Introduction to Thickened tube plate, how much is the price of the tube sheet?

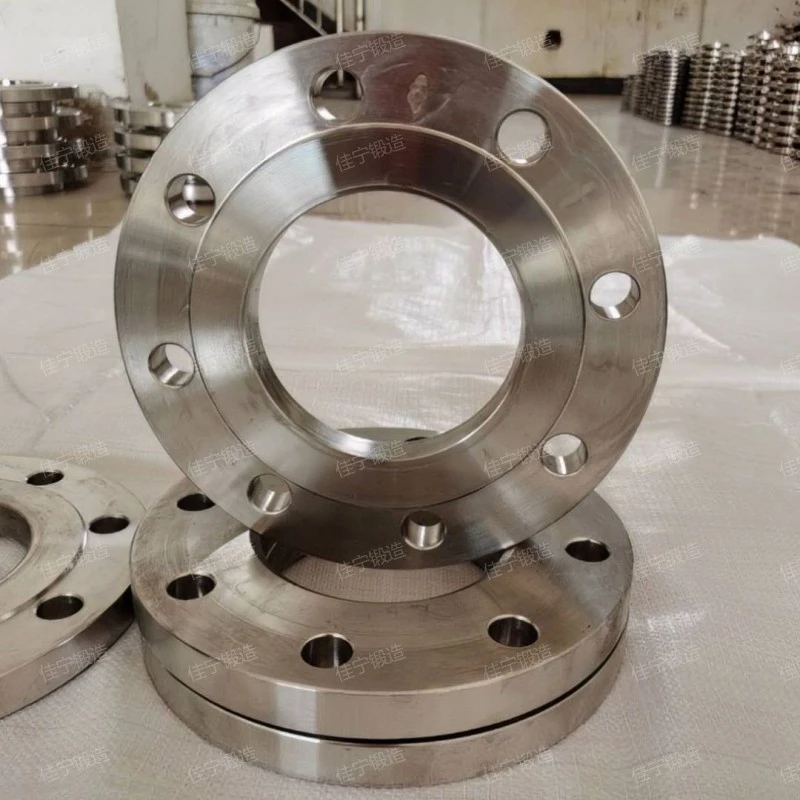

Thickened tube plateIt is a kind of fitting with specific holes drilled on circular steel plate, which are slightly larger than the outer diameter of the pipe to be penetrated.,is a popular Thickened tube plate,features include Good thermal conductivity, Strong rigidity, corrosion-resistant, High strength and rigidity and corrosion resistance,usually used in steam turbine, boiler, pressure vessel, Large central air conditioner, Large central air conditioner and other fields,is based on Jianing forging is a kind of Thickened tube plate manufactured by Jianing。

