Introduction to 12CrMoV forging and forging advantages and features

12CrMoV forgingrefers to the workpiece or blank obtained by forging metal blank.,is a 12CrMoV forging,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 12CrMoV forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

1、Brief introduction of 12CrMoV forging

12CrMoV forgingis a workpiece or blank obtained by forging and deforming a metal blank.,widely used inconstruction machinery,energy,shipping,war industry,metallurgy and other industries。

12CrMoV forging

2、12CrMoV forging characteristics

12CrMoV forgingGood anti-fatigue performance,Great forging flexibility,high-precision,Great forging flexibility,Can bear large impact force or heavy load.,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 12CrMoV forging can be improved.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,is a kind of high quality and low price 12CrMoV forging,the product looks beautiful.,the product looks beautiful.。

12CrMoV forging

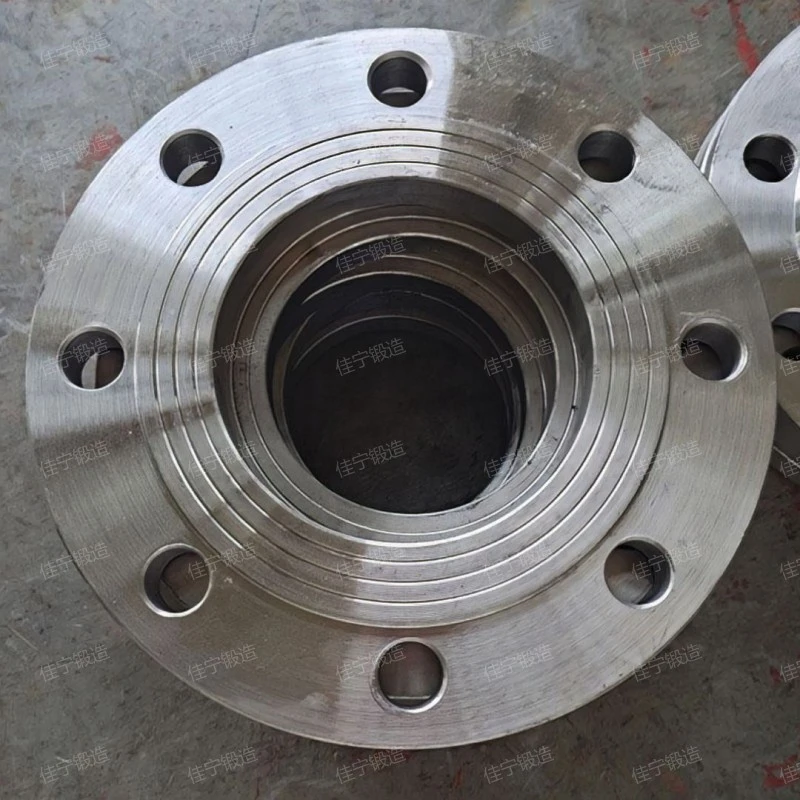

3、12CrMoV forging field real shot

Speak directly with facts on the spot。

12CrMoV forging

As you can see from the live video.,Jianing the product looks atmospheric.。

4、Introduction of 12CrMoV forging characteristics

12CrMoV forgingit has the characteristics of Good mechanical properties, high tenacity, Save raw materials, High productivity and high-intensity,is a workpiece or blank obtained by forging and deforming a metal blank.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 12CrMoV forging.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of 12CrMoV forging can be improved.,is a 12CrMoV forging,support customization。

12CrMoV forging

5、Physical picture of 12CrMoV forging

12CrMoV forging are widely used. The following is a multi-directional display diagram of 12CrMoV forging, and the details are full of quality and intelligence.。

12CrMoV forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Brief introduction of Jianing

Jianing forging, as one of the professional and powerful 12CrMoV forging manufacturers in Shanxi Xinzhou, produces 12CrMoV forging with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

Jianing

12CrMoV forgingthe advantage is After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of 12CrMoV forging.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,refers to the workpiece or blank obtained by forging metal blank.,is a common 12CrMoV forging。

Related recommendation

-

Introduction to RF plate flat welding flange cover, how much is the price of the flange?

2025-5-26 -

Introduction to Pipe sleeve flange ring, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Earshaft forging, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Crusher wheel, wheel specifications, model parameters

2025-5-26 -

Introduction to Bolt hole threaded flange plate, flange specifications, model parameters

2025-5-26 -

What is a Steam pressure kettle flange cover? flange specifications, models, and parameters

2025-5-26 -

What is a Pipeline reducing flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to 15Cr forging and forging structure principle

2025-5-26 -

Introduction to Wind turbine flange free forging and forging structure principle

2025-5-26 -

What is a 12CrMoV forged parts? How much is the price of the forging?

2025-5-26