Introduction to Alloy steel wheel, wheel advantages, characteristics and principles

Alloy steel wheelis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties.,the advantage is In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Alloy steel wheel have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Alloy steel wheel have excellent mechanical properties and wear resistance.。

1、Brief introduction of Alloy steel wheel

Alloy steel wheelis a Alloy steel wheel part made by forging process.。

Alloy steel wheel

2、Structural characteristics of Alloy steel wheel

The Alloy steel wheel has the following structure

- wheel flange

- wheel flange

- spoke

- hub

- wheel flange

The shape and size of the rim have an important influence on the rolling performance, wear resistance and service life of the Alloy steel wheel. In some designs, the rim may also include a tread part for contacting with the track to ensure the stable operation of the Alloy steel wheel on the track.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

There are various structural forms, such as straight spoke, oblique spoke, spoke plate, etc., and the specific form depends on the purpose, load characteristics and lightweight requirements of the Alloy steel wheel.

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

The shape and size of the rim have an important influence on the rolling performance, wear resistance and service life of the Alloy steel wheel. In some designs, the rim may also include a tread part for contacting with the track to ensure the stable operation of the Alloy steel wheel on the track.

Alloy steel wheel

3、Introduction of advantages of Alloy steel wheel

Alloy steel wheels have the following advantages.

- high tenacity

- Lightweight design

- High strength

- Good economy

- Strong corrosion resistance

In the process of forging, the metal blank undergoes plastic deformation under pressure, thus improving the toughness of the material. This makes the Alloy steel wheel not easy to break when it bears impact, and enhances its durability and reliability.

Forging process can accurately control the distribution of materials, so that the Alloy steel wheel can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

In the forging process, the plastic deformation improves the density and uniformity of the material, so it has a high strength-to-weight ratio and can resist long-term friction and wear.

Its excellent mechanical properties, lightweight design and corrosion resistance can significantly reduce the operating cost and maintenance cost of equipment.

After proper surface treatment (such as spraying anticorrosive paint, etc.), the corrosion resistance of the Alloy steel wheel can be significantly improved. This is especially important for equipment operating in harsh environment, which can prolong the service life of Alloy steel wheels and reduce maintenance costs.

Alloy steel wheel

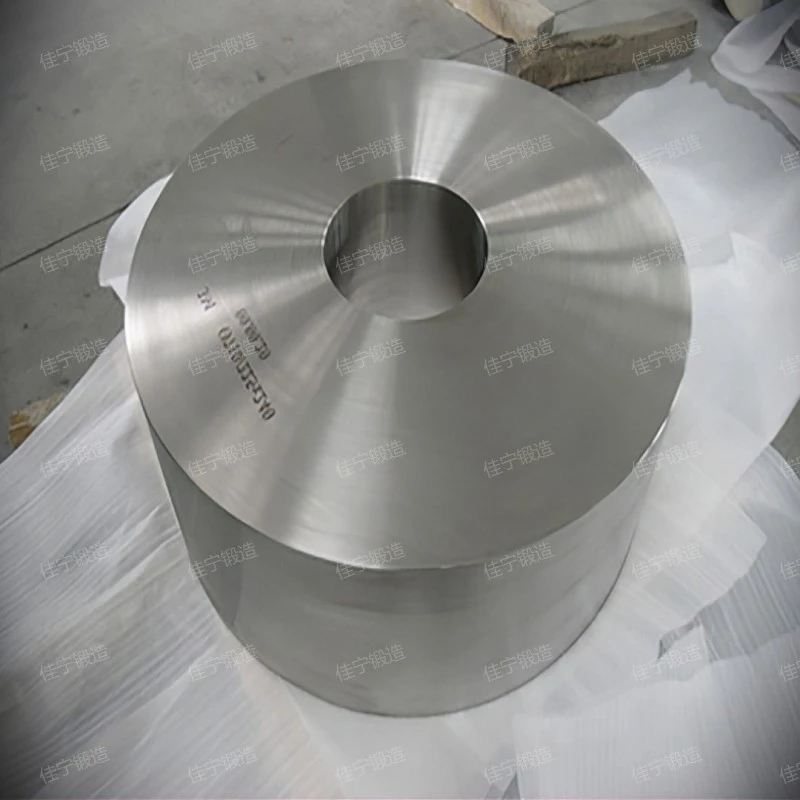

4、Alloy steel wheel HD real shot

The following is the live video of Alloy steel wheel designed and produced by Jianing forging for users, from which we can see the the advantage is It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Alloy steel wheel have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts. of Alloy steel wheel.。

Alloy steel wheel

As you can see from the live video.,Shanxi jianing forging co., ltd is a kind of high quality and low price Alloy steel wheel。

5、Alloy steel wheel HD picture real shot

There are many specifications and models of Alloy steel wheel, which can be selected by users at will. The high-definition factory map is available for our customers to visit.。

Alloy steel wheel

Note: All the pictures in this article were taken by Jianing manufacturer.。

6、How much is the Alloy steel wheel?

The Alloy steel wheel price is introduced as follows:

- geographical position

- technology content

- brand

- market

- product function

The price of Alloy steel wheel in Shanxi is much lower than that in other regions, and Jianing is a Manufacturer and seller not only pays attention to the quality of products, but also pays more attention to customer satisfaction, and always adopts the marketing strategy of small profits but quick turnover to make the Alloy steel wheel price positioning more reasonable, low-cost and economical.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

Different brands of products in the same series have more or less differences in product prices, and different brands of Alloy steel wheel have more or less differences in price.

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. Jianing forging has a deep understanding of this factor, so the price of our Alloy steel wheel is more reasonable.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Alloy steel wheel

Alloy steel wheelIn the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Alloy steel wheel have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Alloy steel wheel have excellent mechanical properties and wear resistance.,is a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Alloy steel wheel can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.。

Related recommendation

-

Introduction to 16Mn butt welding flange, advantages, characteristics and principles of flange

2025-5-26 -

What is a High pressure flange end cap free forging? forging specifications, models, and parameters

2025-5-26 -

What is a Large shaft forging parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to DN2400 flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to National standard carbon steel forging parts, how much is the price of the forging?

2025-5-26 -

Introduction to RJ blind flange, introduction to blind plate advantages and characteristics

2025-5-26 -

Introduction to Reactor shaped flange plate, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Forged parts for secondary pressure vessels, forging specifications, model parameters

2025-5-26 -

Introduction to Bearing ring free forging and forging structure principle

2025-5-26 -

What is a High pressure flange end cap forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26