What is a Crown wheel forgings? How much is the price of the wheel?

Crown wheel forgingsis a Crown wheel forgings part processed by forging process.。

1、Brief introduction of Crown wheel forgings

Crown wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Crown wheel forgings can be divided into cold forging, warm forging and hot forging according to the temperature of blank during processing.,It is a product series that integrates Industrial application, load capacity, Vehicle movement, Industrial application and Vehicle movement,it has the characteristics of Excellent heat dissipation performance, individualized design, Strong corrosion resistance, Excellent heat dissipation performance and Lightweight design。

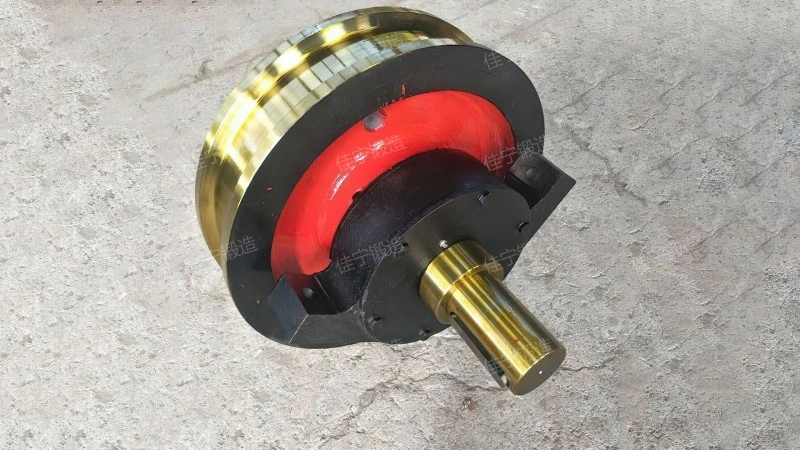

Crown wheel forgings

2、Crown wheel forgings advantage

The advantages of Crown wheel forgings are as follows:

- high tenacity

- Good economy

- Lightweight design

- Good anti-fatigue performance

- High strength

In the process of forging, the metal blank undergoes plastic deformation under pressure, thus improving the toughness of the material. This makes the Crown wheel forgings not easy to break when it bears impact, and enhances its durability and reliability.

Its excellent mechanical properties, lightweight design and corrosion resistance can significantly reduce the operating cost and maintenance cost of equipment.

Forging process can accurately control the distribution of materials, so that the Crown wheel forgings can achieve lightweight design while maintaining sufficient strength. Lightweight design is helpful to reduce the weight of the vehicle, reduce fuel consumption and improve the fuel economy of the vehicle.

After forging, the micro defects in the Crown wheel forgings are eliminated, and the structure is more uniform and dense, thus improving the fatigue resistance. This is especially important for equipment that needs to run for a long time and bear periodic loads.

In the forging process, the plastic deformation improves the density and uniformity of the material, so it has a high strength-to-weight ratio and can resist long-term friction and wear.

