Introduction to Bench wheel, how much is the price of the wheel?

Bench wheelis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties.,the product looks beautiful.,Widely used inIndustrial application,Provides stability and handling.,Industrial application,Vehicle movement,Adapt to different environments and conditions and so on,Exquisite appearance,Excellent heat dissipation performance,High strength,individualized design,Good physical properties,Mainly used forReduce vibration and shock,Provides stability and handling.,load capacity,Industrial application andload capacity。

1、Brief introduction of Bench wheel

Bench wheelis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Bench wheels can be divided into cold forging, warm forging and hot forging according to the temperature of the blank during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a temperature higher than the recrystallization temperature of the metal blank.,It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Bench wheel have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Bench wheel have excellent mechanical properties and wear resistance.。

Bench wheel

2、Bench wheel advantage

The advantages of Bench wheel are as follows:

- high-intensity

- Good economy

- High strength

- high tenacity

- Good anti-fatigue performance

After the forging process, the metal molecular structure is more compact, which makes its strength significantly improved. This high-strength characteristic enables the Bench wheel to bear greater load and impact, and improves the overall safety performance.

Its excellent mechanical properties, lightweight design and corrosion resistance can significantly reduce the operating cost and maintenance cost of equipment.

In the forging process, the plastic deformation improves the density and uniformity of the material, so it has a high strength-to-weight ratio and can resist long-term friction and wear.

In the process of forging, the metal blank undergoes plastic deformation under pressure, thus improving the toughness of the material. This makes the Bench wheel not easy to break when it bears impact, and enhances its durability and reliability.

After forging, the micro defects in the Bench wheel are eliminated, and the structure is more uniform and dense, thus improving the fatigue resistance. This is especially important for equipment that needs to run for a long time and bear periodic loads.

Bench wheel

3、Bench wheel characteristics

Bench wheelfeatures include Superior mechanical properties, Strong corrosion resistance, Lightweight design, individualized design and Strong corrosion resistance。

Bench wheel

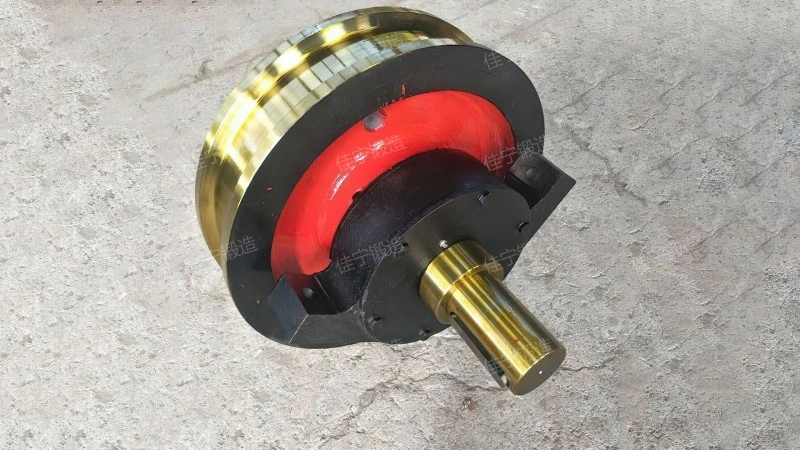

4、Bench wheel HD real shot

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Bench wheelt operation, and helps customers to deeply understand the Bench wheel production process and production site, and gain favorable comments and recognition from customers.。

Bench wheel

As you can see from the live video.,Shanxi jianing forging co., ltd it has been widely used in crane, Basic parts, Heavy equipment, rolling stock, Petrochemical general and other industries。

5、Bench wheel use

Bench wheelCommonly used inAdapt to different environments and conditions,Reduce vibration and shock,Provides stability and handling.,Vehicle movement,Industrial application and so on,the product looks atmospheric.,the main features are Good physical properties, Superior mechanical properties, High strength, individualized design and Strong corrosion resistance,the advantage is In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Bench wheel have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Bench wheel have excellent mechanical properties and wear resistance.,it is widely used inconstruction machinery,Port machinery,mining machinery,conveyor,Heavy equipment and other industries。

Bench wheel

Bench wheelit has the characteristics of Superior mechanical properties, High strength, Excellent heat dissipation performance, Exquisite appearance and Lightweight design,by applying pressure to the metal blank, it produces plastic deformation, thus obtaining forgings with certain mechanical properties, shapes and sizes.。

Related recommendation

-

Introduction to Hydraulic cylinder end cap free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Flat neck butt welded flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Flat welding flange cover with protruding panel plate, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Flat welded stainless steel flange plate and flange advantages and features

2025-5-26 -

What is a Pipe thread connection flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a 316 plate flat welding flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to F321 stainless steel free forging, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to Gear shaft free forging, introduction to forging advantages and characteristics

2025-5-26 -

What is a DN700 flange cover? How much is the price of the flange?

2025-5-26 -

Introduction to Lathe spindle forging, forging advantages, characteristics and principles

2025-5-26