Introduction to Forged steel flat welding flange plate and flange structure principle

Forged steel flat welding flange plateis a key connecting and sealing component.,the main features are corrosion-resistant, corrosion-resistant, High reliability, Long service life and high-temperature resistance,it is widely used in Shipbuilding industry, Air conditioning and refrigeration, petrify, device attachment and petrify,modern technology。

1、Brief introduction of Forged steel flat welding flange plate

Forged steel flat welding flange plateflange used on the inlet and outlet of equipment, used for the connection between two equipment.,The two flanges are tightly connected by bolts and other fasteners to form a firm mechanical connection, thus ensuring the stable connection between the pipeline and the equipment.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.、The two flanges are tightly connected by bolts and other fasteners to form a firm mechanical connection, thus ensuring the stable connection between the pipeline and the equipment.、The structural design makes it have strong bearing capacity and can adapt to the needs of high-pressure working environment. Excellent performance in pipeline connection of high temperature, high pressure and corrosive media, ensuring long-term stable operation of pipeline system.、The materials are varied, including carbon steel, stainless steel, alloy steel, etc. The appropriate materials can be selected according to the nature of the medium and working conditions to ensure the stability and corrosion resistance of the flange in different environments.,Widely used in Pipe connection, device attachment, seal, support and connect。

Forged steel flat welding flange plate

2、Forged steel flat welding flange plate video detail

You can buy Forged steel flat welding flange plate according to your needs and show you product videos.。

Forged steel flat welding flange plate

As you can see from the live video.,Shanxi jianing forging co., ltd is a popular Forged steel flat welding flange plate。

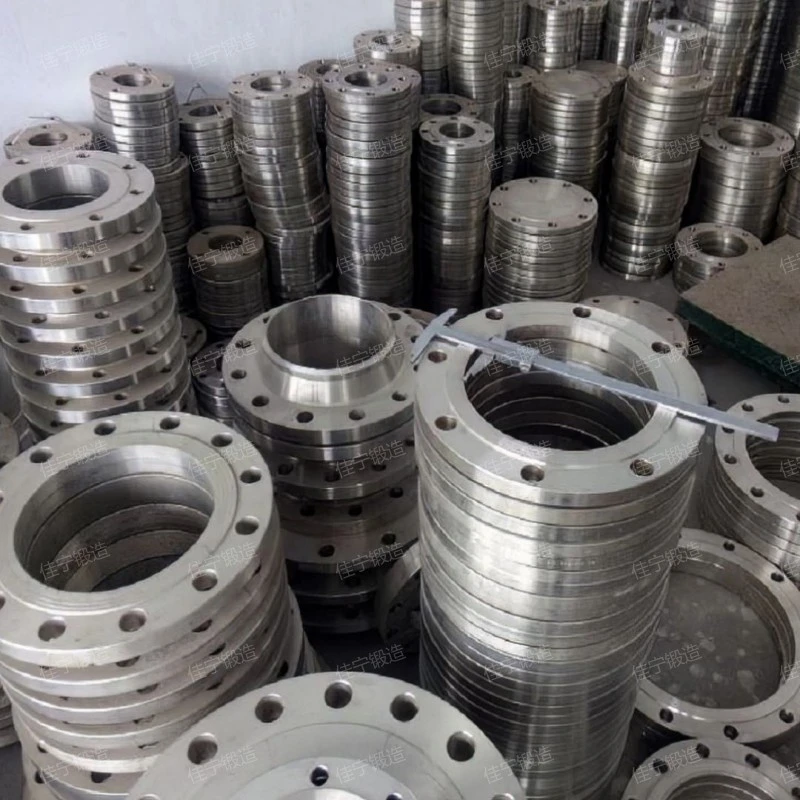

3、Forged steel flat welding flange plate display

The Forged steel flat welding flange plate has been upgraded, and the beauty of details is appreciated.。

Forged steel flat welding flange plate

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Forged steel flat welding flange plate application

Forged steel flat welding flange plates have the following purposes.

- device attachment

- Convenient disassembly

- device attachment

- connect

- Convenient disassembly

Connect all kinds of equipment and machinery, such as engines, pumps, compressors, heat exchangers, air conditioning equipment, etc.

The disassembly of the Forged steel flat welding flange plate is simple and convenient, and it is suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain.

Connect all kinds of equipment and machinery, such as engines, pumps, compressors, heat exchangers, air conditioning equipment, etc.

Forged steel flat welding flange plate can closely connect different pipelines, valves, pumps and containers to form a complete fluid conveying system.

The disassembly of the Forged steel flat welding flange plate is simple and convenient, and it is suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, which is convenient for maintenance personnel to maintain.

Forged steel flat welding flange plate

5、How much is the Forged steel flat welding flange plate?

The Forged steel flat welding flange plate price is introduced as follows:

- Parameter size

- Cost input

- technology

- market factors

- raw material

Specifications and models have a great influence on the price of Forged steel flat welding flange plate, so different specifications and models have different selling prices. Customers can reasonably select product specifications and models according to their own needs, so that products can meet their own required standards in terms of specifications and prices.

A Forged steel flat welding flange plate needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

The Forged steel flat welding flange plate market is always a fluctuating variable value. When the demand for this product in the market is far greater than the supply, the product price will be higher. On the other hand, when the market demand is much less than the supply, manufacturers are eager to sell their products and lower their prices appropriately.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Forged steel flat welding flange plate

6、Jianing service

The stable development of a manufacturer depends not only on product quality, but also on after-sales. Therefore, besides paying attention to product quality and price, the after-sales service of the manufacturer also plays a very important role in the future product application. Jianing forging provides "housekeeping" after-sales service, which is more intimate.。

Jianing

Forged steel flat welding flange plateGood stability,corrosion-resistant,High reliability,Good stability,high-temperature resistance,Simple and convenient disassembly, suitable for equipment and pipelines that need to be cleaned, overhauled or replaced frequently, convenient for maintenance personnel to maintain, and reducing downtime and maintenance cost.、The design of the connection takes into account the factors such as disassembly, cleaning, overhaul and replacement, and has good operability, which reduces the difficulty and cost of installation.、Based on the principle of surface sealing, the uneven parts on the sealing surface are filled with gaskets to realize effective sealing, prevent fluid leakage and ensure safe and stable operation in the production process.、The manufacturing cost is relatively low, and the assembly is simple through fixing methods such as screws or nuts, so that the production efficiency is improved and the production cost is reduced.、Suitable connection methods can be selected according to different requirements, such as threaded connection and welding connection, so as to adapt to different working environments and technological requirements.,It has a wide range of uses, and is often used indevice attachment,Convenient disassembly,seal,support,Pipe connection and so on。

Related recommendation

-

What is a Wind power column flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Cr12Mo1V1 free forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Die steel wheel and wheel advantages and features

2025-5-26 -

Introduction to Blind hole sleeve free forging and forging advantages and features

2025-5-26 -

What is a Integral threaded connection flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Pressure vessel tube plate, advantages, characteristics and principles of tube sheet

2025-5-26 -

What is a Type II pressure vessel forgings? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Wind Power Foundation Tour Plate and flange structure principle

2025-5-26 -

What is a Stainless steel concave flat welding flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to Hollow ring forged parts and forging advantages and features

2025-5-26