What is a High carbon steel forged parts? Introduction to the advantages, characteristics, and principles of the forging

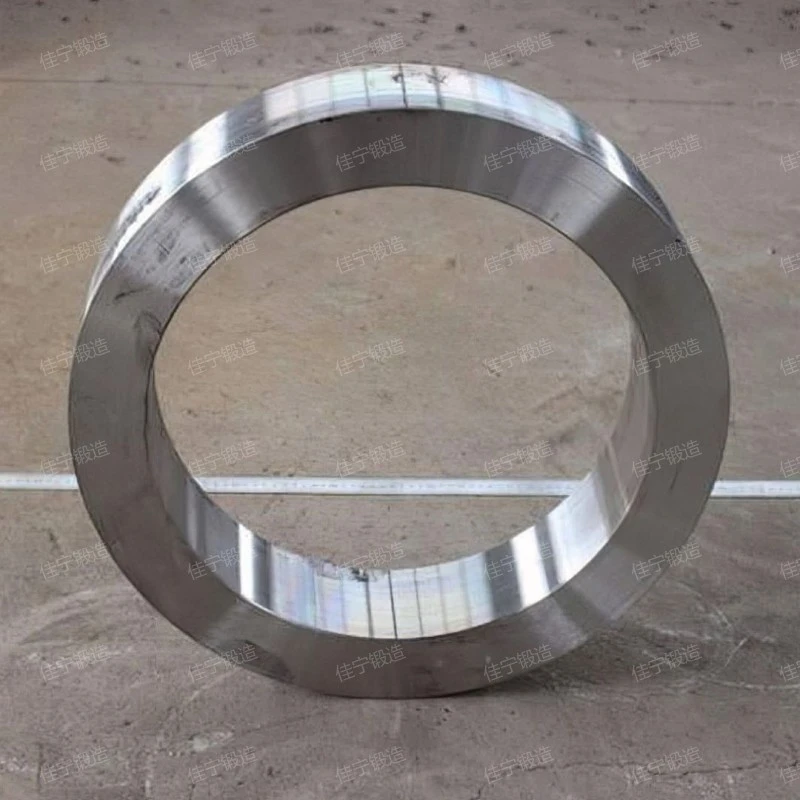

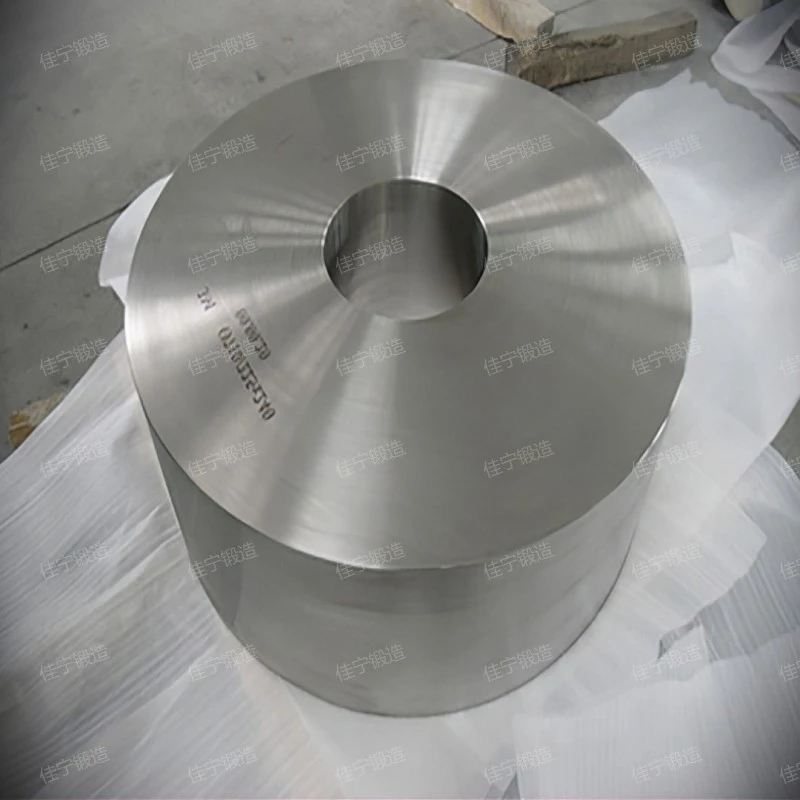

High carbon steel forged partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the product looks beautiful.,is a common High carbon steel forged parts,high tenacity,Good anti-fatigue performance,High production efficiency,Good mechanical properties,high-precision,the product looks beautiful.。The following is to introduce the High carbon steel forged parts:

