Introduction to Electric shaft forging parts and forging structure principle

Electric shaft forging partsthe forging machine is used to exert pressure on the blank.,the main features are Good mechanical properties, Save raw materials, Can bear large impact force or heavy load., Good mechanical properties and high-intensity。The following is to introduce the Electric shaft forging parts:

1、Brief introduction of Electric shaft forging parts

Electric shaft forging partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the product looks beautiful.,After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Electric shaft forging parts can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Electric shaft forging parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it has been widely used in construction machinery, manufacturing industry, construction machinery, war industry, power and other industries,it is an ideal choice for customers to buy Electric shaft forging parts。

Electric shaft forging parts

2、Video analysis of Electric shaft forging parts

The following is the live video of Electric shaft forging parts designed and produced by Jianing for users, from which we can see the After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal. of JianingProduction and processing的Electric shaft forging parts.。

Electric shaft forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used in shipping, pressure vessel, metallurgy, energy and manufacturing industry。

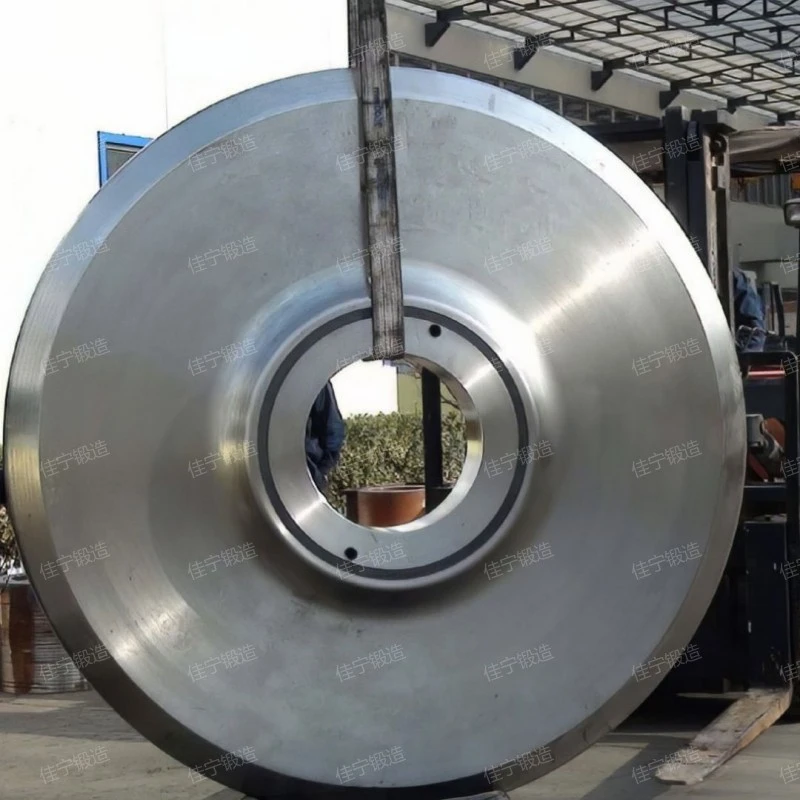

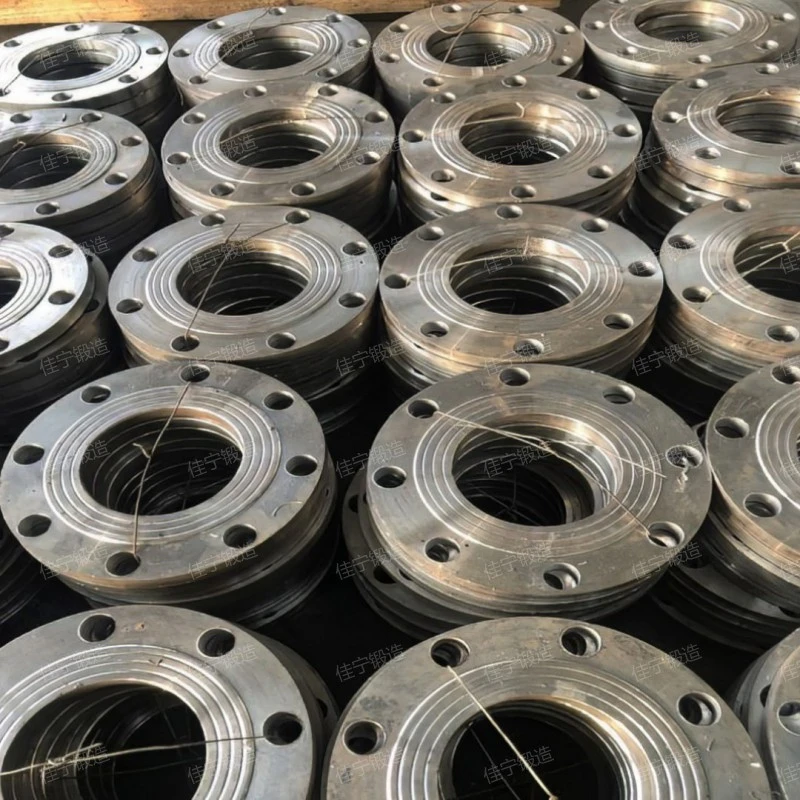

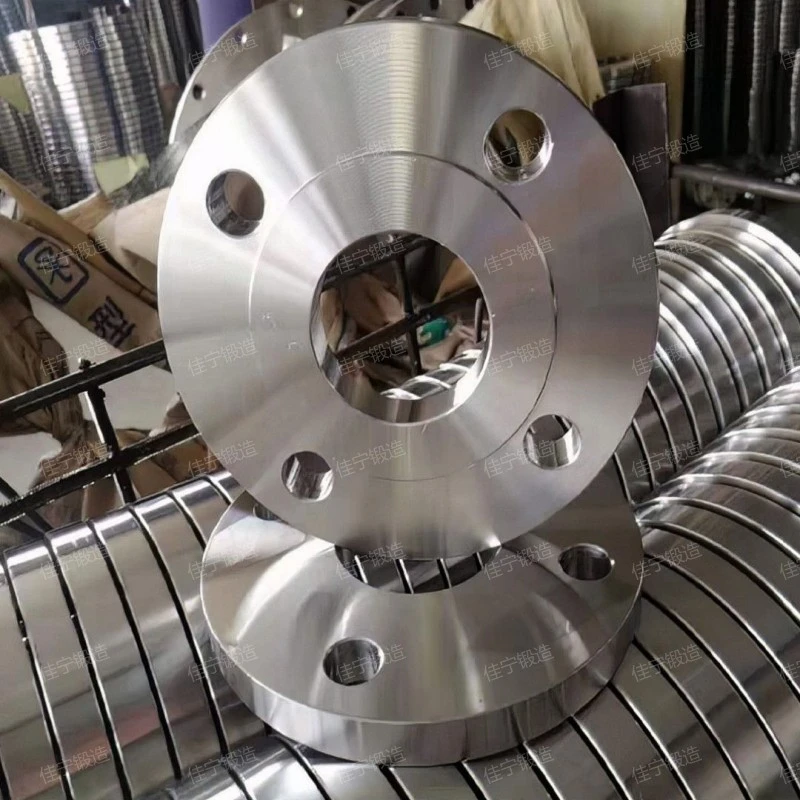

3、Electric shaft forging parts HD real shot

High-definition pictures of Electric shaft forging parts of different specifications and models,the product looks beautiful., reliable in quality and trustworthy.。

Electric shaft forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Electric shaft forging parts video

