What is a Carbon steel wheel? Introduction to the principle of wheel structure

Carbon steel wheelis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Carbon steel wheel can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.。

1、Brief introduction of Carbon steel wheel

Carbon steel wheelthe metal blank is heated to a proper temperature, and then is plastically deformed by applying pressure on forging equipment, so as to obtain a Carbon steel wheel with a predetermined shape, size and mechanical properties.,the product looks beautiful.,is a common Carbon steel wheel,the product looks atmospheric.,it is an ideal choice for customers to buy Carbon steel wheel。

Carbon steel wheel

2、Video analysis of Carbon steel wheel

On-site aerial photography of Carbon steel wheel。

Carbon steel wheel

As you can see from the live video.,Jianing it is widely used inHeavy equipment,rolling stock,automobile,Petrochemical general,Basic parts and other industries。

3、Functional advantages of Carbon steel wheel

Carbon steel wheels have the following advantages.

- Lightweight design

- Good physical properties

- high tenacity

- High strength

- Strong corrosion resistance

Forging process can accurately control the distribution of materials, so that the Carbon steel wheel can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

During the forging process, the Carbon steel wheel formed a fine particle structure and improved its physical properties, such as toughness and fatigue strength, which made the Carbon steel wheel show excellent performance in practical application.

In the process of forging, the metal blank undergoes plastic deformation under pressure, thus improving the toughness of the material. This makes the Carbon steel wheel not easy to break when it bears impact, and enhances its durability and reliability.

In the forging process, the plastic deformation improves the density and uniformity of the material, so it has a high strength-to-weight ratio and can resist long-term friction and wear.

After proper surface treatment (such as spraying anticorrosive paint, etc.), the corrosion resistance of the Carbon steel wheel can be significantly improved. This is especially important for equipment operating in harsh environment, which can prolong the service life of Carbon steel wheels and reduce maintenance costs.

Carbon steel wheel

4、Carbon steel wheel application

Carbon steel wheelIt has a wide range of uses, and is often used inAdapt to different environments and conditions,Industrial application,load capacity,Provides stability and handling.,Provides stability and handling. and so on,the product looks beautiful.,the advantage is In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Carbon steel wheel have excellent mechanical properties and wear resistance.、It has good comprehensive mechanical properties and wear resistance, and can bear large loads and impacts.、In the process of forging, the metal streamline is retained, which makes the mechanical properties of forgings better than those of castings of the same material. In addition, the forging process can also eliminate the defects of as-cast porosity and optimize the microstructure, thus improving the service life and reliability of forgings.、This processing method can optimize the microstructure of metal, eliminate defects such as as as-cast porosity, improve the density and strength of materials, and make the Carbon steel wheel have excellent mechanical properties and wear resistance.,it is widely used in construction machinery, crane, Port machinery, automobile, Port machinery and other industries,is based on Jianing is a Carbon steel wheel newly developed by Jianing。

Carbon steel wheel

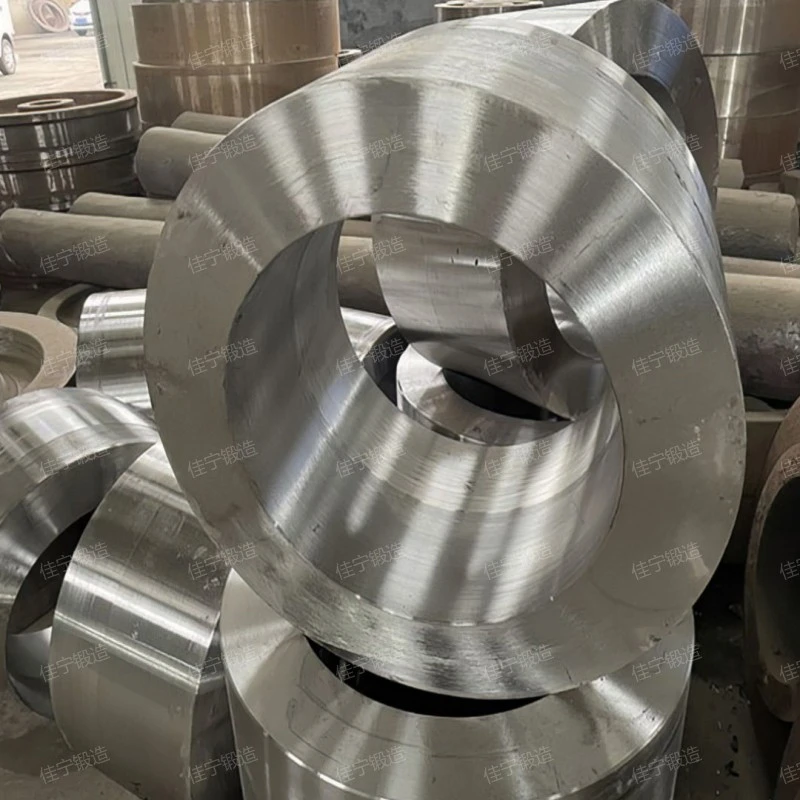

5、Carbon steel wheel HD real picture

Carbon steel wheel HD real shot, a variety of specifications and models display, for our customers to choose at will.。

Carbon steel wheel

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Carbon steel wheel price

The Carbon steel wheel price is introduced as follows:

- Configuration difference

- quality factor

- geographical position

- regional advantages

- Service factor

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. Jianing forging pays special attention to the hardware configuration of products, so Jianing Carbon steel wheel has a higher cost performance.

Quality is one of the fundamental and important factors that affect the price. Usually, the better the quality of the Carbon steel wheel, the higher its price, and the quality is mainly affected by the manufacturing process, raw material materials, workers' experience and other factors. Therefore, if customers want to buy products with better quality, they can conduct on-the-spot visits to the product manufacturers to learn more about the scale, manufacturing process and production capacity of the manufacturers, so as to comprehensively judge the quality of the products.

Different provinces and regions have different consumption levels, different market positioning and different prices.

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging Carbon steel wheel manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Carbon steel wheel price can meet the purchasing needs of customers.

Carbon steel wheel

Carbon steel wheelis a Carbon steel wheel part made by forging process.,the product looks beautiful.。

Related recommendation

-

What is a Carbon steel shaft forgings? forging specifications, models, and parameters

2025-5-26 -

Introduction to 60CrMo forging and forging working principle

2025-5-26 -

Introduction to Conical thread flange and flange working principle

2025-5-26 -

What is a Threaded movable flange ring? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Cylinder liner forging parts and forging advantages and features

2025-5-26 -

Introduction to Stainless steel flange ring, advantages, characteristics and principles of flange

2025-5-26 -

What is a Welding integral flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Non neck flat welding flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to 40Cr fan shaft forging, introduction to forging advantages and characteristics

2025-5-26 -

What is a H13 round cake free forging? How much is the price of the forging?

2025-5-26