Introduction to Wind turbine flange forging, introduction to forging function advantages and characteristics

Wind turbine flange forgingrefers to the workpiece or blank obtained by forging metal blank.,is a kind of high quality and low price Wind turbine flange forging,it has been widely used in automobile, power, metallurgy, rail traffic, rail traffic and other industries,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine flange forging.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine flange forging can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine flange forging can be improved.,features include High productivity, Good anti-fatigue performance, Great forging flexibility, high tenacity and high-precision。

1、Brief introduction of Wind turbine flange forging

Wind turbine flange forgingis a workpiece or blank obtained by forging and deforming a metal blank.,the product looks beautiful.,is a Wind turbine flange forging,widely used in manufacturing industry, energy, pressure vessel, construction machinery, automobile and other fields,Cheap and high quality。

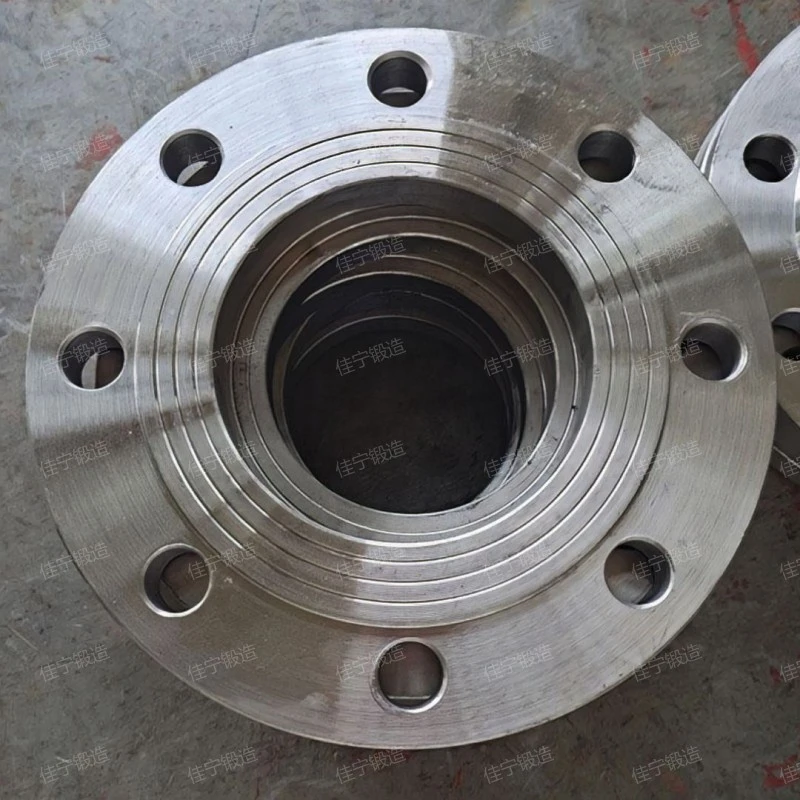

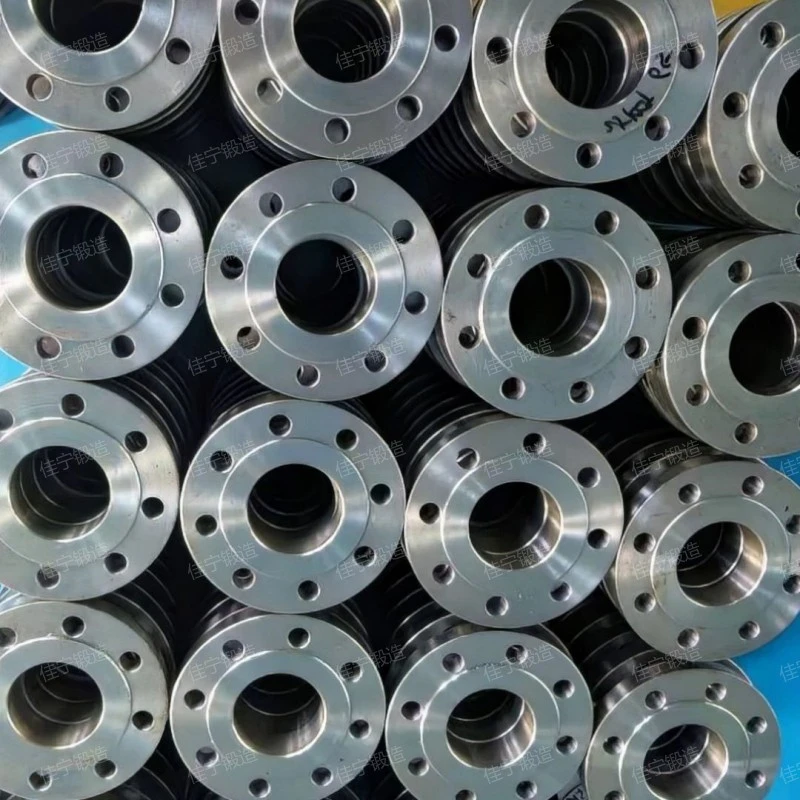

Wind turbine flange forging

2、Wind turbine flange forging characteristics

Wind turbine flange forgingit has the characteristics of Can bear large impact force or heavy load., Light weight, High production efficiency, Great forging flexibility and High productivity,can be customized according to user's needs.。

Wind turbine flange forging

3、Wind turbine flange forging performance advantage

Wind turbine flange forgings have the following advantages.

- Good chemical uniformity

- High degree of automation

- Eliminate internal defects

- Perfect quality assurance system

- Good fatigue resistance.

Forging can disperse the segregation of alloy or nonmetal and make the Wind turbine flange forging have excellent chemical uniformity.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Wind turbine flange forging.

In the process of Wind turbine flange forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Wind turbine flange forging.

The particle flow inside the Wind turbine flange forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

Wind turbine flange forging

4、Wind turbine flange forging field real shot

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Wind turbine flange forging

As you can see from the live video.,Shanxi jianing forging co., ltd it can be used in shipping, metallurgy, power, war industry, power and other industries。

5、Introduction of Wind turbine flange forging characteristics