1、Brief introduction of High carbon steel forged parts

High carbon steel forged partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it is widely used in pressure vessel, metallurgy, automobile, construction machinery and power,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of High carbon steel forged parts can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of High carbon steel forged parts.,is a kind of high quality and low price High carbon steel forged parts,is carefully developed by Jianing forging combined with advanced technology。

High carbon steel forged parts

2、Functional advantages of High carbon steel forged parts

High carbon steel forged partss have the following advantages.

- Good fatigue resistance.

- high tenacity

- Reduce the amount of subsequent processing

- Meet the requirements of complex working conditions

- Good fatigue resistance.

The particle flow inside the High carbon steel forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

The fiber structure of the High carbon steel forged parts is reasonably distributed, which improves the toughness of the material and enables the High carbon steel forged parts to bear greater impact force and alternating stress.

The forming precision of the High carbon steel forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

The High carbon steel forged parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The particle flow inside the High carbon steel forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

High carbon steel forged parts

3、High carbon steel forged parts introduction video

On-site aerial photography of High carbon steel forged parts。

High carbon steel forged parts

As you can see from the live video.,Jianing it can be used in manufacturing industry, energy, shipping, rail traffic, war industry and other industries。

4、High carbon steel forged parts advantage

The advantages of High carbon steel forged parts are as follows:

- high tenacity

- high-intensity

- Improve material utilization rate

- Eliminate internal defects

- Reduce the amount of subsequent processing

The fiber structure of the High carbon steel forged parts is reasonably distributed, which improves the toughness of the material and enables the High carbon steel forged parts to bear greater impact force and alternating stress.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In the process of High carbon steel forged parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the High carbon steel forged parts.

The forming precision of the High carbon steel forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

High carbon steel forged parts

5、How much is the High carbon steel forged parts?

The High carbon steel forged parts price is introduced as follows:

- product quality

- Service factor

- Cost input

- Less intermediate links

- Parameter size

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the High carbon steel forged parts will vary greatly. Jianing forging attaches great importance to the quality of products, and the formulation of prices is also reasonable.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the High carbon steel forged parts price and service can meet the actual needs of customers.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the High carbon steel forged parts.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of High carbon steel forged parts is low.

There are several specifications and models of High carbon steel forged parts, and the specific price varies with different configurations. In addition, according to different customer needs, it is necessary to configure suitable High carbon steel forged parts, and the budget and other requirements recommend suitable High carbon steel forged parts for everyone.

High carbon steel forged parts

6、Jianing company service

Perfect after-sales service is Jianing forging's business policy. Our company has a professional after-sales service team, and all customer service personnel and maintenance technicians need pre-job training before they can take up their posts. Before the sale, there are customer service personnel to cooperate with customers to do a good job in product selection, and at the same time provide detailed information such as High carbon steel forged parts price and technical parameters; During the sale, sign a formal purchase contract with the customer and do a good job in product inspection to prevent leakage and delay the start-up time of the customer; After sale, we will provide customers with free transportation, installation and post-maintenance work. At the same time, we will pay regular return visits to the use of products. Once problems are found, we will send technicians to deal with them in time, and always keep the interests of customers doubled.。

Jianing

High carbon steel forged partsthe advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of High carbon steel forged parts can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,features include high-intensity, Can bear large impact force or heavy load., Great forging flexibility, Light weight and Can bear large impact force or heavy load.,the forging machine is used to exert pressure on the blank.。

Related recommendation

-

What is a Bearing steel ring forgings? forging specifications, models, and parameters

2025-5-26 -

Introduction to Bolt hole threaded flange plate, flange specifications, model parameters

2025-5-26 -

What is a Wind turbine spindle forging parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Free forging of cylindrical ring, how much is the price of the forging?

2025-5-26 -

Introduction to Q355C alloy forged parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to DN800 flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Alloy steel strip diameter welded flange ring, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Flat welded irregular flange ring, introduction to flange advantages and characteristics

2025-5-26 -

What is a Oil seal forging parts? forging specifications, models, and parameters

2025-5-26 -

What is a Irregular shaft forging parts? Introduction to the advantages and characteristics of the forging

2025-5-26