1、Brief introduction of Thickened tube plate

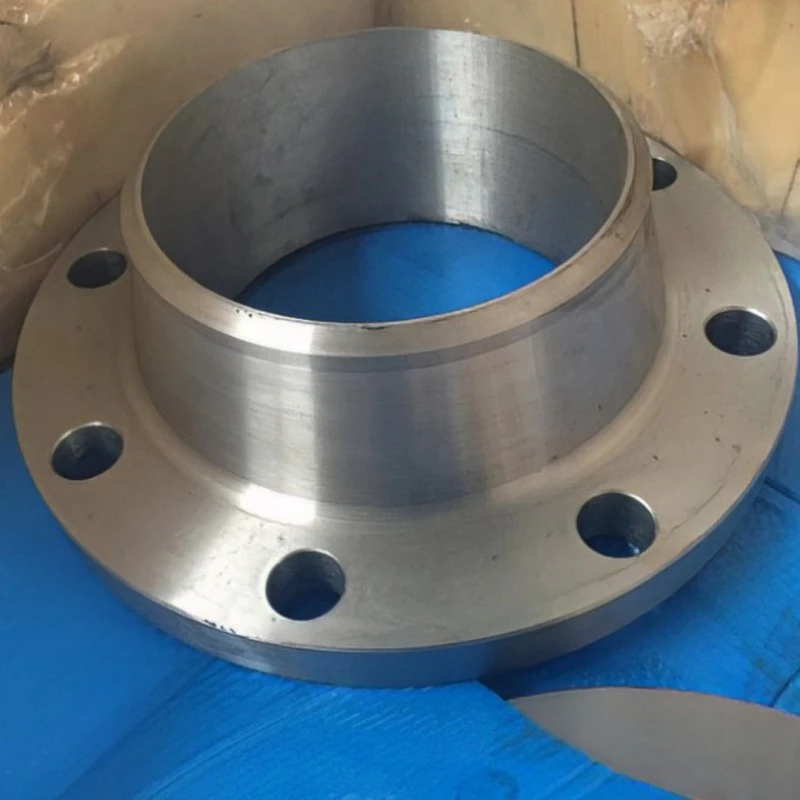

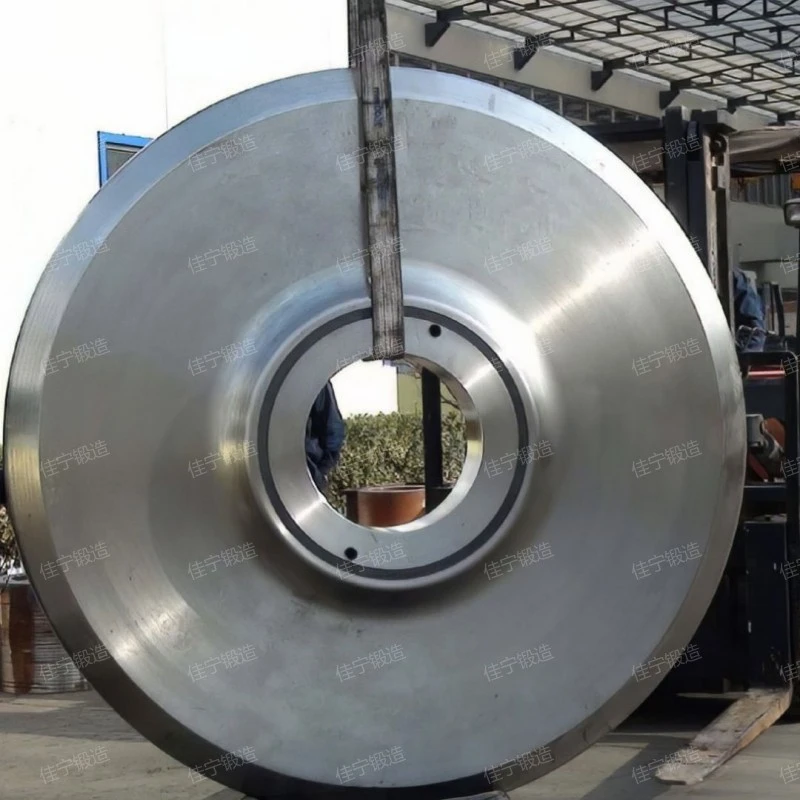

Thickened tube plateA hole slightly larger than the outer diameter of the pipe is drilled on the circular steel plate for fixing the pipe and the round steel fittings for sealing the medium. It is usually installed in a heat exchanger, and the pipe is penetrated and welded and fixed, thus playing the role of support and sealing. [Product Name] The machining accuracy, especially the distance between holes, the tolerance of pipe diameter, verticality and smoothness, has an important influence on the assembly and performance of chemical equipment.,the advantage is The contact surface with the tubes is the main channel for heat transfer. Through the design and optimization of the Thickened tube plate, the heat transfer efficiency of the heat exchanger can be improved and the energy consumption can be reduced. This is particularly important for industrial processes that require efficient heat exchange.、According to the different use environment, the Thickened tube plate can be made of corrosion-resistant materials to cope with various harsh working conditions.、The machining accuracy has been significantly improved. High-precision machining ensures the close fit and efficient sealing between the Thickened tube plate and the tube.、Structural design usually takes into account the convenience of maintenance. For example, some Thickened tube plates are connected by flanges, which is convenient for disassembly and maintenance.、It is often made of metal, which has strong rigidity and bearing capacity.。

Thickened tube plate

2、Thickened tube plate performance advantage

The advantages of Thickened tube plate are as follows:

- Strong corrosion resistance

- Adaptability and corrosion resistance

- High heat conduction efficiency

- Excellent thermal conductivity

- Easy to maintain and repair.

