Introduction to Pressure vessel gear forgings, introduction to gear advantages and characteristics

Pressure vessel gear forgingsis an important part of transmission mechanical devices.,it has been widely used in petrochemical industry, Construction machinery and equipment, mining machinery, petrochemical industry, automobile making and other industries,It is a product series that integrates Improve transmission accuracy and efficiency, Transmit motion and power., Bear load and impact, Improve transmission accuracy and efficiency and Transmit motion and power.,the advantage is Improve production efficiency and material utilization: Forging process can usually form multiple Pressure vessel gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.、After forging process, the internal structure is compact, and there are no defects such as porosity and slag inclusion, so the bearing capacity is strong.、In forging process, the dimensional accuracy and shape accuracy of the Pressure vessel gear forgings can be ensured through accurate die design and control. Compared with casting and other processes, the forging Pressure vessel gear forgings has lower error and more accurate tooth profile, which is helpful to improve the stability and efficiency of the transmission system.、By forging process, metal materials are plastically deformed at high temperature and high pressure, which eliminates internal defects, such as porosity and slag inclusion, and makes the material structure more dense. This compact structure makes the Pressure vessel gear forgings have higher strength and toughness, can bear greater load and impact, and improves the durability and reliability of the Pressure vessel gear forgings.、Forging process not only improves the strength and toughness of the Pressure vessel gear forgings, but also helps to improve the mechanical properties of the Pressure vessel gear forgings.,The tooth shape accuracy is high.,Thick teeth,Good wear resistance,Uniform material,The rim is toothed.。

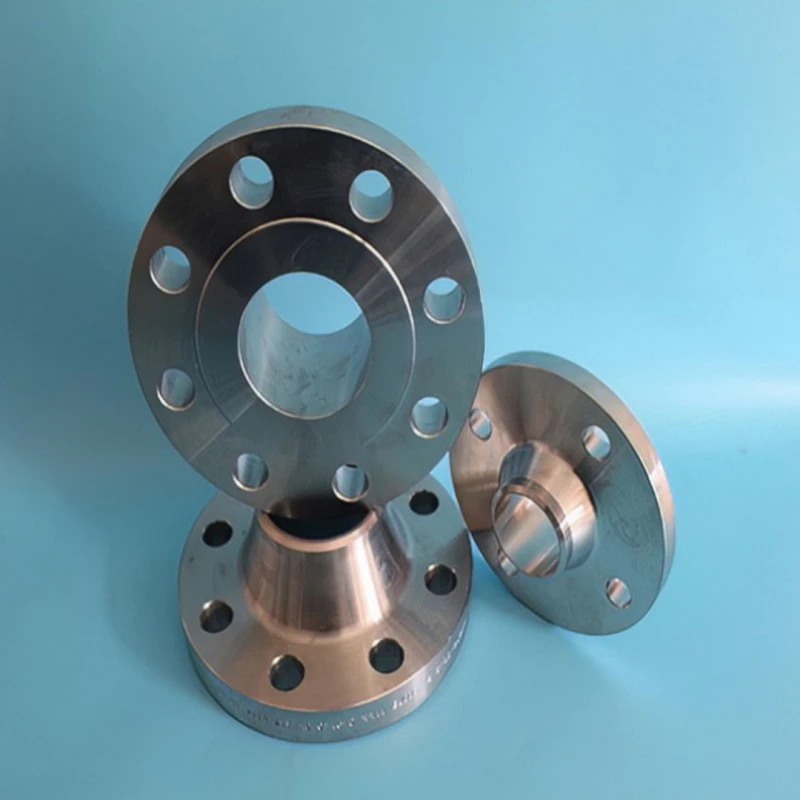

1、Brief introduction of Pressure vessel gear forgings

Pressure vessel gear forgingsis a Pressure vessel gear forgings made by forging process, with specific tooth shape and size to meet the requirements of transmission machinery.,the product looks atmospheric.。

Pressure vessel gear forgings

2、Introduction of Pressure vessel gear forgings characteristics

Pressure vessel gear forgingsLong service life,Wide range of applications,High precision,Strong bearing capacity,High hardness,customizable。

Pressure vessel gear forgings

3、Introduction of advantages of Pressure vessel gear forgings

Pressure vessel gear forgingss have the following advantages.

- High precision

- Improve the overall mechanical properties.

- Improve production efficiency and material utilization rate

- Good wear resistance

- Improve the overall mechanical properties.

In forging process, the dimensional accuracy and shape accuracy of the Pressure vessel gear forgings can be ensured through accurate die design and control. Compared with casting and other processes, the forging Pressure vessel gear forgings has lower error and more accurate tooth profile, which is helpful to improve the stability and efficiency of the transmission system.

Forging process not only improves the strength and toughness of the Pressure vessel gear forgings, but also helps to improve the mechanical properties of the Pressure vessel gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

Forging process can usually form multiple Pressure vessel gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.

The application of alloy steel material and heat treatment technology makes the Pressure vessel gear forgings surface hard and wear resistant.

Forging process not only improves the strength and toughness of the Pressure vessel gear forgings, but also helps to improve the mechanical properties of the Pressure vessel gear forgings. The improvement of these properties is helpful to improve the overall performance and stability of the transmission system.

Pressure vessel gear forgings

4、Pressure vessel gear forgings introduction video

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Pressure vessel gear forgings production process and production site, and gain favorable comments and recognition from customers.。

Pressure vessel gear forgings

As you can see from the live video.,Shanxi jianing forging co., ltd the product looks atmospheric.。

5、How much is the Pressure vessel gear forgings?

The Pressure vessel gear forgings price is introduced as follows:

- region

- product function

- brand

- raw material

- Cost input

If the location of the manufacturer is superior, its transportation will be more convenient. Jianing address:Xinzhou has convenient transportation, which provides a good convenience for the transportation of Pressure vessel gear forgings.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different brands of products in the same series have more or less differences in product prices, and different brands of Pressure vessel gear forgings have more or less differences in price.

The quality of material selection is one of the main factors that directly affect the Pressure vessel gear forgings. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Pressure vessel gear forgings just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

Pressure vessel gear forgings

6、Jianing forging workshop real shot

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Pressure vessel gear forgings production process and production site, and gain favorable comments and recognition from customers.。

Pressure vessel gear forgings

As you can see from the live video.Jianing forging is a popular Pressure vessel gear forgings。

Pressure vessel gear forgingsis an important part of transmission mechanical devices.,Commonly used inBear load and impact,Improve transmission accuracy and efficiency,Transmit motion and power.,Bear load and impact,Improve transmission accuracy and efficiency and so on。

Related recommendation

-

What is a Convex flat welded steel flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a flat flange? flange specifications, models, and parameters

2025-5-26 -

What is a 24 inch flange plate? Introduction to the principle of flange structure

2025-5-26 -

What is a Quick opening flange? flange specifications, models, and parameters

2025-5-26 -

What is a Integral flat welding flange plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Q235 flat welding flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to 16MnC alloy free forging and forging advantages and features

2025-5-26 -

Introduction to Q345 pressure vessel butt welding flange, how much is the price of the flange?

2025-5-26 -

What is a Stainless steel tube plate? Introduction to the advantages, characteristics, and principles of the tube sheet

2025-5-26 -

Introduction to B-shaped tube plate and tube sheet advantages and features

2025-5-26