What is a Wind turbine flange ring forging parts? Introduction to the advantages, characteristics, and principles of the forging

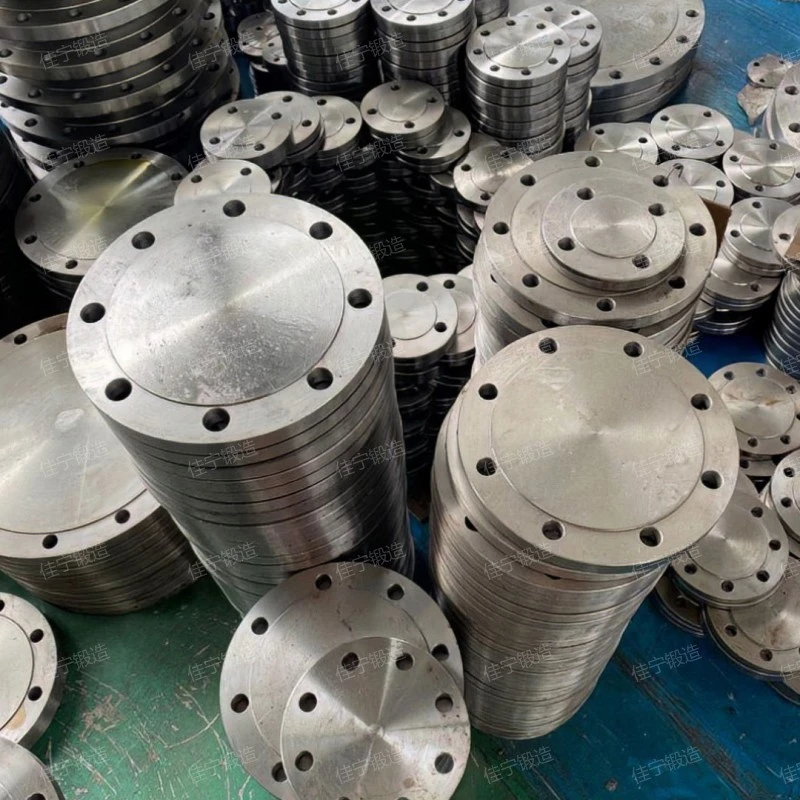

Wind turbine flange ring forging partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks atmospheric.,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine flange ring forging parts can be improved.。

1、Brief introduction of Wind turbine flange ring forging parts

Wind turbine flange ring forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the main features are high tenacity, high-intensity, Can bear large impact force or heavy load., High productivity and High productivity,the product looks beautiful.,is a popular Wind turbine flange ring forging parts,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine flange ring forging parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.。

Wind turbine flange ring forging parts

2、Introduction of advantages of Wind turbine flange ring forging parts

The advantages of Wind turbine flange ring forging parts are as follows:

- Replace other processing methods

- Reduce the amount of subsequent processing

- Meet the requirements of complex working conditions

- high tenacity

- High dimensional accuracy

In some cases, Wind turbine flange ring forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The forming precision of the Wind turbine flange ring forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

The Wind turbine flange ring forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The fiber structure of the Wind turbine flange ring forging parts is reasonably distributed, which improves the toughness of the material and enables the Wind turbine flange ring forging parts to bear greater impact force and alternating stress.

In the forging process of Wind turbine flange ring forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Wind turbine flange ring forging parts

3、Wind turbine flange ring forging parts introduction video

Speak directly with facts on the spot。

Wind turbine flange ring forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd is a kind of high quality and low price Wind turbine flange ring forging parts。

4、Functional advantages of Wind turbine flange ring forging parts

Wind turbine flange ring forging partss have the following advantages.

- high-intensity

- high-intensity

- Replace other processing methods

- Optimizing structural design

- high tenacity

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In some cases, Wind turbine flange ring forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Wind turbine flange ring forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

The fiber structure of the Wind turbine flange ring forging parts is reasonably distributed, which improves the toughness of the material and enables the Wind turbine flange ring forging parts to bear greater impact force and alternating stress.

Wind turbine flange ring forging parts

5、Video analysis of Wind turbine flange ring forging parts

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Wind turbine flange ring forging partst operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Wind turbine flange ring forging parts

As you can see from the live video.,Jianing forging Light weight,Great forging flexibility,high-intensity,Save raw materials,high-precision。

Wind turbine flange ring forging partsthe product looks atmospheric.,it is widely used in energy, rail traffic, pressure vessel, shipping and manufacturing industry。

Related recommendation

-

Introduction to Threaded welded flange ring, flange specifications, model parameters

2025-5-26 -

齿轮模锻件

2024-12-10 -

What is a 304 threaded flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Cone roller shaft free forging, how much is the price of the forging?

2025-5-26 -

Introduction to Hot work die steel forgings, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Heat exchanger connecting pipe flat welding flange ring? How much is the price of the flange?

2025-5-26 -

Introduction to Blind butt welded flange cover, how much is the price of the flange?

2025-5-26 -

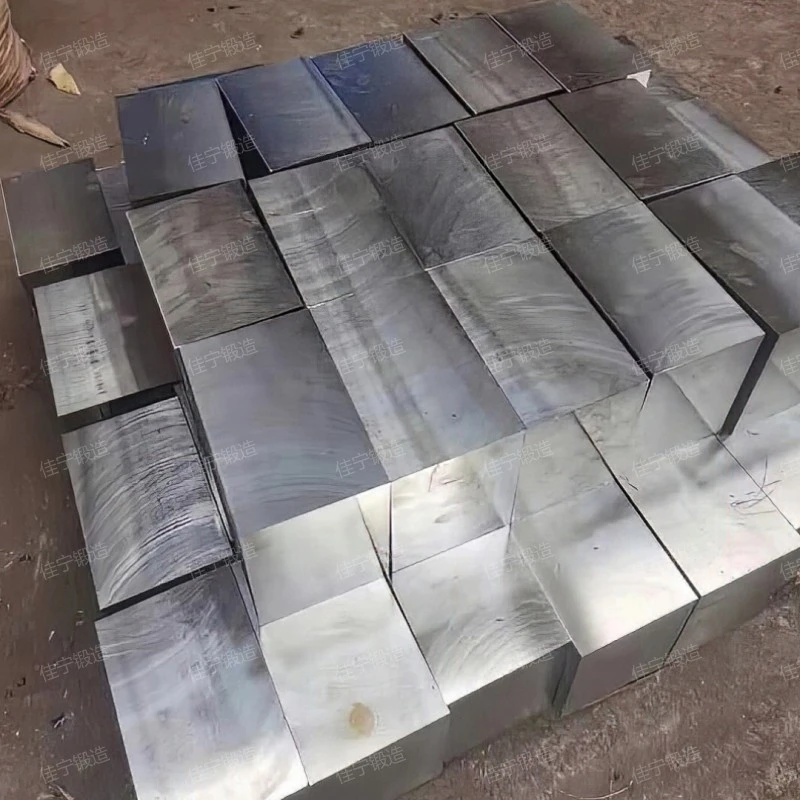

Introduction to Block free forging, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Docking thread flange, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Flat plate flat welded pipe flange ring, flange specifications, model parameters

2025-5-26