Depending on the use environment, the Thickened tube plate can be made of different materials, such as stainless steel, titanium alloy and other corrosion-resistant materials. This enables the Thickened tube plate to adapt to various harsh working conditions and prolongs the service life of the equipment.

Thickened tube plates can be made of different materials and thicknesses according to different use environments and requirements to meet different pressure, temperature and corrosion conditions. This enables the Thickened tube plate to adapt to various harsh working conditions and prolongs the service life of the equipment.

The contact surface between the Thickened tube plate and the tube is the main channel for heat transfer. Through the design and optimization of the Thickened tube plate, the heat transfer efficiency of the heat exchanger can be improved and the energy consumption can be reduced. This is especially important for industrial processes that require efficient heat exchange.

The metal material makes the Thickened tube plate have good heat conduction performance, which is helpful for heat transfer in the heat exchanger.

The structural design of Thickened tube plates usually takes into account the convenience of maintenance. For example, some Thickened tube plates are connected by flanges, which is convenient for disassembling and replacing pipes, thus reducing the maintenance cost and difficulty.

Thickened tube plate

3、Video analysis of Thickened tube plate

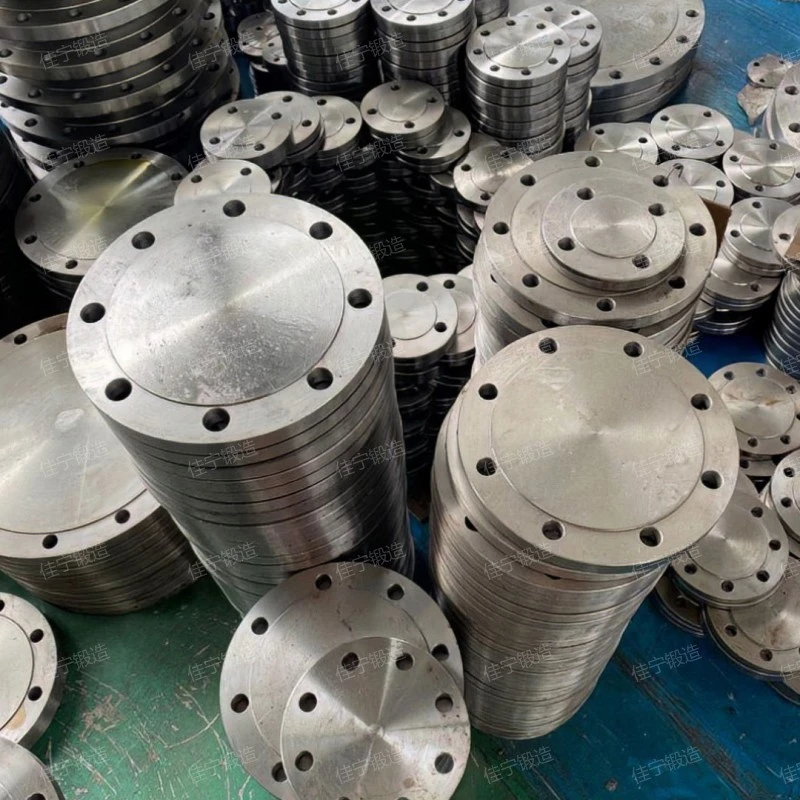

The following is the live video of Thickened tube plate designed and produced by Jianing forging for users, from which we can see the the advantage is The production adopts many advanced technologies, such as centrifugal casting and numerical control drilling machine, which improve the quality and performance of the Thickened tube plate.、As a key structural part in the equipment, it mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.、Can be customized according to the actual working conditions and fluid characteristics to meet the needs of different customers. This flexibility makes Thickened tube plates widely used in various industrial equipment.、As one of the skeletons of heat exchangers and other equipment, it is responsible for supporting and fixing the tubes to ensure that they will not be loose or deformed due to fluid impact during work. This stability is very important for the long-term operation of equipment.、The metal material makes the Thickened tube plate have good heat conduction performance, which is helpful for heat transfer in the heat exchanger. of Jianingproduction-manufacturing的Thickened tube plate.。