Crown wheel forgings

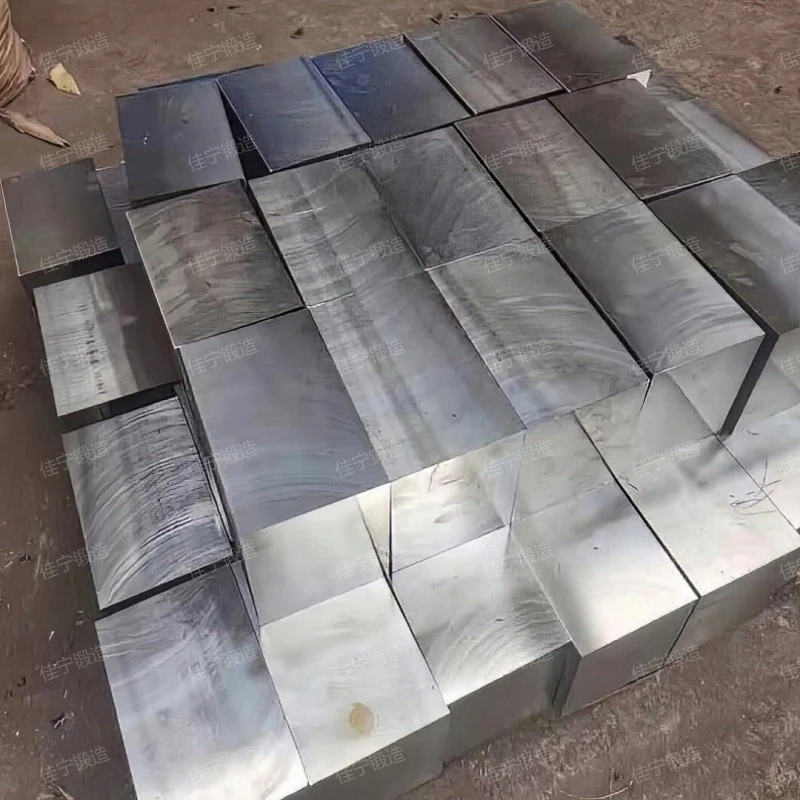

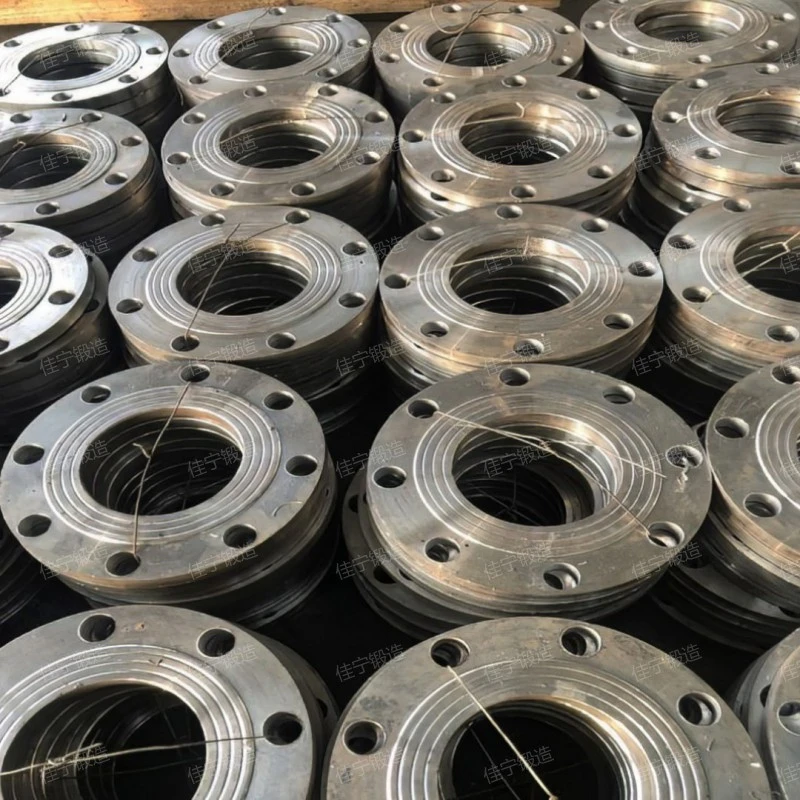

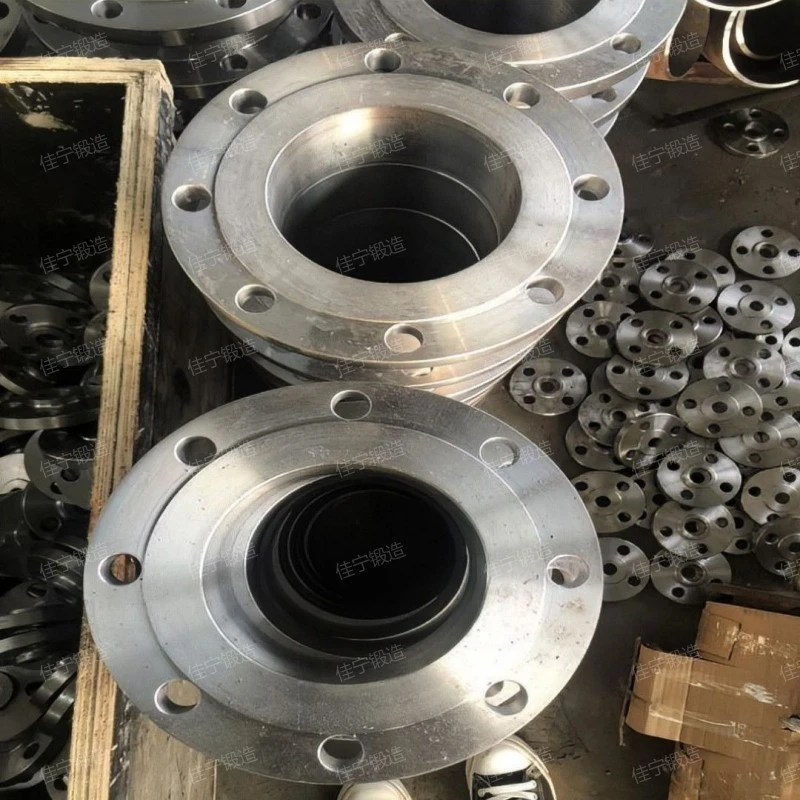

3、Crown wheel forgings customer scene picture

High-definition picture display of Crown wheel forgings, excellent material selection, reliable quality and trustworthy.。

Crown wheel forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Crown wheel forgings structure

The Crown wheel forgings structure is introduced as follows:

- hub

- spoke

- wheel flange

- spoke

- hub

Usually, mounting holes or flanges are designed for mounting bearings or directly connecting with axles to bear forces and moments from axles or transmission devices.

The part connecting the hub and the rim plays the role of supporting and transmitting load.

Bear the impact, friction and wear from the road surface, so it needs to have high strength and wear resistance.

There are various structural forms, such as straight spoke, oblique spoke, spoke plate, etc., and the specific form depends on the purpose, load characteristics and lightweight requirements of the Crown wheel forgings.

The structure is usually designed with mounting holes, flanges or keyways, etc., so as to closely cooperate with the shaft head or bearing.

Crown wheel forgings

5、Introduction of Crown wheel forgings characteristics

Crown wheel forgingsfeatures include High strength, Superior mechanical properties, Good physical properties, Strong corrosion resistance and individualized design,is a common Crown wheel forgings,the product looks atmospheric.,is carefully developed by Jianing forging combined with advanced technology。

Crown wheel forgings

Crown wheel forgingsis a workpiece or blank obtained by forging a metal blank. In the forging process, pressure is applied to the metal blank to cause plastic deformation, thus changing its mechanical properties. Crown wheel forgingss can be divided into cold forging, warm forging and hot forging according to the temperature of the blank during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a temperature higher than the recrystallization temperature of the metal blank.,widely used in Basic parts, construction machinery, automobile, Port machinery, crane and other fields。

Related recommendation

-

Introduction to Modular free forging and forging structure principle

2025-5-26 -

Introduction to Flat welding protruding flange, introduction to flange advantages and characteristics

2025-5-26 -

What is a Grooved flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a Flange ring forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Forging parts for lathe spindle? forging specifications, models, and parameters

2025-5-26 -

What is a Pump body free forging? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Pressure vessel manhole flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to National standard carbon steel forging parts, how much is the price of the forging?

2025-5-26 -

Introduction to Flat welded orifice plate flange and flange advantages and features

2025-5-26 -

Introduction to Wheel axle forgings, introduction to forging advantages and characteristics

2025-5-26