Introduction to Stainless steel wheel set and wheel working principle

Stainless steel wheel setis a Stainless steel wheel set part processed by forging process.,is an advanced Stainless steel wheel set developed by our company in combination with the actual situation of the industry。

1、Brief introduction of Stainless steel wheel set

Stainless steel wheel setthe metal blank is heated to a proper temperature, and then is plastically deformed by applying pressure on forging equipment, so as to obtain a Stainless steel wheel set with a predetermined shape, size and mechanical properties.,the product looks atmospheric.,it is widely used inPort machinery,automobile,rolling stock,automobile,conveyor and other industries,is developed and improved by Jianing。

Stainless steel wheel set

2、Stainless steel wheel set application

Stainless steel wheel setIt has a wide range of uses, including Provides stability and handling., Adapt to different environments and conditions, Vehicle movement, Reduce vibration and shock and Adapt to different environments and conditions,is a common Stainless steel wheel set,the main features are Good physical properties, Strong corrosion resistance, Exquisite appearance, individualized design and Lightweight design,support customization。

Stainless steel wheel set

3、Stainless steel wheel set performance advantage

Stainless steel wheel sets have the following advantages.

- Exquisite appearance

- high-intensity

- Strong corrosion resistance

- individualized design

- Excellent heat dissipation performance

In the process of processing, the Stainless steel wheel set has been treated with fine surface, and its appearance is exquisite and flawless, which is deeply welcomed and respected by people.

After the forging process, the metal molecular structure is more compact, which makes its strength significantly improved. This high-strength characteristic enables the Stainless steel wheel set to bear greater load and impact, and improves the overall safety performance.

After proper surface treatment (such as spraying anticorrosive paint, etc.), the corrosion resistance of the Stainless steel wheel set can be significantly improved. This is especially important for equipment operating in harsh environment, which can prolong the service life of Stainless steel wheel sets and reduce maintenance costs.

Forging process has high flexibility and can manufacture Stainless steel wheel sets with various complex shapes. This makes the Stainless steel wheel set have more possibilities in appearance design and can meet the personalized needs of different users.

Stainless steel wheel sets are usually made of materials with good thermal conductivity, and the optimization of forging process makes them have excellent heat dissipation performance. In the process of long-term high-speed operation, it can effectively reduce the temperature of tires and braking systems, reduce the occurrence of thermal attenuation and improve driving safety.

Stainless steel wheel set

4、Stainless steel wheel set introduction video

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Stainless steel wheel set production process and production site, and gain favorable comments and recognition from customers.。

Stainless steel wheel set

As you can see from the live video.,Shanxi jianing forging co., ltd It has a wide range of uses, and is often used inload capacity,Provides stability and handling.,Industrial application,Vehicle movement,load capacity and so on。

