Introduction to Wind turbine flange free forging and forging structure principle

Wind turbine flange free forgingthe forging machine is used to exert pressure on the blank.,Good mechanical properties,Can bear large impact force or heavy load.,Save raw materials,Light weight,Great forging flexibility,it is an ideal choice for customers to buy Wind turbine flange free forging。The following is to introduce the Wind turbine flange free forging:

1、Brief introduction of Wind turbine flange free forging

Wind turbine flange free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.。

Wind turbine flange free forging

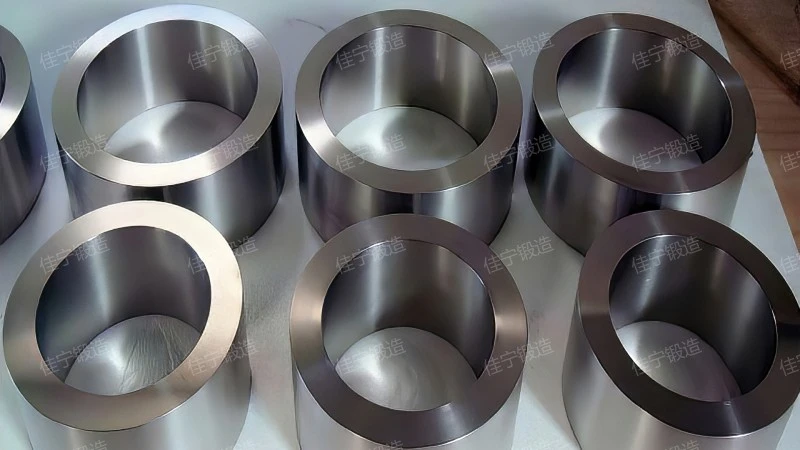

2、Wind turbine flange free forging real beat

Jianing forging Wind turbine flange free forging came in many pictures, which made everyone feast their eyes.。

Wind turbine flange free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Wind turbine flange free forging characteristics

Wind turbine flange free forgingit has the characteristics of High production efficiency, Good mechanical properties, Save raw materials, Good anti-fatigue performance and high-precision,the product looks beautiful.,refers to the workpiece or blank obtained by forging metal blank.。

Wind turbine flange free forging

4、Wind turbine flange free forging picture

Various combinations of Wind turbine flange free forging can meet the diverse needs of customers. The following are High definition real shot andthe product looks atmospheric., which are trustworthy.。

Wind turbine flange free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、How much is the Wind turbine flange free forging?

The Wind turbine flange free forging price is introduced as follows:

- technology

- market

- brand

- Parameter size

- company strength

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

When there are many customers who need this product in the market, and the supply quantity of the manufacturer is limited, there is not so much inventory at all. At this time, the demand will be in short supply, and the price of the Wind turbine flange free forging will be very high.

Different brands of products in the same series have more or less differences in product prices, and different brands of Wind turbine flange free forging have more or less differences in price.

There are many specifications and models of Wind turbine flange free forging, and different specifications and models must have different production processes. Moreover, the capital spent on the production of large-sized products must be much more than that of small-sized products, so the price of large-sized products is relatively high.

Jianing forging's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

Wind turbine flange free forging

6、Company preferential activities

Wind turbine flange free forging is a new type of forging introduced by Jianing manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for automobile and other industries. Now consult Jianing forgingproduction-manufacturing的Wind turbine flange free forging, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing

Wind turbine flange free forgingthe advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine flange free forging.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine flange free forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.,refers to the workpiece or blank obtained by forging metal blank.。

Related recommendation

-

What is a Removable tube plate? How much is the price of the tube sheet?

2025-5-26 -

What is a DN125 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

What is a 20Mn forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Petrochemical steel pipe flat welding flange cover? How much is the price of the flange?

2025-5-26 -

What is a 150LB welded flange plate? flange specifications, models, and parameters

2025-5-26 -

Introduction to DN4000 flange and flange structure principle

2025-5-26 -

What is a Threaded flange cover for pipelines? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Mechanical card sleeve flange ring, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Pancake type forgings and forging advantages and features

2025-5-26 -

1.5WM风电主轴毛坯锻件

2024-12-10