What is a Wind turbine spindle forging parts? Introduction to the advantages, characteristics, and principles of the forging

Wind turbine spindle forging partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。The following is to introduce the Wind turbine spindle forging parts:

1、Brief introduction of Wind turbine spindle forging parts

Wind turbine spindle forging partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,it has been widely used in war industry, pressure vessel, automobile, shipping, metallurgy and other industries。

Wind turbine spindle forging parts

2、Introduction of Wind turbine spindle forging parts characteristics

Wind turbine spindle forging partsfeatures include High productivity, Great forging flexibility, Save raw materials, High production efficiency and high tenacity,is a Wind turbine spindle forging parts。

Wind turbine spindle forging parts

3、Wind turbine spindle forging parts characteristics

Wind turbine spindle forging partsSave raw materials,Good mechanical properties,Can bear large impact force or heavy load.,high tenacity,Good anti-fatigue performance,the product looks beautiful.,it can be used in shipping, rail traffic, power, metallurgy, construction machinery and other industries,After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine spindle forging parts.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine spindle forging parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,is a popular Wind turbine spindle forging parts。

Wind turbine spindle forging parts

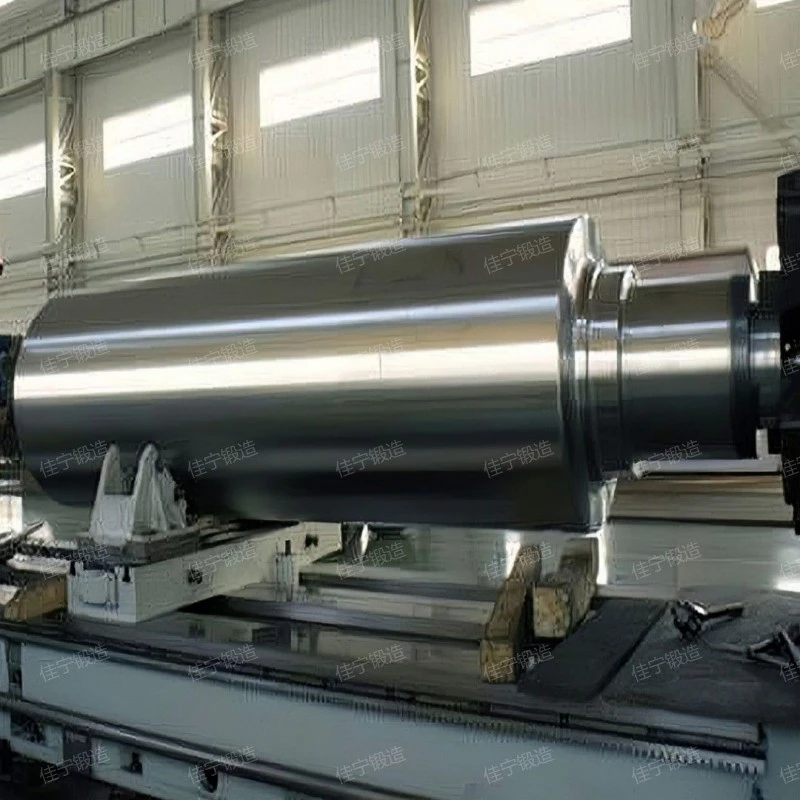

4、Physical picture of Wind turbine spindle forging parts

Wind turbine spindle forging parts are widely used. The following is a multi-directional display diagram of Wind turbine spindle forging parts, and the details are full of quality and intelligence.。

Wind turbine spindle forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Wind turbine spindle forging parts video live broadcast

On-site aerial photography of Wind turbine spindle forging parts。

Wind turbine spindle forging parts

As you can see from the live video.,Jianing refers to the workpiece or blank obtained by forging metal blank.。

6、Wind turbine spindle forging parts price concessions

The Wind turbine spindle forging parts price is introduced as follows:

- select a qualified person

- Sales model

- product function

- company strength

- deploy

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. Jianing forging's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

Products of the same style, different configurations, the product price is definitely different, therefore, the Wind turbine spindle forging parts price is affected by the configuration, and the price varies.

Wind turbine spindle forging parts

Wind turbine spindle forging partsit can be used in war industry, energy, pressure vessel, automobile, manufacturing industry and other industries,the product looks atmospheric.,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine spindle forging parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine spindle forging parts can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。

Related recommendation

-

What is a Secondary pressure vessel forging parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Special alloy free forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Forged parts of aluminum alloy pressure vessels? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

DG20Mn舵杆锻件

2024-12-10 -

轧管机轧辊轴锻件

2024-12-10 -

What is a Pipe threaded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Q235 convex flange plate, introduction to flange advantages and characteristics

2025-5-26 -

台级环锻件

2024-12-10 -

Introduction to Flat bearing free forging, introduction to forging advantages and characteristics

2025-5-26 -

What is a Chemical Department Plate Flat Welding Flange? flange specifications, models, and parameters

2025-5-26