Wind turbine flange forgingthe main features are Light weight, high tenacity, high-intensity, high-precision and Good anti-fatigue performance,it is widely used in metallurgy, energy, automobile, manufacturing industry, shipping and other industries,the product looks beautiful.,it is widely used inrail traffic,construction machinery,war industry,pressure vessel,construction machinery and other industries,After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine flange forging.。

Wind turbine flange forging

6、How much is the Wind turbine flange forging?

The Wind turbine flange forging price is introduced as follows:

- Cost input

- regional advantages

- Reasonable cost

- service

- quality

The production cost is mainly the purchase of raw materials. Jianing attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, Jianing forging strives to reduce the input cost of products, and customers are very satisfied with this.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing the site is located at:Xinzhou, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. Jianing forging has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing Wind turbine flange forging manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Wind turbine flange forging price can meet the purchasing needs of customers.

The price of Wind turbine flange forging is affected by the quality of products. Only when the products are of good quality can we create greater profits for customers and recover the costs for customers as soon as possible. However, products with good quality have a lot of investment in technology, manpower and time, so their prices are higher than those of ordinary products. On the contrary, the products of general quality are equal in effort and gain, and the sales price is also low. But there are exceptions. Many manufacturers often adopt the mode of small profits but quick turnover. If customers can choose products with high cost performance, it is a good choice for long-term investment.

Wind turbine flange forging

Wind turbine flange forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks atmospheric.。

Related recommendation

-

Introduction to 316L plate flat welding flange, how much is the price of the flange?

2025-5-26 -

蒸压釜盖锻件

2024-12-10 -

What is a Concave flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a 35Mn free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to Convex concave flange plate and flange structure principle

2025-5-26 -

What is a Flat welded pipe plate flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Q355E alloy free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

长轴锻件

2024-12-10 -

Introduction to 45Mn forged parts, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Free forging of oil cylinder rod head, how much is the price of the forging?

2025-5-26