What is a Crane wheel forgings? wheel specifications, models, and parameters

Crane wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Crane wheel forgingss can be divided into cold forging, warm forging and hot forging according to the temperature of the blank during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a temperature higher than the recrystallization temperature of the metal blank.,is a kind of high quality and low price Crane wheel forgings,it has been widely used in rolling stock, Petrochemical general, Port machinery, automobile, automobile and other industries。The following is to introduce the Crane wheel forgings:

1、Brief introduction of Crane wheel forgings

Crane wheel forgingsIs a workpiece or blank obtained by forging and deforming a metal blank.,has been favored by more and more customers.。

Crane wheel forgings

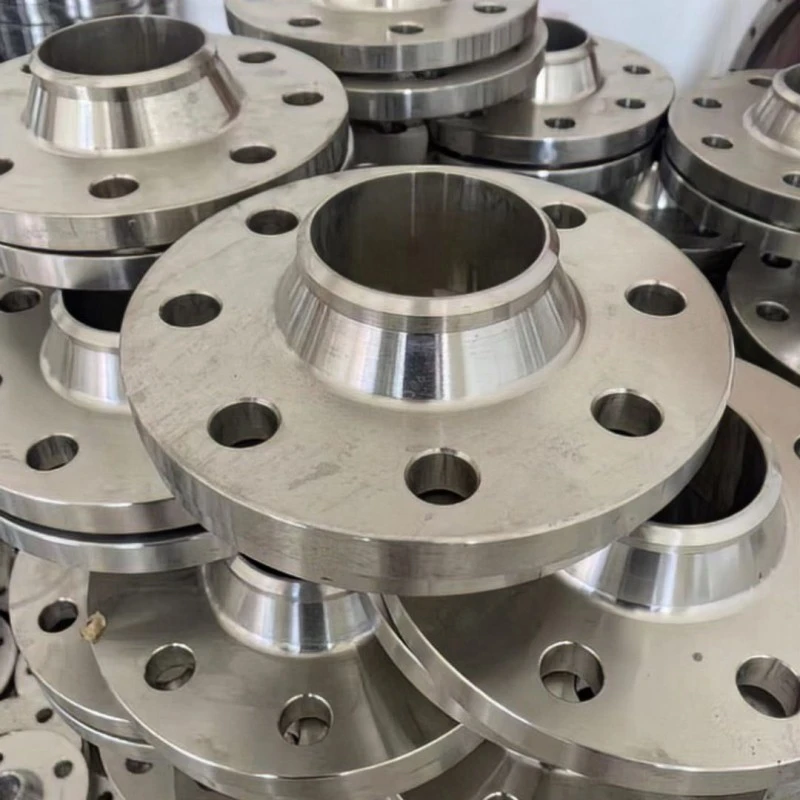

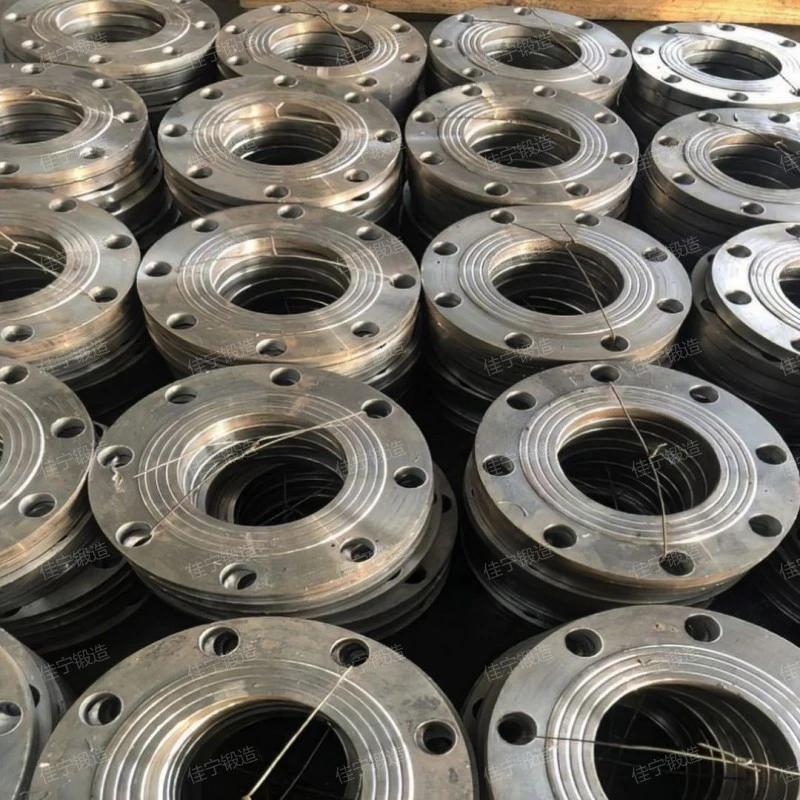

2、Crane wheel forgings HD picture

Crane wheel forgings styles and designs are diverse, specifications and models can be customized according to customer needs, providing high-definition pictures for new and old customers' reference.。

Crane wheel forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Structural characteristics of Crane wheel forgings

The Crane wheel forgings has the following structure

- wheel flange

- spoke

- wheel flange

- hub

- spoke

Located at the outer edge of the Crane wheel forgings, it is the part where the Crane wheel forgings contacts the road surface or installs tires.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Located at the outer edge of the Crane wheel forgings, it is in direct contact with the road surface or through the tire.

Located in the center of the Crane wheel forgings, it is used to connect the shaft head or install the bearing to bear the force and torque from the axle or transmission device.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Crane wheel forgings

4、Crane wheel forgings working site

You can buy Crane wheel forgings according to your needs and show you product videos.。

Crane wheel forgings

As you can see from the live video.,Jianing is a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Crane wheel forgings can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.。

5、Crane wheel forgings price consultation

The Crane wheel forgings price is introduced as follows:

- market competition

- technology

- Self quality

- Cost input

- product function

With the increasingly fierce competition of Crane wheel forgings, market factors have a certain influence on the price of Crane wheel forgings. When the demand in the market increases and the supply remains unchanged, the price will rise. On the contrary, the price will fall. When there is an increase in supply and the demand remains unchanged, the price will rise, on the contrary, the price will fall.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

The quality of the Crane wheel forgings is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the Crane wheel forgings price.

When the Crane wheel forgings is produced, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Crane wheel forgings

6、Introduction of Jianing forging Company

Jianing is a professional and large-scale Crane wheel forgings manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Crane wheel forgings manufacturer trusted by consumers at present.。

Jianing forging

Crane wheel forgingsis a Crane wheel forgings,the product looks atmospheric.,This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crane wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Crane wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.。

Related recommendation

-

What is a Alloy steel butt welded flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to DN125 flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Split flange plate, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Wind turbine bearing free forging and forging working principle

2025-5-26 -

Introduction to SAE welded flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

滚道锻件

2024-12-10 -

助燃风机轴毛坯锻件

2024-12-10 -

What is a Pressure pipeline flat welding flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to FF welded flange ring, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Structural steel free forging, how much is the price of the forging?

2025-5-26