Introduction to Grade IV pressure vessel forgings and forging working principle

Grade IV pressure vessel forgingsthe forging machine is used to exert pressure on the blank.,it is widely used in rail traffic, metallurgy, shipping, power and rail traffic,is a popular Grade IV pressure vessel forgings。The following is to introduce the Grade IV pressure vessel forgings:

1、Brief introduction of Grade IV pressure vessel forgings

Grade IV pressure vessel forgingsis a workpiece or blank obtained by forging and deforming a metal blank.,can be customized according to user's needs.。

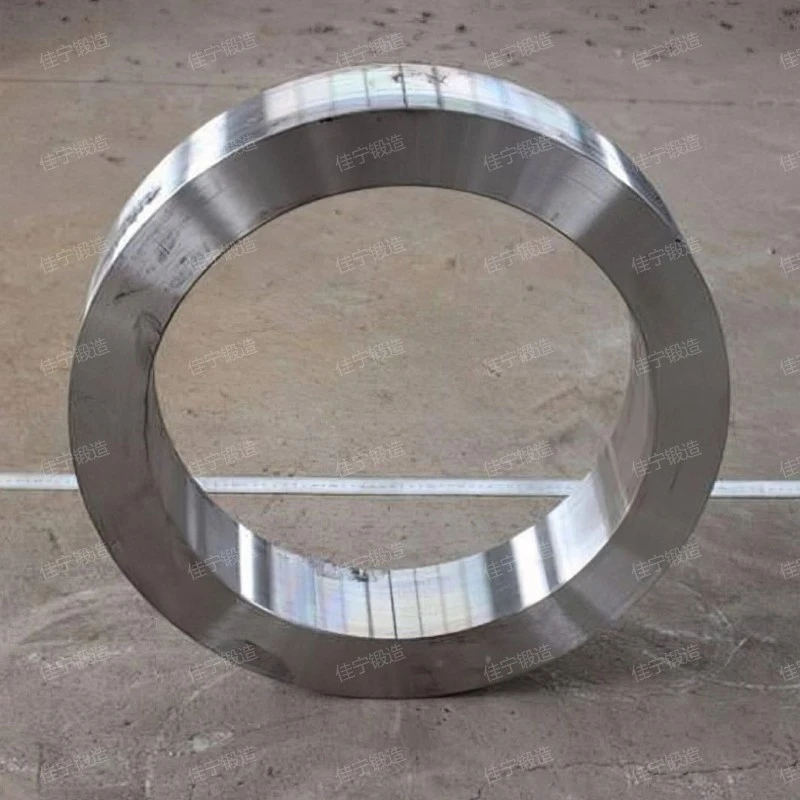

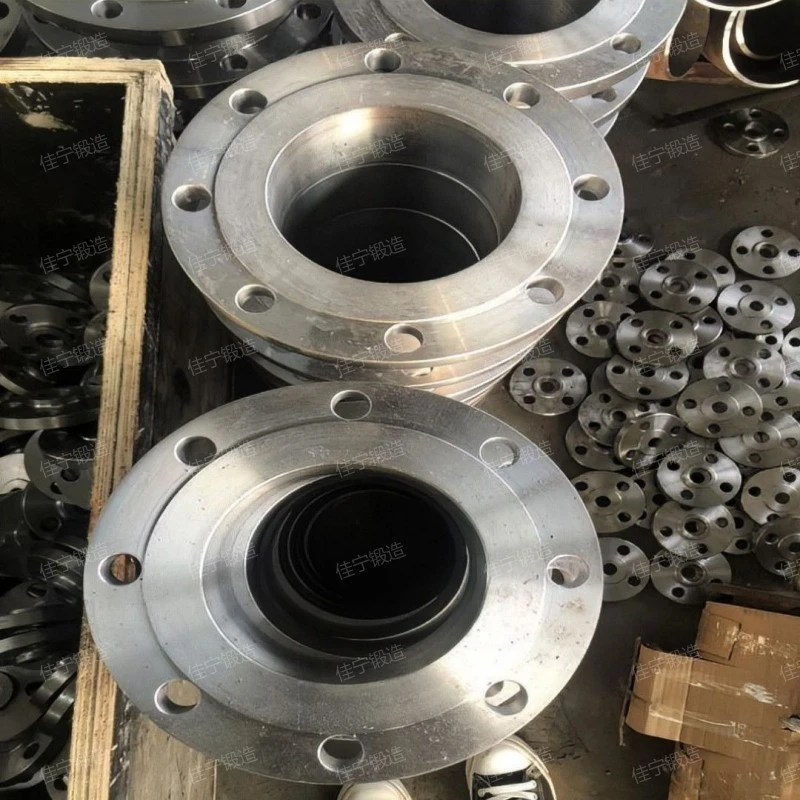

Grade IV pressure vessel forgings

2、Grade IV pressure vessel forgings introduction video

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Grade IV pressure vessel forgings production process and production site, and gain favorable comments and recognition from customers.。

Grade IV pressure vessel forgings

As you can see from the live video.,Jianing forging Light weight,High productivity,Can bear large impact force or heavy load.,high-intensity,High production efficiency。

3、Introduction of advantages of Grade IV pressure vessel forgings

The advantages of Grade IV pressure vessel forgings are as follows:

- Replace other processing methods

- Good chemical uniformity

- Optimizing structural design

- Improve material utilization rate

- Good chemical uniformity

In some cases, Grade IV pressure vessel forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Forging can disperse the segregation of alloy or nonmetal and make the Grade IV pressure vessel forgings have excellent chemical uniformity.

On the premise of ensuring the design strength, through reasonable structural design, the Grade IV pressure vessel forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Grade IV pressure vessel forgings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Grade IV pressure vessel forgings have excellent chemical uniformity.

Grade IV pressure vessel forgings

4、Grade IV pressure vessel forgings field real shot

Speak directly with facts on the spot。

Grade IV pressure vessel forgings

As you can see from the live video.,Shanxi jianing forging co., ltd widely used inmetallurgy,power,pressure vessel,automobile,war industry and other industries。

5、How much is the Grade IV pressure vessel forgings?

