What is a Crane wheel set? Introduction to the advantages and characteristics of wheel functions

Crane wheel setthe metal blank is heated to a proper temperature, and then is plastically deformed by applying pressure on forging equipment, so as to obtain a Crane wheel set with a predetermined shape, size and mechanical properties.。

1、Brief introduction of Crane wheel set

Crane wheel setIs a workpiece or blank obtained by forging and deforming a metal blank.,is a popular Crane wheel set,the advantage is It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crane wheel set have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.,reliable quality。

Crane wheel set

2、Introduction of advantages of Crane wheel set

Crane wheel sets have the following advantages.

- Strong corrosion resistance

- Lightweight design

- Excellent heat dissipation performance

- Good physical properties

- Good economy

After proper surface treatment (such as spraying anticorrosive paint, etc.), the corrosion resistance of the Crane wheel set can be significantly improved. This is especially important for equipment operating in harsh environment, which can prolong the service life of Crane wheel sets and reduce maintenance costs.

Forging process can accurately control the distribution of materials, so that the Crane wheel set can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

Crane wheel sets are usually made of materials with good thermal conductivity, and the optimization of forging process makes them have excellent heat dissipation performance. In the process of long-term high-speed operation, it can effectively reduce the temperature of tires and braking systems, reduce the occurrence of thermal attenuation and improve driving safety.

During the forging process, the Crane wheel set formed a fine particle structure and improved its physical properties, such as toughness and fatigue strength, which made the Crane wheel set show excellent performance in practical application.

Its excellent mechanical properties, lightweight design and corrosion resistance can significantly reduce the operating cost and maintenance cost of equipment.

Crane wheel set

3、Introduction of Crane wheel set characteristics

Crane wheel setit has the characteristics of Good physical properties, High strength, Superior mechanical properties, Lightweight design and Excellent heat dissipation performance,It is mostly used in Vehicle movement, Industrial application, Adapt to different environments and conditions, Vehicle movement, load capacity, Reduce vibration and shock and so on,is a Crane wheel set。

Crane wheel set

4、Crane wheel set structure composition

The Crane wheel set structure is introduced as follows:

- wheel flange

- hub

- spoke

- wheel flange

- hub

The shape and size of the rim have an important influence on the rolling performance, wear resistance and service life of the Crane wheel set. In some designs, the rim may also include a tread part for contacting with the track to ensure the stable operation of the Crane wheel set on the track.

Usually, mounting holes or flanges are designed for mounting bearings or directly connecting with axles to bear forces and moments from axles or transmission devices.

There are various structural forms of spokes, such as straight spoke, oblique spoke, spoke plate, etc. The specific form depends on the purpose, load characteristics and lightweight requirements of the Crane wheel set.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

Located in the center of the Crane wheel set, it is the key part of the connection between the Crane wheel set and the axle.

