Introduction to 30Mn2 forging, forging advantages, characteristics and principles

30Mn2 forgingrefers to the workpiece or blank obtained by forging metal blank.,can be customized according to user's needs.。The following is to introduce the 30Mn2 forging:

1、Brief introduction of 30Mn2 forging

30Mn2 forgingthe forging machine is used to exert pressure on the blank.,is a common 30Mn2 forging,it has the characteristics of Great forging flexibility, Good mechanical properties, Good anti-fatigue performance, High production efficiency and Great forging flexibility。

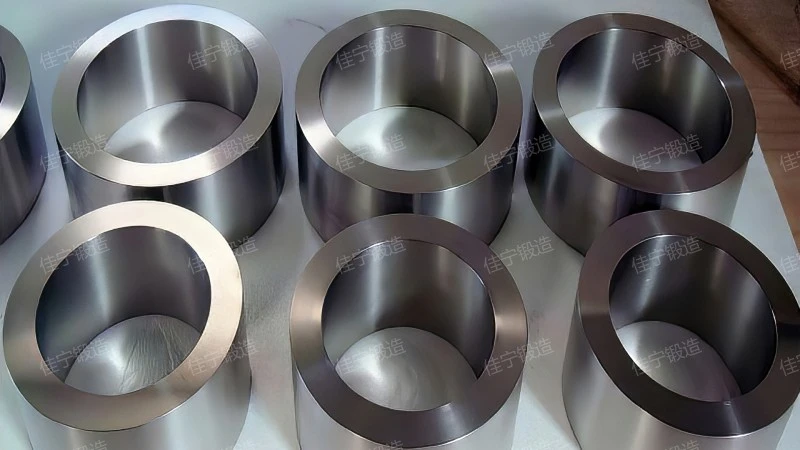

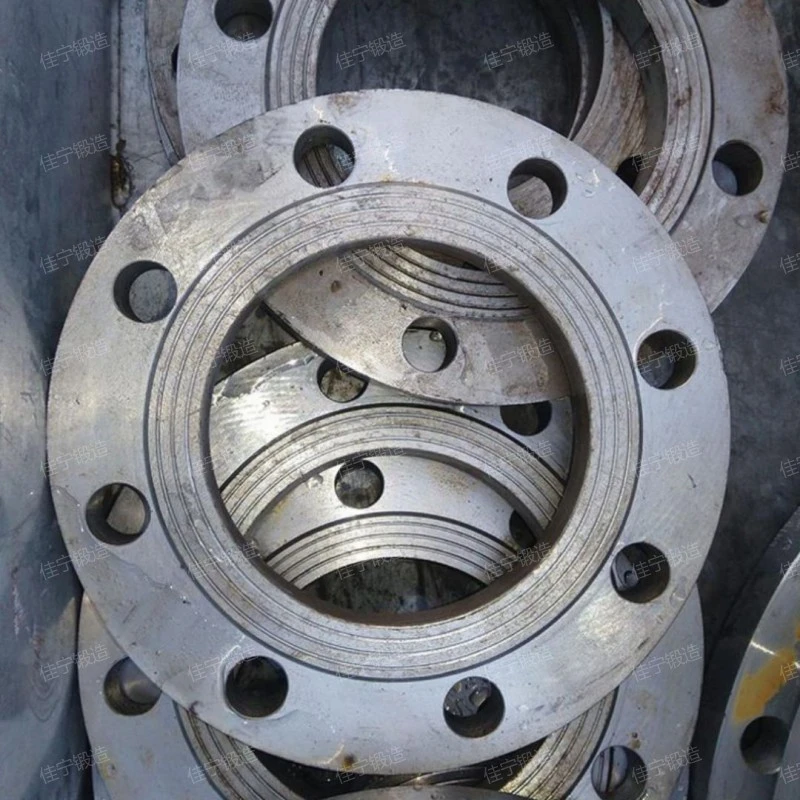

30Mn2 forging

2、30Mn2 forging advantage

The advantages of 30Mn2 forging are as follows:

- Meet the requirements of complex working conditions

- High dimensional accuracy

- Reduce the amount of subsequent processing

- Meet the requirements of complex working conditions

- Good fatigue resistance.

The 30Mn2 forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the forging process of 30Mn2 forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The forming precision of the 30Mn2 forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

The 30Mn2 forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The particle flow inside the 30Mn2 forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

30Mn2 forging

3、Introduction of 30Mn2 forging characteristics

30Mn2 forgingHigh productivity,high tenacity,Good mechanical properties,Can bear large impact force or heavy load.,Save raw materials,is a popular 30Mn2 forging,is carefully developed by Jianing forging combined with advanced technology。

30Mn2 forging

4、Introduction of advantages of 30Mn2 forging

30Mn2 forgings have the following advantages.

- Good chemical uniformity

- High degree of automation

- High dimensional accuracy

- Eliminate internal defects

- Perfect quality assurance system

Forging can disperse the segregation of alloy or nonmetal and make the 30Mn2 forging have excellent chemical uniformity.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the forging process of 30Mn2 forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the 30Mn2 forging.

In the process of 30Mn2 forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the 30Mn2 forging.

30Mn2 forging

5、Video analysis of 30Mn2 forging

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site 30Mn2 forgingt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

30Mn2 forging

As you can see from the live video.,Jianing forging it is widely used in automobile, war industry, metallurgy, energy, automobile and other industries。

30Mn2 forgingit has been widely used in construction machinery, shipping, rail traffic, energy, power and other industries,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks atmospheric.。

Related recommendation

-

Introduction to Pressure vessel gear forgings, introduction to gear advantages and characteristics

2025-5-26 -

Introduction to Integral pipe plate flange, introduction to tube sheet advantages and characteristics

2025-5-26 -

What is a Forging parts for fourth level pressure vessels? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Automobile gear, gear advantages, characteristics and principles

2025-5-26 -

What is a Chemical flat welding flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to internal gear and gear advantages and features

2025-5-26 -

What is a Wind power column flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to C50 free forging and forging advantages and features

2025-5-26 -

What is a Perforated gear forgings? Introduction to the Working Principle of gear

2025-5-26 -

Introduction to Flat welding flange ring on groove surface and flange advantages and features

2025-5-26