What is a Aluminum alloy ring free forging? Introduction to the advantages and characteristics of forging functions

Aluminum alloy ring free forgingrefers to the workpiece or blank obtained by forging metal blank.。The following is to introduce the Aluminum alloy ring free forging:

1、Brief introduction of Aluminum alloy ring free forging

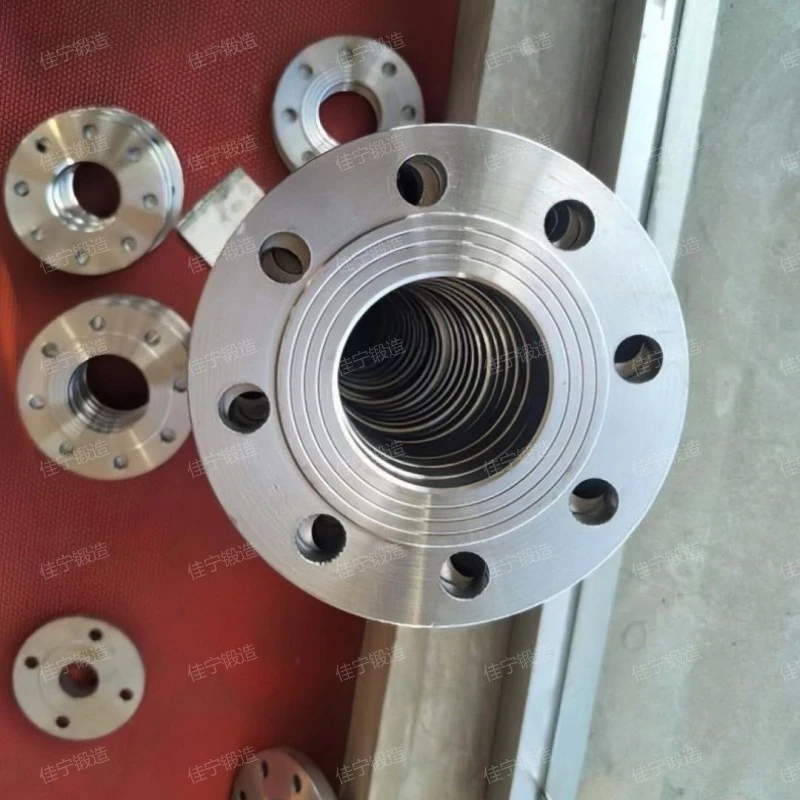

Aluminum alloy ring free forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,is a Aluminum alloy ring free forging,is a kind of high quality and low price Aluminum alloy ring free forging,it is widely used in manufacturing industry, rail traffic, power, metallurgy and pressure vessel,is carefully developed by Jianing forging combined with advanced technology。

Aluminum alloy ring free forging

2、Functional advantages of Aluminum alloy ring free forging

Aluminum alloy ring free forgings have the following advantages.

- high-intensity

- Good chemical uniformity

- Meet the requirements of complex working conditions

- Reduce the amount of subsequent processing

- High dimensional accuracy

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging can disperse the segregation of alloy or nonmetal and make the Aluminum alloy ring free forging have excellent chemical uniformity.

The Aluminum alloy ring free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The forming precision of the Aluminum alloy ring free forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the forging process of Aluminum alloy ring free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Aluminum alloy ring free forging

3、Aluminum alloy ring free forging video

Speak directly with facts on the spot。

Aluminum alloy ring free forging

As you can see from the live video.,Jianing the product looks beautiful.。

4、Introduction of advantages of Aluminum alloy ring free forging

The advantages of Aluminum alloy ring free forging are as follows:

- High degree of automation

- Improve material utilization rate

- Replace other processing methods

- Eliminate internal defects

- Reduce the amount of subsequent processing

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of Aluminum alloy ring free forging production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

In some cases, Aluminum alloy ring free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Aluminum alloy ring free forging.

The forming precision of the Aluminum alloy ring free forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Aluminum alloy ring free forging

5、Aluminum alloy ring free forging characteristics

Aluminum alloy ring free forgingit has the characteristics of Great forging flexibility, Good anti-fatigue performance, Save raw materials, high-intensity and Save raw materials,the product looks atmospheric.。

Aluminum alloy ring free forging

6、Aluminum alloy ring free forging price

The Aluminum alloy ring free forging price is introduced as follows:

- Product technology

- manufacturing cost

- Product configuration difference

- Manufacturer scale

- regional difference

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The difference in Aluminum alloy ring free forging configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

There are many Aluminum alloy ring free forging manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

If the location of the manufacturer is superior, its transportation will be more convenient. Jianing forging the address is located at:Xinzhou has convenient transportation, which provides a good convenience for the transportation of Aluminum alloy ring free forging.

Aluminum alloy ring free forging

Aluminum alloy ring free forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,it is widely used in war industry, rail traffic, power, manufacturing industry, energy and other industries,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Aluminum alloy ring free forging.。

Related recommendation

-

Introduction to 316L convex butt welding flange and flange advantages and features

2025-5-26 -

What is a Quick release flange cover? Introduction to the Working Principle of flange

2025-5-26 -

轧环锻件

2024-12-10 -

起重机车轮锻件

2024-12-10 -

What is a Ring connection face welding flange ring? flange specifications, models, and parameters

2025-5-26 -

风机轴毛坯

2024-12-10 -

Introduction to Q235A carbon steel forged parts, forging specifications, model parameters

2025-5-26 -

What is a Alloy steel flange plate? How much is the price of the flange?

2025-5-26 -

What is a Plate type flat welding convex flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to 316L plate flat welding flange ring and flange advantages and features

2025-5-26