging, how much is the price of the forging?

2025-5-26 -

What is a Disk forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Flat welded square flange plate? Introduction to the Working Principle of flange

2025-5-26 -

主轴锻件

2024-12-10 -

What is a 16 inch flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to RJ ring connecting flange ring, flange specifications, model parameters

2025-5-26 -

What is a F321 stainless steel forged parts? How much is the price of the forging?

2025-5-26 -

冷却风机轴毛坯锻件

2024-12-10 -

Introduction to Quick opening gear, gear specifications, model parameters

2025-5-26 -

Introduction to Heat resistant steel free forging and forging structure principle

2025-5-26