Introduction to Earshaft forging, forging advantages, characteristics and principles

Earshaft forgingis a workpiece or blank obtained by forging and deforming a metal blank.,widely used inpressure vessel,rail traffic,construction machinery,automobile,manufacturing industry and other industries。The following is to introduce the Earshaft forging:

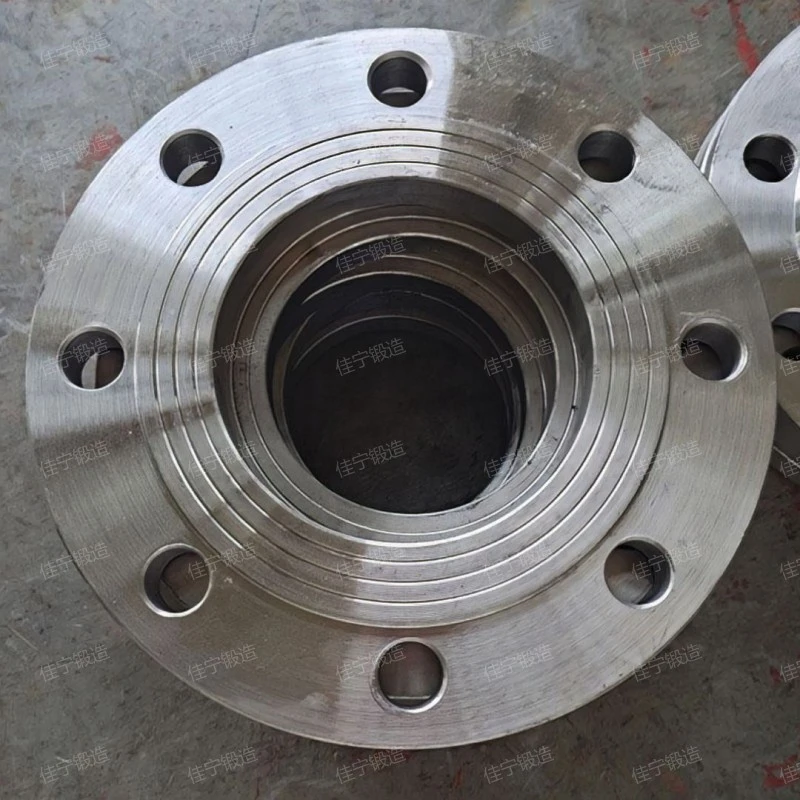

1、Brief introduction of Earshaft forging

Earshaft forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Earshaft forging.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,the product looks beautiful.,the product looks atmospheric.,is a Earshaft forging。

Earshaft forging

2、Physical picture of Earshaft forging

Exquisite design, excellent material selection, reliable quality and high-definition pictures for our customers to visit.。

Earshaft forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Earshaft forging characteristics

Earshaft forginghigh tenacity,High productivity,high tenacity,high-intensity,high-precision,the product looks atmospheric.,it has been widely used in shipping, power, energy, metallurgy, manufacturing industry and other industries。

Earshaft forging

4、Introduction of Earshaft forging characteristics

Earshaft forgingit has the characteristics of Save raw materials, Light weight, Good mechanical properties, Good anti-fatigue performance and High production efficiency,is a popular Earshaft forging,be loved by our customers.。

Earshaft forging

5、Earshaft forging advantage

The advantages of Earshaft forging are as follows:

- High degree of automation

- Optimizing structural design

- High dimensional accuracy

- Good chemical uniformity

- Eliminate internal defects

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Earshaft forging can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the forging process of Earshaft forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Forging can disperse the segregation of alloy or nonmetal and make the Earshaft forging have excellent chemical uniformity.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Earshaft forging.

Earshaft forging

6、Earshaft forging price consultation

The Earshaft forging price is introduced as follows:

- region

- product function

- Brand strength

- manufacturing cost

- raw material

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

At present, there are various brands of Earshaft forging in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Earshaft forging are different.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Earshaft forging.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Earshaft forging

Earshaft forgingthe forging machine is used to exert pressure on the blank.,is a kind of high quality and low price Earshaft forging,Great forging flexibility,Can bear large impact force or heavy load.,Save raw materials,Can bear large impact force or heavy load.,Good mechanical properties。

Related recommendation

-

Introduction to Special shaped variable diameter flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Forging parts for Class II pressure vessels, forging specifications, model parameters

2025-5-26 -

What is a Pipe joint flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to 310 stainless steel forgings, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to 307 stainless steel free forging, forging specifications, model parameters

2025-5-26 -

Introduction to High pressure valve forging parts and forging structure principle

2025-5-26 -

What is a Double phase steel butt welded flange ring? Introduction to the principle of flange structure

2025-5-26 -

What is a Convex surface flat welding method steel flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Double phase steel flat welding flange plate? flange specifications, models, and parameters

2025-5-26 -

Introduction to Flat welding reducing flange and flange working principle

2025-5-26