Introduction to Carbon steel wheel forgings, introduction to wheel function advantages and characteristics

Carbon steel wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Carbon steel wheel forgings can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.,is a kind of Carbon steel wheel forgings manufactured by Jianing forging。

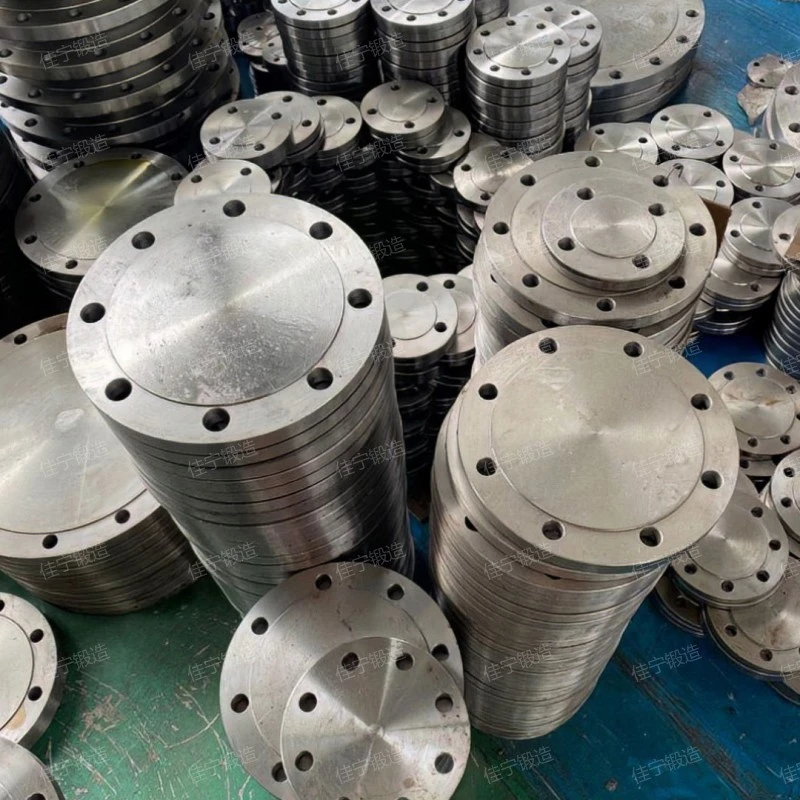

1、Brief introduction of Carbon steel wheel forgings

Carbon steel wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Carbon steel wheel forgingss can be divided into cold forging, warm forging and hot forging according to the temperature of the blank during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a temperature higher than the recrystallization temperature of the metal blank.,is a popular Carbon steel wheel forgings,Cheap and high quality。

Carbon steel wheel forgings

2、Carbon steel wheel forgings introduction video

The following is the live video of Carbon steel wheel forgings designed and produced by Jianing forging for users, from which we can see the the advantage is It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Carbon steel wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Carbon steel wheel forgings have excellent mechanical properties and wear resistance. of Jianingproduce的Carbon steel wheel forgings.。

Carbon steel wheel forgings

As you can see from the live video.,Shanxi jianing forging co., ltd the main features are Good physical properties, individualized design, High strength, Excellent heat dissipation performance and High strength。

3、Carbon steel wheel forgings characteristics

Carbon steel wheel forgingsfeatures include individualized design, Superior mechanical properties, Good physical properties, Strong corrosion resistance and Lightweight design,the product looks atmospheric.,support customization。

Carbon steel wheel forgings

4、Carbon steel wheel forgings advantage

The advantages of Carbon steel wheel forgings are as follows:

- Good economy

- Good anti-fatigue performance

- Exquisite appearance

- High strength

- Lightweight design

Its excellent mechanical properties, lightweight design and corrosion resistance can significantly reduce the operating cost and maintenance cost of equipment.

After forging, the micro defects in the Carbon steel wheel forgings are eliminated, and the structure is more uniform and dense, thus improving the fatigue resistance. This is especially important for equipment that needs to run for a long time and bear periodic loads.

In the process of processing, the Carbon steel wheel forgings has been treated with fine surface, and its appearance is exquisite and flawless, which is deeply welcomed and respected by people.

In the forging process, the plastic deformation improves the density and uniformity of the material, so it has a high strength-to-weight ratio and can resist long-term friction and wear.

Forging process can accurately control the distribution of materials, so that the Carbon steel wheel forgings can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

Carbon steel wheel forgings

5、Structural characteristics of Carbon steel wheel forgings

The Carbon steel wheel forgings has the following structure

- spoke

- hub

- hub

- wheel flange

- spoke

The part connecting the hub and the rim plays the role of supporting and transmitting load.

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

There are various structural forms, such as straight spoke, oblique spoke, spoke plate, etc., and the specific form depends on the purpose, load characteristics and lightweight requirements of the Carbon steel wheel forgings.

Carbon steel wheel forgings

6、company profile

Jianing is a strong and professional Carbon steel wheel forgings manufacturer, with advanced Carbon steel wheel forgings production technology and rich production experience. It will not only provide users with Carbon steel wheel forgings with Exquisite appearance, but also provide users with complete pre-sales, in-sales and after-sales services for the benefit of users. Welcome new and old users to visit and buy.。

Jianing forging

Carbon steel wheel forgingsIn the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Carbon steel wheel forgings have excellent mechanical properties and wear resistance.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.,is a kind of high quality and low price Carbon steel wheel forgings。

Related recommendation

-

Introduction to Flat welded flange with perforated plate, advantages, characteristics and principles of flange

2025-5-26 -

What is a Flat ring forgings? forging specifications, models, and parameters

2025-5-26 -

Introduction to Flat welded pipe flange with raised surface plate, flange specifications, model parameters

2025-5-26 -

What is a Heat resistant steel forged parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Flat welding threaded flange cover, introduction to flange advantages and characteristics

2025-5-26 -

What is a Forged parts of train axles? Introduction to the principle of forging structure

2025-5-26 -

What is a PN100 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

What is a 12Cr1Mov flat welding flange plate? Introduction to the principle of flange structure

2025-5-26 -

十字轴模锻件

2024-12-10 -

Introduction to SAE integral butt welded flange and flange working principle

2025-5-26