Crane wheel set

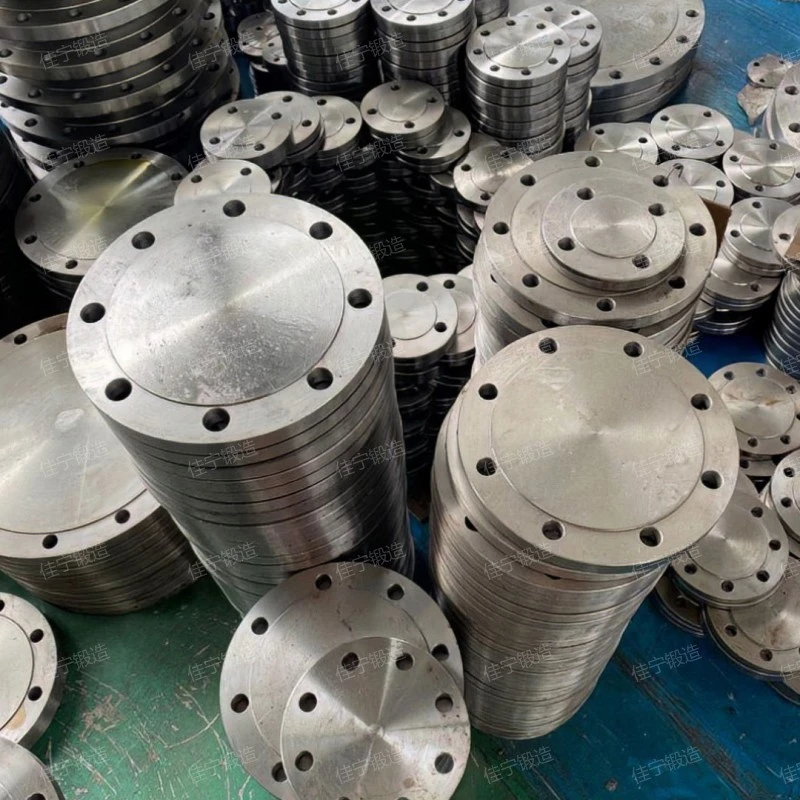

5、Crane wheel set work site real shot

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

Crane wheel set

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

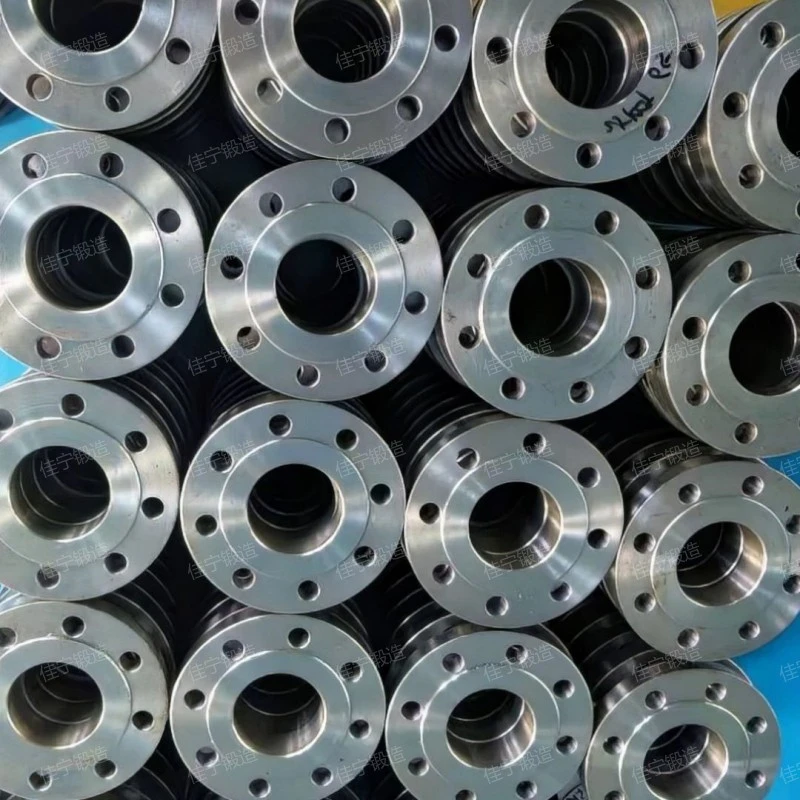

6、Crane wheel set field real shot

The following is the live video of Crane wheel set designed and produced by Jianing forging for users, from which we can see the the advantage is It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crane wheel set have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crane wheel set have excellent mechanical properties and wear resistance. of JianingCrane wheel set.。

Crane wheel set

As you can see from the live video.,Jianing is a kind of high quality and low price Crane wheel set。

Crane wheel setIt is a product series that integrates Vehicle movement, Reduce vibration and shock, Provides stability and handling., load capacity and Vehicle movement,It can be used for Industrial application, Adapt to different environments and conditions, Reduce vibration and shock, Adapt to different environments and conditions, load capacity, Provides stability and handling. and so on。

Related recommendation

-

Introduction to Welding thread flange cover, flange specifications, model parameters

2025-5-26 -

What is a Rotary bearing ring forging? How much is the price of the forging?

2025-5-26 -

What is a Concave convex surface threaded flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Horizontal tube plate, tube sheet specifications, model parameters

2025-5-26 -

What is a Flat welding full flat flange? Introduction to the principle of flange structure

2025-5-26 -

What is a DN80 flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Activity connection flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to PN400 flange plate, advantages, characteristics and principles of flange

2025-5-26 -

What is a Rotary cover flat welding flange? How much is the price of the flange?

2025-5-26 -

What is a 35Mn forging? forging specifications, models, and parameters

2025-5-26