Introduction and functional advantages of Q355E alloy forgings

Q355E alloy forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,can be customized according to user's needs.。The following is to introduce the Q355E alloy forgings:

1、Brief introduction of Q355E alloy forgings

Q355E alloy forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

Q355E alloy forgings

2、Q355E alloy forgings advantage

The advantages of Q355E alloy forgings are as follows:

- Eliminate internal defects

- Improve material utilization rate

- Good chemical uniformity

- high-intensity

- High degree of automation

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Q355E alloy forgings.

In the process of Q355E alloy forgings production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Q355E alloy forgings have excellent chemical uniformity.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Q355E alloy forgings

3、Q355E alloy forgings video live broadcast

Speak directly with facts on the spot。

Q355E alloy forgings

As you can see from the live video.,Shanxi jianing forging co., ltd is a popular Q355E alloy forgings。

4、Q355E alloy forgings characteristics

Q355E alloy forgingsthe main features are high-intensity, High productivity, Save raw materials, Light weight and High production efficiency,the product looks beautiful.,it is an ideal choice for customers to buy Q355E alloy forgings。

Q355E alloy forgings

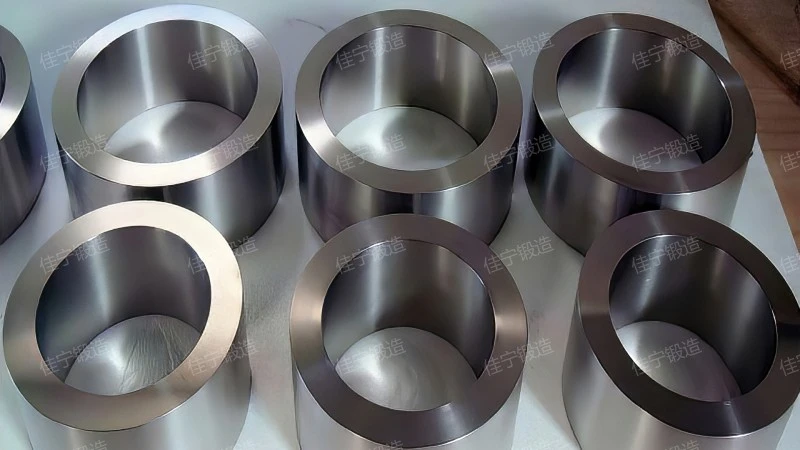

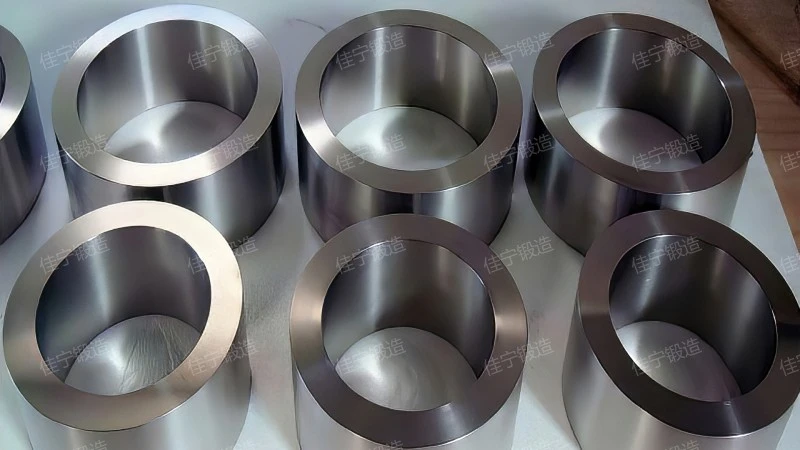

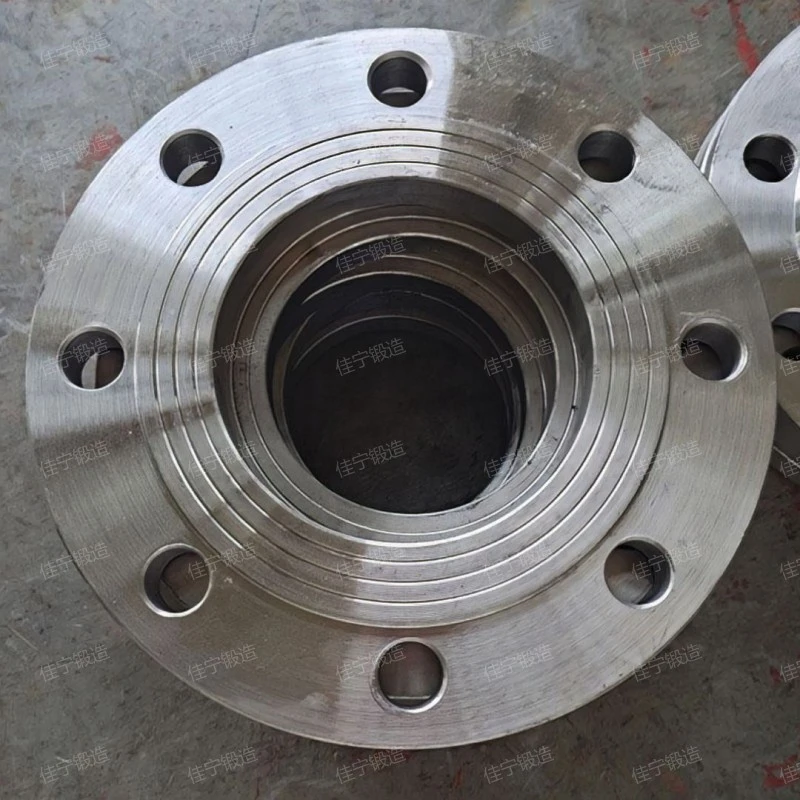

5、Q355E alloy forgings HD real shot

High-definition pictures at a glance, beautifully designed atmosphere, stylish, extraordinary temperament, for your visit.。

Q355E alloy forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Brief introduction of Jianing forging

Jianing is a strong and professional Q355E alloy forgings manufacturer, with advanced Q355E alloy forgings production technology and rich production experience. It will not only provide users with Q355E alloy forgings with Save raw materials, but also provide users with complete pre-sales, in-sales and after-sales services for the benefit of users. Welcome new and old users to visit and buy.。

Jianing forging

Q355E alloy forgingsthe product looks atmospheric.,is a workpiece or blank obtained by forging and deforming a metal blank.,the advantage is After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Q355E alloy forgings can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

Related recommendation

-

What is a Flat plate flat welded pipe flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Forged parts of transmission ring? Introduction to the principle of forging structure

2025-5-26 -

Introduction to Forged steel flat welding flange plate and flange structure principle

2025-5-26 -

Introduction to Ship shaft free forging and forging structure principle

2025-5-26 -

What is a Lining ring flat flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a High chromium bearing free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to 40CrNiMoA forging and forging working principle

2025-5-26 -

Introduction to Pancake type forgings and forging advantages and features

2025-5-26 -

Introduction to Convex sealing flat welding flange and flange working principle

2025-5-26 -

Introduction to Thin walled flat welded flange cover, flange specifications, model parameters

2025-5-26