What is a Four hole gear forgings? Introduction to the advantages and characteristics of gear functions

Four hole gear forgingsis a mechanical element made by forging process, with teeth on its rim, which can cooperate with other Four hole gear forgingss or racks to realize the transmission of power and movement.。The following is to introduce the Four hole gear forgings:

1、Brief introduction of Four hole gear forgings

Four hole gear forgingsis a mechanical element made by forging process, with teeth on its rim, which can cooperate with other Four hole gear forgingss or racks to realize the transmission of power and movement.,is a popular Four hole gear forgings,it has the characteristics of The tooth shape accuracy is high., Good wear resistance, Uniform material, Environmental protection advantage and High hardness,low in price,reliable quality。

Four hole gear forgings

2、Introduction of advantages of Four hole gear forgings

The advantages of Four hole gear forgings are as follows:

- Good wear resistance

- Strong bearing capacity

- High precision

- High strength and toughness

- Improve production efficiency and material utilization rate

The application of alloy steel material and heat treatment technology makes the Four hole gear forgings surface hard and wear resistant.

After the forging process, the internal structure of the Four hole gear forgings is compact, and there are no defects such as porosity and slag inclusion, so the bearing capacity is strong.

Forging process can ensure that the size accuracy and shape accuracy of the Four hole gear forgings reach a high level.

The Four hole gear forgings is manufactured by forging process, and the metal material undergoes plastic deformation at high temperature and high pressure, which eliminates internal defects such as pores and slag inclusion, and makes the material structure more dense. This compact structure makes the Four hole gear forgings have higher strength and toughness, can bear greater load and impact, and improves the durability and reliability of the Four hole gear forgings.

Forging process can usually form multiple Four hole gear forgingss at one time, and there are fewer subsequent processing steps, thus improving production efficiency. At the same time, due to the high utilization rate of materials in the forging process, the waste of materials is reduced and the production cost is reduced.

Four hole gear forgings

3、Four hole gear forgings characteristics

Four hole gear forgingsHigh strength,High shape accuracy,Can continuously mesh to transmit motion and power.,The rim is toothed.,Wide range of applications,the product looks beautiful.,the product looks atmospheric.。

Four hole gear forgings

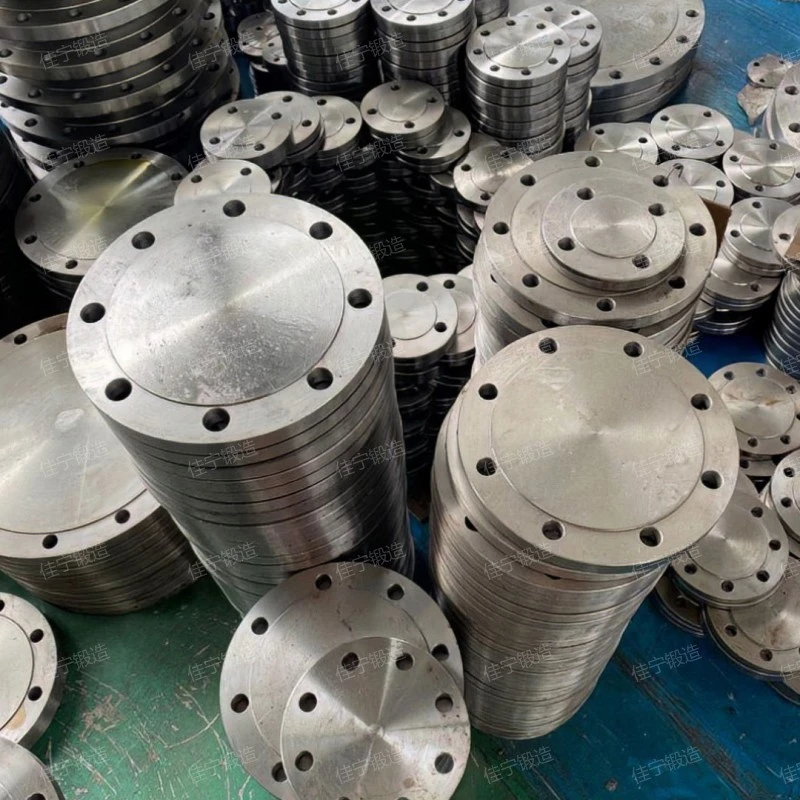

4、Four hole gear forgings HD picture

Excellent material selection,the product looks beautiful., trustworthy, panoramic shooting, helpful for customer reference.。

Four hole gear forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Four hole gear forgings use

Four hole gear forgingsMainly used forTransmit motion and power.,Improve transmission accuracy and efficiency,Bear load and impact,Transmit motion and power. andImprove transmission accuracy and efficiency,it is an ideal choice for customers to buy Four hole gear forgings。

Four hole gear forgings

6、Four hole gear forgings price consultation

The Four hole gear forgings price is introduced as follows:

- product configuration

- Self quality

- technology content

- select a qualified person

- company strength

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. Jianing forging has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

The Four hole gear forgings is made of high-quality materials, and the cost of the product is high, so the price of the product will also rise. Jianing has always adhered to high quality in the construction of Four hole gear forgings and won the trust of customers.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

The quality of material selection is one of the main factors that directly affect the Four hole gear forgings. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

Four hole gear forgings

Four hole gear forgingsis an important part of transmission mechanism, and its rim is designed with teeth, which can continuously mesh to transmit motion and power.,it is widely used inautomobile making,mining machinery,automobile making,mining machinery,petrochemical industry and other industries。

Related recommendation

-

What is a DN2000 flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Flat welded stainless steel flange ring with raised surface plate and flange advantages and features

2025-5-26 -

高速轴锻件

2024-12-10 -

Introduction to Stainless steel bearing forged parts, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Horizontal tube plate flange and tube sheet working principle

2025-5-26 -

Introduction to Card sleeve internal thread flange ring and flange advantages and features

2025-5-26 -

Introduction to SO variable diameter flange ring and flange working principle

2025-5-26 -

What is a Cr12MoV ring forging? Introduction to the principle of forging structure

2025-5-26 -

底法兰

2024-12-10 -

What is a Hydraulic cylinder bottom forging parts? Introduction to the principle of forging structure

2025-5-26