Thickened tube plate

As you can see from the live video.,Jianing forging widely used in pressure vessel, steam turbine, boiler, tubular exchanger, steam turbine and other fields。

4、Thickened tube plate characteristics

Thickened tube platethe main features are Strong rigidity, corrosion-resistant, corrosion resistance, Good thermal conductivity and High machining accuracy,is a popular Thickened tube plate,the product looks beautiful.,it is an ideal choice for customers to buy Thickened tube plate。

Thickened tube plate

5、Introduction of advantages of Thickened tube plate

Thickened tube plates have the following advantages.

- Convenient maintenance

- Sealing and leakage prevention

- Sealing and leakage prevention

- Easy to maintain and repair.

- Support and fixation

The structural design of Thickened tube plates usually takes into account the convenience of maintenance. For example, some Thickened tube plates are connected by flanges, which is convenient for disassembly and maintenance.

Through precise machining and assembly, the Thickened tube plate forms a close fit with the pipe, thus effectively sealing the fluid medium. This sealing function prevents fluid from leaking to the outside of the equipment, ensures the normal operation and safety of the equipment, and also avoids resource waste and environmental pollution.

Through precise machining and assembly, the Thickened tube plate forms a close fit with the pipe, thus effectively sealing the fluid medium. This sealing function prevents fluid from leaking to the outside of the equipment, ensures the normal operation and safety of the equipment, and also avoids resource waste and environmental pollution.

The structural design of Thickened tube plates usually takes into account the convenience of maintenance. For example, some Thickened tube plates are connected by flanges, which is convenient for disassembling and replacing pipes, thus reducing the maintenance cost and difficulty.

As a key structural part in the equipment, the Thickened tube plate mainly plays the role of supporting and fixing the tubes (or pipes). It ensures that the pipe will not be loosened, displaced or deformed due to fluid impact, vibration or other external forces during the operation of the equipment.

Thickened tube plate

6、Thickened tube plate price consultation

The Thickened tube plate price is introduced as follows:

- market competition

- regional difference

- Manufacturer scale

- brand

- region

Market supply and demand is the inevitable law of market development, with more market supply, less demand and lower product prices; The market supply is small, and people's demand is large. "Things are scarce and expensive", the product price will increase accordingly, and the price of Jianing Thickened tube plate will also conform to this market law.

Jianing forging has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Thickened tube plate.

Jianing's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

Different brands of products in the same series have more or less differences in product prices, and different brands of Thickened tube plate have more or less differences in price.

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

Thickened tube plate

Thickened tube plateis a Thickened tube plate,Mainly used forEasy to maintain and repair.,Easy to maintain and repair.,Improve heat transfer efficiency,Support and fixation andSealing and leakage prevention。

Related recommendation

-

What is a Plate type flat welded steel pipe flange? Introduction to the principle of flange structure

2025-5-26 -

What is a Square flat welding flange ring? Introduction to the principle of flange structure

2025-5-26 -

煤气风机轴锻件

2024-12-10 -

Introduction to Electric shaft forging parts and forging structure principle

2025-5-26 -

What is a 35SiMn forged parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to Variable diameter double-sided flange cover and flange working principle

2025-5-26 -

Introduction to Flat plate flat welded pipe flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to adapter flange and flange advantages and features

2025-5-26 -

What is a Welding special-shaped flange ring? Introduction to the Working Principle of flange

2025-5-26 -

What is a 20CrMnMo forging? forging specifications, models, and parameters

2025-5-26