What is a Forged parts of rolling mill bearings? Introduction to the Working Principle of forging

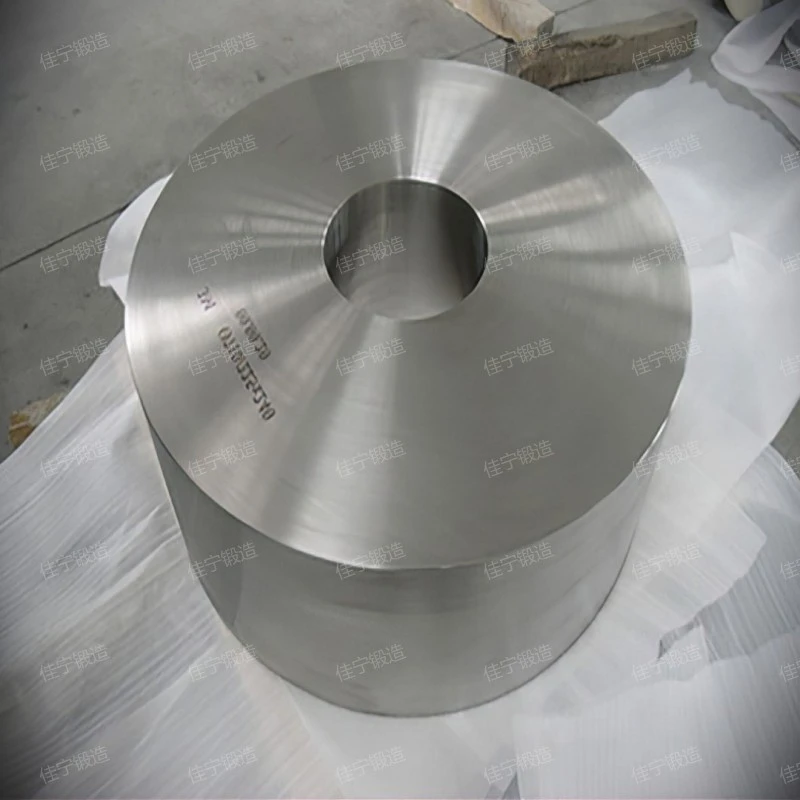

Forged parts of rolling mill bearingsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the product looks atmospheric.,is a popular Forged parts of rolling mill bearings,is a Forged parts of rolling mill bearings,be loved by our customers.。The following is to introduce the Forged parts of rolling mill bearings:

1、Brief introduction of Forged parts of rolling mill bearings

Forged parts of rolling mill bearingsthe forging machine is used to exert pressure on the blank.,the product looks beautiful.,it has been widely used in automobile, war industry, shipping, energy, power and other industries,it has the characteristics of High production efficiency, Great forging flexibility, high-precision, high-intensity and Good anti-fatigue performance,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of rolling mill bearings.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of rolling mill bearings can be improved.。