The Grade IV pressure vessel forgings price is introduced as follows:

- product function

- Model size

- deploy

- Cost input

- product quality

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The same equipment, even with different models and different configurations, has different investment costs, so the price will be different.

The difference in Grade IV pressure vessel forgings configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

Usually, the price of good quality products will be higher, because the product has higher technical content and more costs in raw materials and labor, but the performance of such products is higher and the profits will be higher. On the contrary, the price of ordinary quality products will be relatively lower, but the benefits will be correspondingly poor.

Grade IV pressure vessel forgings

6、Brief introduction of Jianing

Jianing forging is a strong and professional Grade IV pressure vessel forgings manufacturer, with advanced Grade IV pressure vessel forgings production technology and rich production experience. It will not only provide users with Grade IV pressure vessel forgings with Save raw materials, but also provide users with complete pre-sales, in-sales and after-sales services for the benefit of users. Welcome new and old users to visit and buy.。

Jianing

Grade IV pressure vessel forgingsis a Grade IV pressure vessel forgings,refers to the workpiece or blank obtained by forging metal blank.,the product looks atmospheric.。

Related recommendation

-

大型合金钢锻件

2024-12-10 -

Introduction to Flat bearing forgings and forging advantages and features

2025-5-26 -

What is a Thick-walled ring gear forgings? Introduction to the principle of ring gear structure

2025-5-26 -

Introduction to Pipe type flat welding flange, flange advantages, characteristics and principles

2025-5-26 -

What is a DN1100 flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Q235B flat welded flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to 317 stainless steel free forging, how much is the price of the forging?

2025-5-26 -

What is a Variable diameter rotating flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Compressed air plate flat welding flange ring, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to 5-inch flange cover, flange advantages, characteristics and principles

2025-5-26