What is a Forging parts for lathe spindle? forging specifications, models, and parameters

Forging parts for lathe spindleplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it has the characteristics of Good anti-fatigue performance, High productivity, high-intensity, Save raw materials and Good mechanical properties。The following is to introduce the Forging parts for lathe spindle:

1、Brief introduction of Forging parts for lathe spindle

Forging parts for lathe spindleforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,it is widely used in pressure vessel, war industry, rail traffic, automobile and shipping,is a kind of Forging parts for lathe spindle manufactured by Jianing forging。

Forging parts for lathe spindle

2、Introduction of Forging parts for lathe spindle characteristics

Forging parts for lathe spindlefeatures include Great forging flexibility, high-precision, Light weight, High production efficiency and high tenacity,is a workpiece or blank obtained by forging and deforming a metal blank.,can be customized according to user's needs.。

Forging parts for lathe spindle

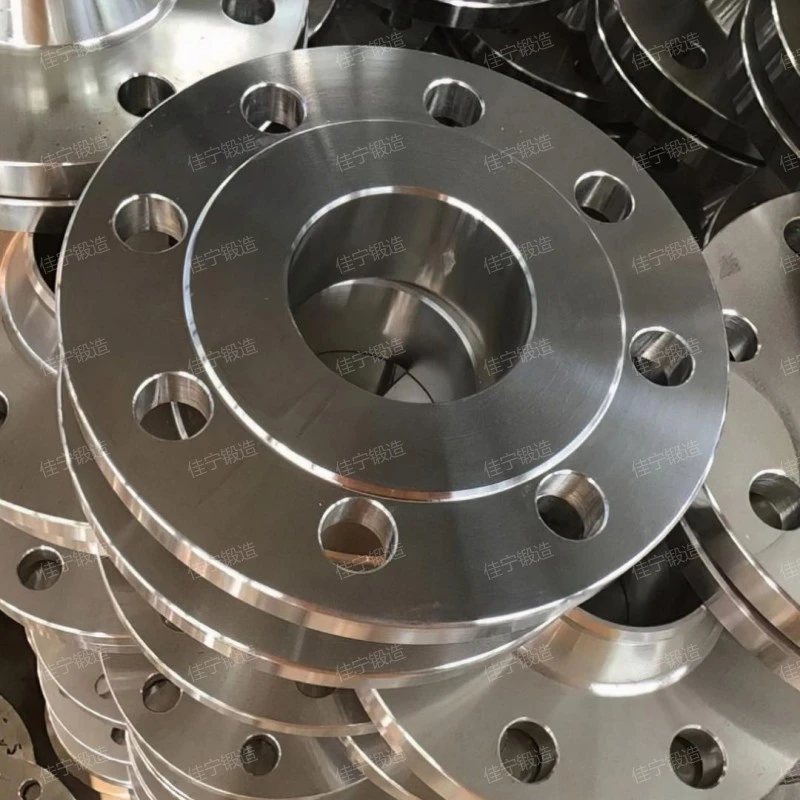

3、Forging parts for lathe spindle real shot picture

Forging parts for lathe spindle are widely used. The following is a multi-directional display diagram of Forging parts for lathe spindle, and the details are full of quality and intelligence.。

Forging parts for lathe spindle

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Forging parts for lathe spindle advantage

The advantages of Forging parts for lathe spindle are as follows:

- Good fatigue resistance.

- Improve material utilization rate

- high tenacity

- Perfect quality assurance system

- high-intensity

The particle flow inside the Forging parts for lathe spindle flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the process of Forging parts for lathe spindle production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The fiber structure of the Forging parts for lathe spindle is reasonably distributed, which improves the toughness of the material and enables the Forging parts for lathe spindle to bear greater impact force and alternating stress.

In the process of Forging parts for lathe spindle production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forging parts for lathe spindle.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging parts for lathe spindle

5、Forging parts for lathe spindle characteristics

Forging parts for lathe spindleCan bear large impact force or heavy load.,Light weight,Good anti-fatigue performance,Great forging flexibility,high-precision,it is an ideal choice for customers to buy Forging parts for lathe spindle。

Forging parts for lathe spindle

6、Forging parts for lathe spindle price concessions

The Forging parts for lathe spindle price is introduced as follows:

- Different regions

- Manufacturer's strength

- product costs

- mass discrepancy

- Configuration difference

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

Our company's expected profit value of Forging parts for lathe spindle is relatively low, and adopts the sales policy of small profits but quick turnover, so the price positioning of Forging parts for lathe spindle is relatively low.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Forging parts for lathe spindle.

The quality of the Forging parts for lathe spindle is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the Forging parts for lathe spindle price.

The difference in Forging parts for lathe spindle configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Forging parts for lathe spindle

Forging parts for lathe spindleis a kind of high quality and low price Forging parts for lathe spindle,the product looks beautiful.,refers to the workpiece or blank obtained by forging metal blank.。

Related recommendation

-

汽轮机电轴锻件

2024-12-10 -

What is a 316 butt welded flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a A105 Carbon Steel Forged Parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Ship shaft forgings, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to 9Cr2Mo forging, how much is the price of the forging?

2025-5-26 -

What is a PL steel flat welded pipe flange cover? flange specifications, models, and parameters

2025-5-26 -

What is a Variable diameter flange cover? How much is the price of the flange?

2025-5-26 -

What is a Flat welding flange cover with convex surface on the plate? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Chuck thread flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Q355C alloy forgings, forging specifications, model parameters

2025-5-26