Introduction to Valve gland forging parts, advantages, characteristics and principles of forging

Valve gland forging partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,it is an ideal choice for customers to buy Valve gland forging parts。The following is to introduce the Valve gland forging parts:

1、Brief introduction of Valve gland forging parts

Valve gland forging partsrefers to the workpiece or blank obtained by forging metal blank.。

Valve gland forging parts

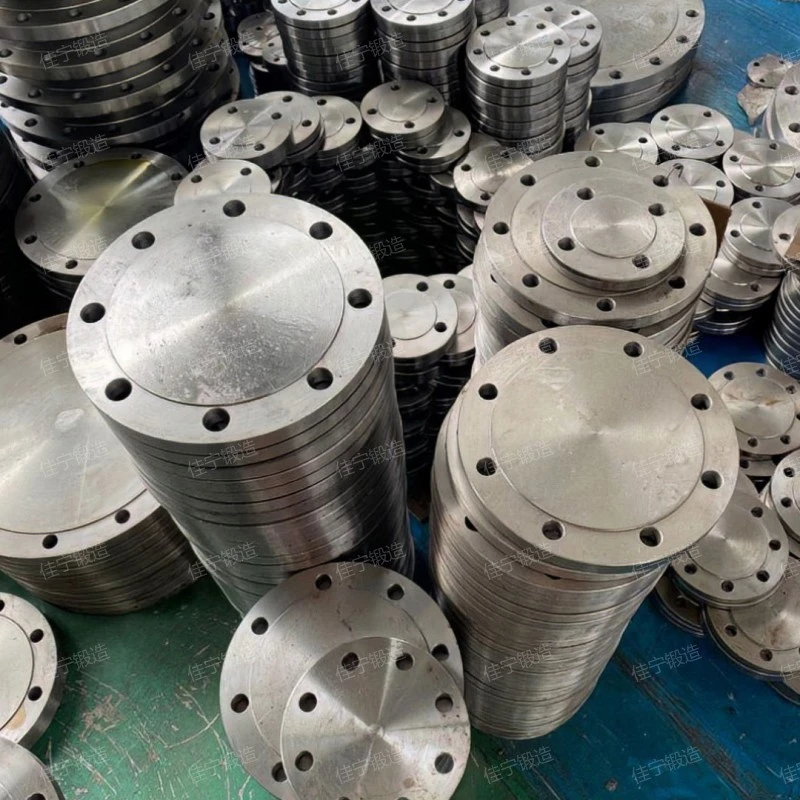

2、Valve gland forging parts picture

The finished products of the Valve gland forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Valve gland forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Valve gland forging parts explanation video

Speak directly with facts on the spot。

Valve gland forging parts

As you can see from the live video.,Jianing forging it has been widely used in manufacturing industry, rail traffic, power, automobile, war industry and other industries。

4、Functional advantages of Valve gland forging parts

The advantages of Valve gland forging parts are as follows:

- Optimizing structural design

- Replace other processing methods

- Improve material utilization rate

- High dimensional accuracy

- Eliminate internal defects

On the premise of ensuring the design strength, through reasonable structural design, the Valve gland forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In some cases, Valve gland forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

In the process of Valve gland forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

In the forging process of Valve gland forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Valve gland forging parts.

Valve gland forging parts

5、Valve gland forging parts field real shot

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Valve gland forging parts production process and production site, and gain favorable comments and recognition from customers.。

Valve gland forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd high tenacity,High production efficiency,Light weight,Good anti-fatigue performance,Can bear large impact force or heavy load.。

6、Valve gland forging parts price concessions

The Valve gland forging parts price is introduced as follows:

- market demand

- technology content

- Manufacturer's strength

- deploy

- Model specification

The market has great fluctuation, which is also the key factor that leads to the imbalance and instability of supply and demand, and then leads to great changes in product prices. Only after a comprehensive understanding and investigation of the market can we make a reasonable decision, and then we can formulate a Valve gland forging parts price sales plan that customers are satisfied with, and the main reason for its price rationality is also reflected here.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

There are many Valve gland forging parts manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Valve gland forging parts are closely related. Jianing has comprehensively measured the configuration and sales price of products when designing Valve gland forging parts, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

There are various specifications and models of Valve gland forging parts, and the performance of different specifications and models is quite different. Customers should choose products with appropriate specifications and models according to the actual situation.

Valve gland forging parts

Valve gland forging partsthe forging machine is used to exert pressure on the blank.,is a common Valve gland forging parts。

Related recommendation

-

Introduction to Flat welded steel flange cover with raised surface plate and flange structure principle

2025-5-26 -

Introduction to Irregular flange and flange structure principle

2025-5-26 -

Introduction to Cylinder forgings and forging advantages and features

2025-5-26 -

Introduction to Three-hole gear ring, how much is the price of the ring gear?

2025-5-26 -

What is a Threaded bolt hole flange plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Forged hydraulic cylinder end cover and forging structure principle

2025-5-26 -

发电机护环锻件

2024-12-10 -

Introduction to Steel pipe plate flat welding flange and flange structure principle

2025-5-26 -

Introduction to Quick installation blind plate and blind plate advantages and features

2025-5-26 -

What is a Round threaded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26