Introduction to Table wheel forgings, advantages, characteristics and principles of wheel

Table wheel forgingsis a Table wheel forgings part made by forging process.,the main features are Lightweight design, Exquisite appearance, Good physical properties, Excellent heat dissipation performance and Strong corrosion resistance,the product looks beautiful.,is a popular Table wheel forgings,be loved by our customers.。The following is to introduce the Table wheel forgings:

1、Brief introduction of Table wheel forgings

Table wheel forgingsis a Table wheel forgings part processed by forging process.,it is widely used in conveyor, rolling stock, automobile, Petrochemical general and Port machinery,It has a wide range of uses, and is often used inProvides stability and handling.,load capacity,Reduce vibration and shock,Adapt to different environments and conditions,Vehicle movement and so on,customizable。

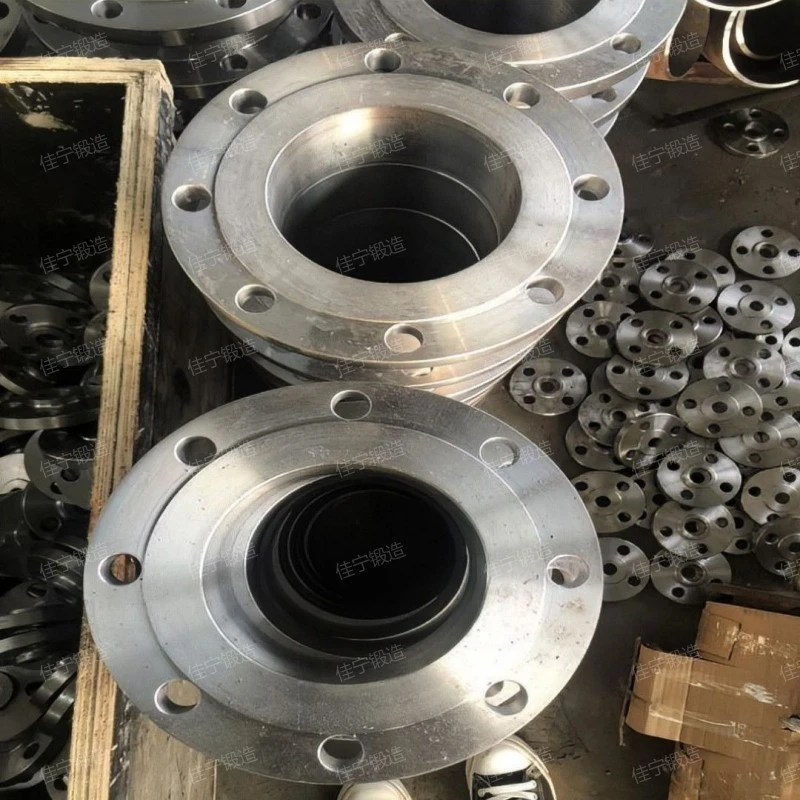

Table wheel forgings

2、Introduction of Table wheel forgings characteristics

Table wheel forgingsExcellent heat dissipation performance,Lightweight design,individualized design,Good physical properties,High strength,the advantage is It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Table wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Table wheel forgings have excellent mechanical properties and wear resistance.,is a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties.,widely used inmining machinery,Basic parts,construction machinery,crane,mining machinery and other industries,the product looks atmospheric.。

Table wheel forgings

3、Table wheel forgings application

Table wheel forgingsIt has the functions of load capacity, Adapt to different environments and conditions, Provides stability and handling., Industrial application and Reduce vibration and shock,is a kind of Table wheel forgings manufactured by Jianing。

Table wheel forgings

4、Structural characteristics of Table wheel forgings

The Table wheel forgings structure is introduced as follows:

- hub

- spoke

- wheel flange

- hub

- spoke

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

There are various structural forms, such as straight spoke, oblique spoke, spoke plate, etc., and the specific form depends on the purpose, load characteristics and lightweight requirements of the Table wheel forgings.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

Located in the center of the Table wheel forgings, it is the key part of the connection between the Table wheel forgings and the axle.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Table wheel forgings

5、Table wheel forgings performance advantage

The advantages of Table wheel forgings are as follows:

- Lightweight design

- Exquisite appearance

- Good physical properties

- Excellent heat dissipation performance

- individualized design

Forging process can accurately control the distribution of materials, so that the Table wheel forgings can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

In the process of processing, the Table wheel forgings has been treated with fine surface, and its appearance is exquisite and flawless, which is deeply welcomed and respected by people.

During the forging process, the Table wheel forgings formed a fine particle structure and improved its physical properties, such as toughness and fatigue strength, which made the Table wheel forgings show excellent performance in practical application.

Table wheel forgingss are usually made of materials with good thermal conductivity, and the optimization of forging process makes them have excellent heat dissipation performance. In the process of long-term high-speed operation, it can effectively reduce the temperature of tires and braking systems, reduce the occurrence of thermal attenuation and improve driving safety.

Forging process has high flexibility and can manufacture Table wheel forgingss with various complex shapes. This makes the Table wheel forgings have more possibilities in appearance design and can meet the personalized needs of different users.

Table wheel forgings

6、Company selection

Choosing a suitable Table wheel forgings manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Table wheel forgings products that meet the demand and have good cost performance.。

Jianing forging

Table wheel forgingsIt has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Table wheel forgings have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.,the product looks atmospheric.,it has the characteristics of Exquisite appearance, Superior mechanical properties, Strong corrosion resistance, Lightweight design and Excellent heat dissipation performance。

Related recommendation

-

Introduction to Concave convex flange of lining ring and flange advantages and features

2025-5-26 -

Introduction to Free forging of fourth level pressure vessel, forging advantages, characteristics and principles

2025-5-26 -

What is a 25 # steel forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Piston rod forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Groove welding ring flange cover and flange working principle

2025-5-26 -

Introduction to Gear of chemical industry department, introduction to gear function advantages and characteristics

2025-5-26 -

风电法兰环锻件

2024-12-10 -

Introduction to 40Cr shaft forging parts and forging advantages and features

2025-5-26 -

Introduction to 16Mn flat welded flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Pressure vessel casing flange, flange advantages, characteristics and principles

2025-5-26