Introduction to Suspension rod forging parts, introduction to forging advantages and characteristics

Suspension rod forging partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,modern technology。

1、Brief introduction of Suspension rod forging parts

Suspension rod forging partsrefers to the workpiece or blank obtained by forging metal blank.,it is widely used inenergy,manufacturing industry,power,rail traffic,pressure vessel and other industries,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Suspension rod forging parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,is a Suspension rod forging parts,the product looks beautiful.。

Suspension rod forging parts

2、Suspension rod forging parts characteristics

Suspension rod forging partshigh tenacity,high-intensity,High productivity,Light weight,Save raw materials,is a popular Suspension rod forging parts,the product looks atmospheric.。

Suspension rod forging parts

3、Functional advantages of Suspension rod forging parts

Suspension rod forging partss have the following advantages.

- Eliminate internal defects

- Improve material utilization rate

- Perfect quality assurance system

- High dimensional accuracy

- high-intensity

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Suspension rod forging parts.

In the process of Suspension rod forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

In the process of Suspension rod forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Suspension rod forging parts.

In the forging process of Suspension rod forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Suspension rod forging parts

4、Suspension rod forging parts video detail

Speak directly with facts on the spot。

Suspension rod forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd it has been widely used in shipping, metallurgy, energy, manufacturing industry, pressure vessel and other industries。

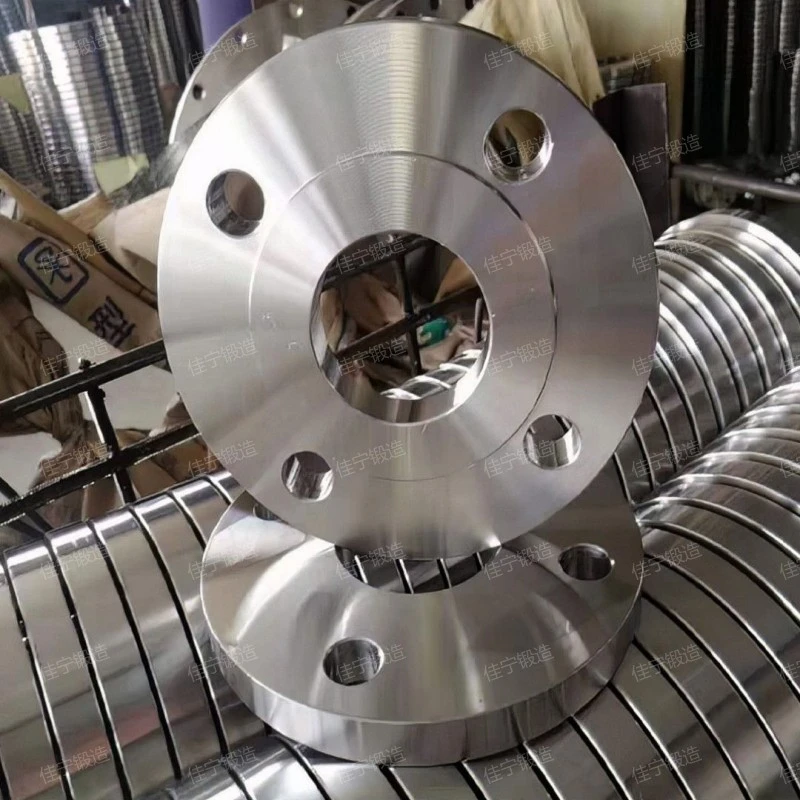

5、Suspension rod forging parts real shot picture

Overview of high-definition pictures,the product looks beautiful.。

Suspension rod forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Suspension rod forging parts quotation

The Suspension rod forging parts price is introduced as follows:

- service

- Parameter size

- type of operation

- Brand strength

- company strength

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging Suspension rod forging parts manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Suspension rod forging parts price can meet the purchasing needs of customers.

Because there are many models of each product, different customers have different requirements for product performance, and the product specifications and models that are inevitably used will be different. Different models of the same product will lead to different prices.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Suspension rod forging parts is low.

At present, there are various brands of Suspension rod forging parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Suspension rod forging parts are different.

Our factory is a direct selling manufacturer of Suspension rod forging parts, with independent production and processing facilities, few circulation links and low circulation cost.

Suspension rod forging parts

Suspension rod forging partsthe advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Suspension rod forging parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Suspension rod forging parts.、After forging, its structure and mechanical properties can be improved.,the product looks atmospheric.。

Related recommendation

-

What is a Reducing flat welding flange plate? Introduction to the Working Principle of flange

2025-5-26 -

What is a 304 stainless steel threaded flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Low temperature steel cylinder forging parts, forging specifications, model parameters

2025-5-26 -

What is a Steel pipe welded flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Steam pipeline flat welding flange cover and flange structure principle

2025-5-26 -

Introduction to 5-inch flange and flange working principle

2025-5-26 -

What is a Wind power gear ring forgings? Introduction to the principle of ring gear structure

2025-5-26 -

Introduction to Alien flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Welding protruding flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Threaded flat welding flange cover and flange working principle

2025-5-26