What is a Hydraulic cylinder bottom forging parts? Introduction to the principle of forging structure

Hydraulic cylinder bottom forging partsrefers to the workpiece or blank obtained by forging metal blank.,is a Hydraulic cylinder bottom forging parts,it is widely used inmanufacturing industry,metallurgy,pressure vessel,shipping,energy and other industries,Good anti-fatigue performance,Save raw materials,High productivity,Good mechanical properties,Great forging flexibility,is an advanced Hydraulic cylinder bottom forging parts developed by our company in combination with the actual situation of the industry。The following is to introduce the Hydraulic cylinder bottom forging parts:

1、Brief introduction of Hydraulic cylinder bottom forging parts

Hydraulic cylinder bottom forging partsthe forging machine is used to exert pressure on the blank.,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Hydraulic cylinder bottom forging parts.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Hydraulic cylinder bottom forging parts can be improved.,the product looks beautiful.,is a kind of high quality and low price Hydraulic cylinder bottom forging parts,it can be used in war industry, construction machinery, automobile, power, automobile and other industries。

Hydraulic cylinder bottom forging parts

2、Introduction of advantages of Hydraulic cylinder bottom forging parts

Hydraulic cylinder bottom forging partss have the following advantages.

- High degree of automation

- high tenacity

- Eliminate internal defects

- Improve material utilization rate

- high-intensity

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The fiber structure of the Hydraulic cylinder bottom forging parts is reasonably distributed, which improves the toughness of the material and enables the Hydraulic cylinder bottom forging parts to bear greater impact force and alternating stress.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Hydraulic cylinder bottom forging parts.

In the process of Hydraulic cylinder bottom forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Hydraulic cylinder bottom forging parts

3、Video analysis of Hydraulic cylinder bottom forging parts

Speak directly with facts on the spot。

Hydraulic cylinder bottom forging parts

As you can see from the live video.,Jianing forging refers to the workpiece or blank obtained by forging metal blank.。

4、Introduction of Hydraulic cylinder bottom forging parts characteristics

Hydraulic cylinder bottom forging partsthe main features are high-precision, high tenacity, Can bear large impact force or heavy load., Light weight and high-intensity,has been favored by more and more customers.。

Hydraulic cylinder bottom forging parts

5、Hydraulic cylinder bottom forging parts price advantage

The Hydraulic cylinder bottom forging parts price is introduced as follows:

- company strength

- product configuration

- market competition

- Brand strength

- regional difference

Our factory is a direct selling manufacturer of Hydraulic cylinder bottom forging parts, with independent production and processing facilities, few circulation links and low circulation cost.

Products of the same style, different configurations, the product price is definitely different, therefore, the Hydraulic cylinder bottom forging parts price is affected by the configuration, and the price varies.

Generally, when the supply of Hydraulic cylinder bottom forging parts exceeds the demand in the market, the product price will naturally decrease, on the contrary, the product price will increase.

At present, there are various brands of Hydraulic cylinder bottom forging parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Hydraulic cylinder bottom forging parts are different.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

Hydraulic cylinder bottom forging parts

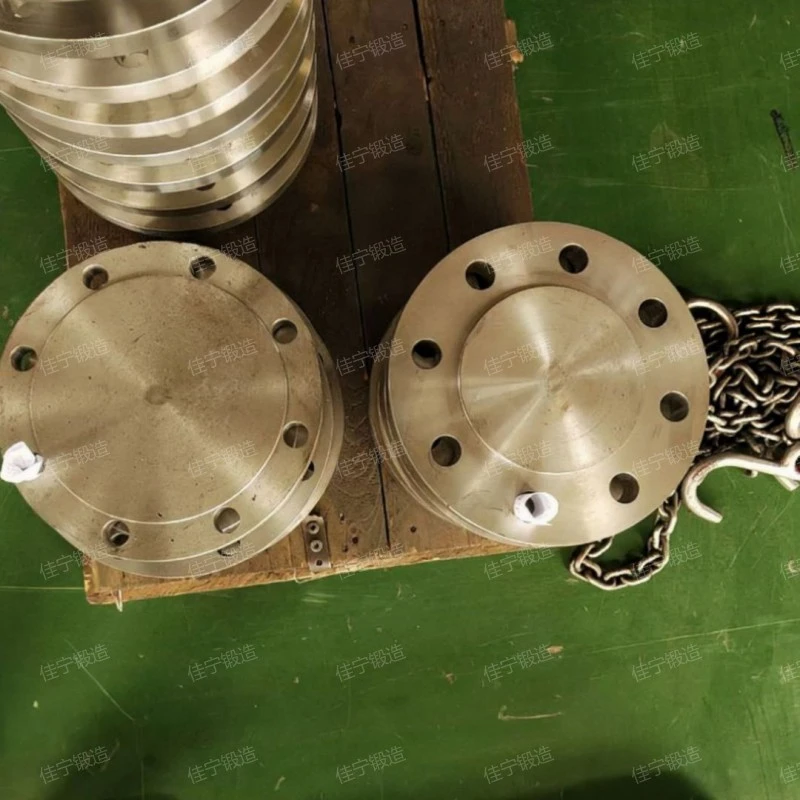

6、High-definition picture display of Jianing workshop

The finished products of the Hydraulic cylinder bottom forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing forging

The finished products of the Hydraulic cylinder bottom forging parts factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Hydraulic cylinder bottom forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks atmospheric.,it has the characteristics of High production efficiency, Good anti-fatigue performance, high-precision, Light weight and High production efficiency。

Related recommendation

-

What is a 30Cr free forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Irregular forged parts, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to 1Cr5Mo welded flange plate, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Convex concave surface welding flange plate, flange specifications, model parameters

2025-5-26 -

Introduction to Special stainless steel free forging, forging specifications, model parameters

2025-5-26 -

Introduction to Disc-shaped forgings, forging specifications, model parameters

2025-5-26 -

Introduction to RF ring gear forgings, advantages, characteristics and principles of ring gear

2025-5-26 -

Introduction to Stainless steel cake forging parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Manhole blind flange and blind plate structure principle

2025-5-26 -

What is a Alloy steel pressure vessel flange? Introduction to the principle of flange structure

2025-5-26