Introduction to Valve gland free forging, how much is the price of the forging?

Valve gland free forgingthe forging machine is used to exert pressure on the blank.,widely used in pressure vessel, energy, construction machinery, manufacturing industry, automobile and other fields,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve gland free forging.,is a popular Valve gland free forging,it can be used in shipping, automobile, power, shipping, rail traffic and other industries。

1、Brief introduction of Valve gland free forging

Valve gland free forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging, its structure and mechanical properties can be improved.,it is an ideal choice for customers to buy Valve gland free forging。

Valve gland free forging

2、Valve gland free forging characteristics

Valve gland free forgingthe main features are Light weight, Good anti-fatigue performance, high-precision, High productivity and Can bear large impact force or heavy load.,After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve gland free forging can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,the product looks beautiful.。

Valve gland free forging

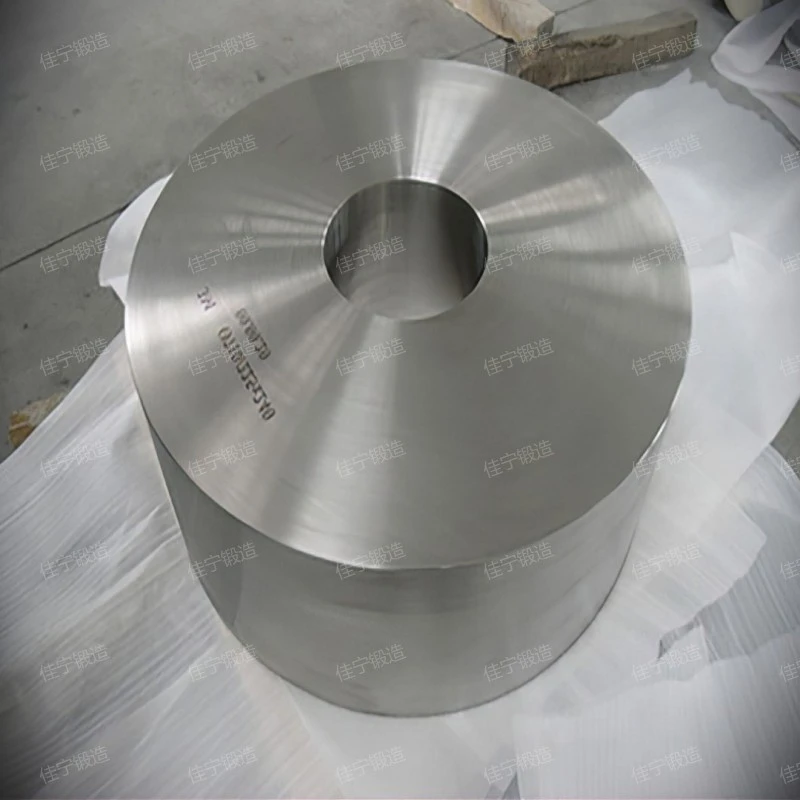

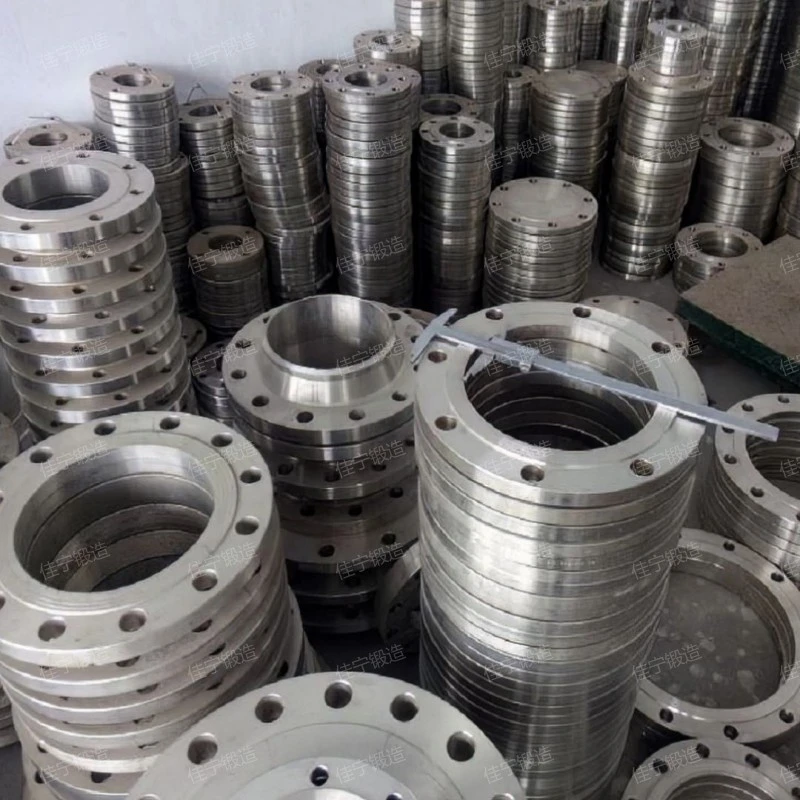

3、Valve gland free forging real beat

Overview of high-definition pictures,the product looks beautiful., different specifications and models。

Valve gland free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Introduction of advantages of Valve gland free forging

Valve gland free forgings have the following advantages.

- high tenacity

- Good chemical uniformity

- Meet the requirements of complex working conditions

- Good fatigue resistance.

- Eliminate internal defects

The fiber structure of the Valve gland free forging is reasonably distributed, which improves the toughness of the material and enables the Valve gland free forging to bear greater impact force and alternating stress.

Forging can disperse the segregation of alloy or nonmetal and make the Valve gland free forging have excellent chemical uniformity.

The Valve gland free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The particle flow inside the Valve gland free forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Valve gland free forging.

Valve gland free forging

5、Introduction of Valve gland free forging characteristics

Valve gland free forgingit has the characteristics of high tenacity, high-intensity, high-intensity, High productivity and Save raw materials,is a popular Valve gland free forging。

Valve gland free forging

6、Valve gland free forging price advantage

The Valve gland free forging price is introduced as follows:

- cost of production

- product function

- raw material

- service

- quality

The cost of manufacturing Valve gland free forging varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Valve gland free forging price and service can meet the actual needs of customers.

Quality is one of the fundamental and important factors that affect the price. Usually, the better the quality of the Valve gland free forging, the higher its price, and the quality is mainly affected by the manufacturing process, raw material materials, workers' experience and other factors. Therefore, if customers want to buy products with better quality, they can conduct on-the-spot visits to the product manufacturers to learn more about the scale, manufacturing process and production capacity of the manufacturers, so as to comprehensively judge the quality of the products.

Valve gland free forging

Valve gland free forgingit is widely used in war industry, energy, construction machinery, pressure vessel, metallurgy and other industries,the product looks atmospheric.,the advantage is By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve gland free forging can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve gland free forging.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

Related recommendation

-

Introduction to Reducing flat welding flange and flange structure principle

2025-5-26 -

What is a DN1100 flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Flat welding plate flange, flange advantages, characteristics and principles

2025-5-26 -

What is a Aluminum alloy ring free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Hydraulic cylinder end cap forging? Introduction to the principle of forging structure

2025-5-26 -

Introduction to Flat welded steel flange cover with protruding surface, advantages, characteristics and principles of flange

2025-5-26 -

What is a Free forging of pressure vessel cylinder? forging specifications, models, and parameters

2025-5-26 -

Introduction to Hydraulic cylinder base free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Orifice plate welded flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Quick opening butt welding flange and flange advantages and features

2025-5-26