You can buy Electric shaft forging parts according to your needs and show you Electric shaft forging parts videos.。

Electric shaft forging parts

As you can see from the live video.,Jianing forging is a common Electric shaft forging parts。

5、Electric shaft forging parts characteristics

Electric shaft forging partsGood anti-fatigue performance,high tenacity,high-precision,High production efficiency,Great forging flexibility,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Electric shaft forging parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

Electric shaft forging parts

6、Why choose Jianing?

Choosing a suitable Electric shaft forging parts manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Electric shaft forging parts products that meet the demand and have good cost performance.。

Jianing forging

Electric shaft forging partsthe advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Electric shaft forging parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks atmospheric.。

Related recommendation

-

What is a Harvester wheel forgings? Introduction to the principle of wheel structure

2025-5-26 -

Introduction to PL flat welding flange cover, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Groove flat welding flange ring, flange advantages, characteristics and principles

2025-5-26 -

What is a Clamp the blind plate? How much is the price of the blind plate?

2025-5-26 -

Introduction to 20CrNiMo free forging, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Split threaded flange ring? Introduction to the principle of flange structure

2025-5-26 -

Introduction to A105 Carbon Steel Free Forging, forging advantages, characteristics and principles

2025-5-26 -

What is a Irregular thread flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Concave panel flat welding flange cover and flange structure principle

2025-5-26 -

Introduction to Gouzao flange and flange working principle

2025-5-26