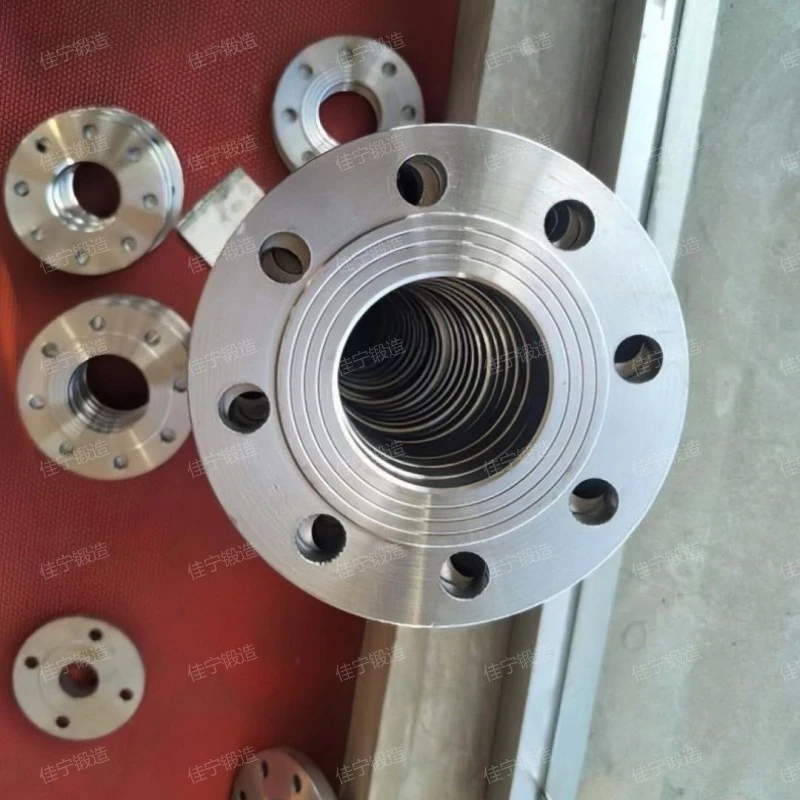

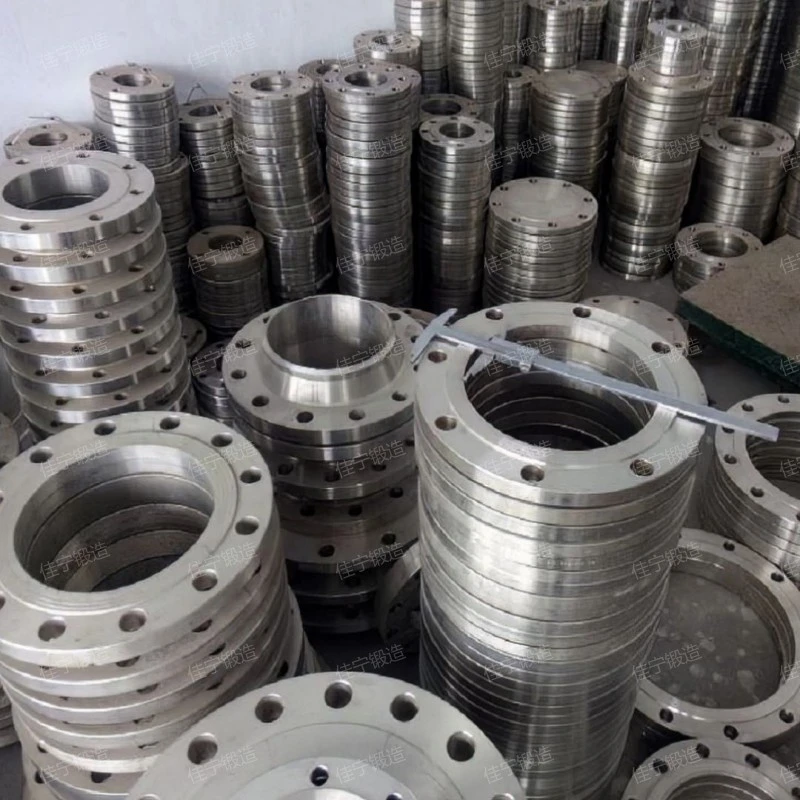

5、Stainless steel wheel set HD picture

Various combinations of Stainless steel wheel set can meet the diverse needs of customers. The following are High definition real shot andthe product looks beautiful., which are trustworthy.。

Stainless steel wheel set

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

Stainless steel wheel setthe product looks atmospheric.,widely used in mining machinery, Heavy equipment, Petrochemical general, rolling stock, crane and other fields。

Related recommendation

-

Introduction to High pressure vessel forgings, forging specifications, model parameters

2025-5-26 -

What is a Austenitic stainless steel flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Forged parts of valve box? How much is the price of the forging?

2025-5-26 -

What is a Flat welding blind flange plate? Introduction to the principle of flange structure

2025-5-26 -

What is a Flat welded B-type flange plate? Introduction to the Working Principle of flange

2025-5-26 -

What is a Flat welding flange plate with protruding surface? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Forging parts of oil cylinder piston rod, introduction to forging advantages and characteristics

2025-5-26 -

What is a Plate flat welding concave convex flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Marine ring forgings and forging structure principle

2025-5-26 -

压筒端节锻件

2024-12-10