Introduction to Stainless steel wheel forgings, wheel specifications, model parameters

Stainless steel wheel forgingsIs a workpiece or blank obtained by forging and deforming a metal blank.,This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Stainless steel wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Stainless steel wheel forgings have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.,it has been widely used in Basic parts, Petrochemical general, Heavy equipment, mining machinery, construction machinery and other industries,the product looks beautiful.,features include Lightweight design, Strong corrosion resistance, Excellent heat dissipation performance, Exquisite appearance and Superior mechanical properties。The following is to introduce the Stainless steel wheel forgings:

1、Brief introduction of Stainless steel wheel forgings

Stainless steel wheel forgingsby applying pressure to the metal blank, it produces plastic deformation, thus obtaining forgings with certain mechanical properties, shapes and sizes.,This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Stainless steel wheel forgings have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Stainless steel wheel forgings have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.,is a common Stainless steel wheel forgings,Mainly used forVehicle movement,load capacity,Vehicle movement,Industrial application andReduce vibration and shock,reliable quality,The price is low and affordable。

Stainless steel wheel forgings

2、Stainless steel wheel forgings structure composition

The Stainless steel wheel forgings structure is introduced as follows:

- hub

- wheel flange

- spoke

- hub

- wheel flange

Located in the center of the Stainless steel wheel forgings, it is used to connect the shaft head or install the bearing to bear the force and torque from the axle or transmission device.

Located at the outer edge of the Stainless steel wheel forgings, it is in direct contact with the road surface or through the tire.

There are various structural forms, such as straight spoke, oblique spoke, spoke plate, etc., and the specific form depends on the purpose, load characteristics and lightweight requirements of the Stainless steel wheel forgings.

Usually, mounting holes or flanges are designed for mounting bearings or directly connecting with axles to bear forces and moments from axles or transmission devices.

Located at the outer edge of the Stainless steel wheel forgings, it is the part where the Stainless steel wheel forgings contacts the road surface or installs tires.

Stainless steel wheel forgings

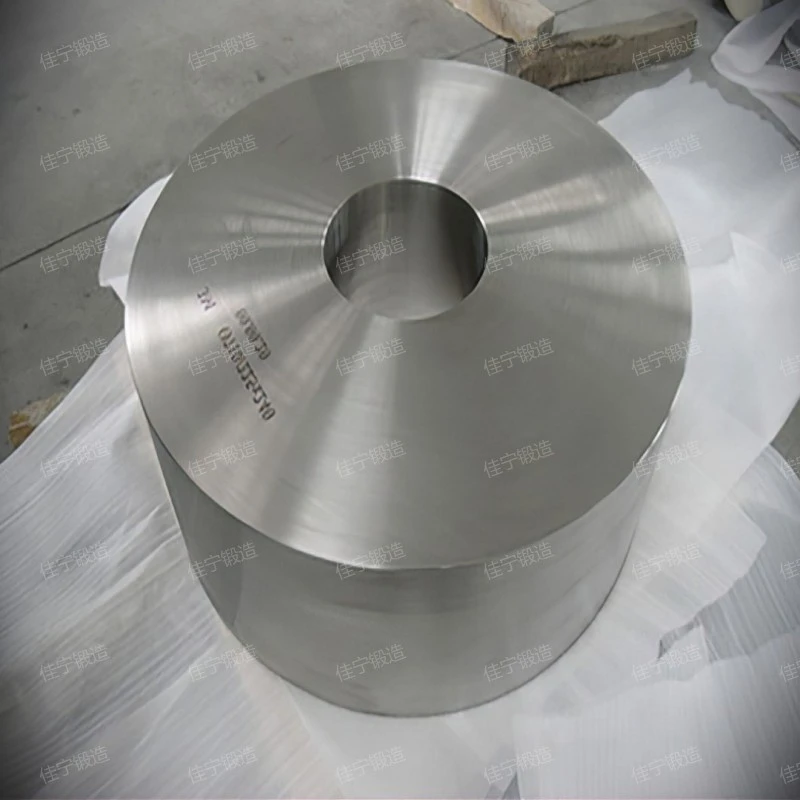

3、Stainless steel wheel forgings display

High-definition pictures of Jianing forging Stainless steel wheel forgings, showing different specifications and models.。

Stainless steel wheel forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Introduction of Stainless steel wheel forgings characteristics

Stainless steel wheel forgingsGood physical properties,individualized design,Lightweight design,individualized design,Good physical properties,is developed and improved by Jianing forging。

Stainless steel wheel forgings

5、Stainless steel wheel forgings structure

The Stainless steel wheel forgings structure is introduced as follows:

- spoke

- hub

- wheel flange

- spoke

- hub

The part connecting the hub and the rim plays the role of supporting and transmitting load.

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Located in the center of the Stainless steel wheel forgings, it is the key part of the connection between the Stainless steel wheel forgings and the axle.

Stainless steel wheel forgings

6、Real-time shooting in Jianing forging's production workshop

The finished products of the Stainless steel wheel forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Stainless steel wheel forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Stainless steel wheel forgingsthe main features are High strength, Exquisite appearance, Strong corrosion resistance, Superior mechanical properties and Excellent heat dissipation performance,is a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Stainless steel wheel forgingss can be divided into cold forging, warm forging and hot forging according to the temperature of the blank during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a temperature higher than the recrystallization temperature of the metal blank.,is a Stainless steel wheel forgings。

Related recommendation

-

Introduction to Wind turbine tower pipe flange, flange specifications, model parameters

2025-5-26 -

What is a C40 forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Rod forging and forging structure principle

2025-5-26 -

What is a H13 ring forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a High pressure oil cylinder end cap forging? Introduction to the Working Principle of forging

2025-5-26 -

冷轧辊锻件

2024-12-10 -

Introduction to Aluminum ring forgings, how much is the price of the forging?

2025-5-26 -

What is a Pressure vessel butt welded flange cover? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Flat ring gear forgings, advantages, characteristics and principles of ring gear

2025-5-26 -

Introduction to Forged parts for tertiary pressure vessels, advantages, characteristics and principles of forging

2025-5-26