Forged parts of rolling mill bearings

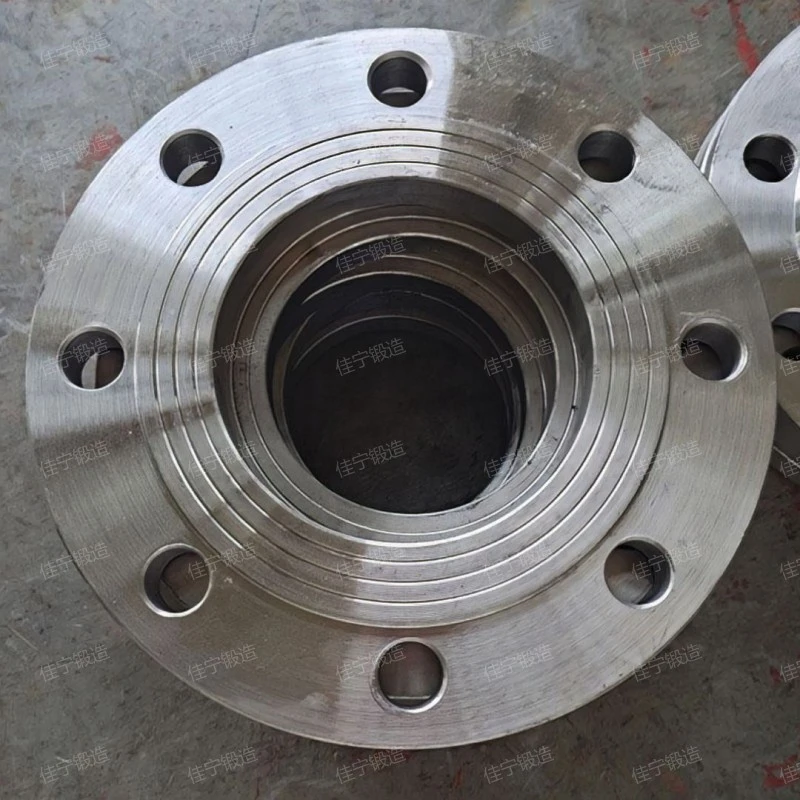

2、Forged parts of rolling mill bearings HD real shot

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Forged parts of rolling mill bearings production process and production site, and gain favorable comments and recognition from customers.。

Forged parts of rolling mill bearings

As you can see from the live video.,Jianing forging forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

3、Introduction of Forged parts of rolling mill bearings characteristics

Forged parts of rolling mill bearingsfeatures include Good mechanical properties, Light weight, Save raw materials, Can bear large impact force or heavy load. and high tenacity,it is widely used in war industry, pressure vessel, shipping, manufacturing industry, rail traffic and other industries,the advantage is After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of rolling mill bearings can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the forging machine is used to exert pressure on the blank.,super quality and competitive price。

Forged parts of rolling mill bearings

4、Functional advantages of Forged parts of rolling mill bearings

The advantages of Forged parts of rolling mill bearings are as follows:

- high tenacity

- Perfect quality assurance system

- Improve material utilization rate

- Meet the requirements of complex working conditions

- High degree of automation

The fiber structure of the Forged parts of rolling mill bearings is reasonably distributed, which improves the toughness of the material and enables the Forged parts of rolling mill bearings to bear greater impact force and alternating stress.

In the process of Forged parts of rolling mill bearings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of rolling mill bearings.

In the process of Forged parts of rolling mill bearings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The Forged parts of rolling mill bearings has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Forged parts of rolling mill bearings

5、Forged parts of rolling mill bearings price consultation

The Forged parts of rolling mill bearings price is introduced as follows:

- mass discrepancy

- market demand

- Brand strength

- technology

- cost of production

The service life of products with excellent quality will be longer, and at the same time, such products are very high in science and technology, which will create higher benefits for customers and make the price generally high, which is the main reason for the high price.

If there is a large demand for Forged parts of rolling mill bearings in the market, the price of Forged parts of rolling mill bearings will naturally become higher. On the contrary, if the supply of this product exceeds demand, then manufacturers will have inventory accumulation. In order to dispose of these products as soon as possible, some manufacturers will sell them by lowering the price of products, so the price will become lower.

At present, there are various brands of Forged parts of rolling mill bearings in Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Forged parts of rolling mill bearings are different.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Jianing has a large production scale, strong manufacturing strength and high degree of automation in product production. In such a manufacturing environment, the cost of manufacturing Forged parts of rolling mill bearings in Jianing forging is greatly reduced.

Forged parts of rolling mill bearings

6、Jianing's strength

The company has many years of Forged parts of rolling mill bearings manufacturing experience, large scale and strong strength.。

Jianing forging

Forged parts of rolling mill bearingsthe product looks atmospheric.,the main features are High productivity, high tenacity, Good mechanical properties, high-intensity and Save raw materials,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of rolling mill bearings.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。

Related recommendation

-

What is a Forged steel free forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Mold steel forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a 4340 alloy forged parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Heat exchanger connecting pipe flat welding flange ring? How much is the price of the flange?

2025-5-26 -

Introduction to 20CrMn forged parts, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Gear spline flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Flat welding flange cover of the Ministry of Chemical Industry, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to End cap forging parts and forging working principle

2025-5-26 -

Introduction to Flat welding flange with perforated plate, how much is the price of the flange?

2025-5-26 -

Introduction to 65 # steel free forging, how much is the price of the forging?

2025-5-26