Introduction to Low temperature steel cylinder forging parts, forging specifications, model parameters

Low temperature steel cylinder forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Low temperature steel cylinder forging parts.、After forging, its structure and mechanical properties can be improved.,is a common Low temperature steel cylinder forging parts。

1、Brief introduction of Low temperature steel cylinder forging parts

Low temperature steel cylinder forging partsrefers to the workpiece or blank obtained by forging metal blank.,widely used inrail traffic,construction machinery,manufacturing industry,energy,metallurgy and other industries,the main features are Can bear large impact force or heavy load., Save raw materials, Great forging flexibility, high-precision and High productivity,the product looks beautiful.,be loved by our customers.。

Low temperature steel cylinder forging parts

2、Low temperature steel cylinder forging parts characteristics

Low temperature steel cylinder forging partsit has the characteristics of Light weight, Good mechanical properties, High production efficiency, Save raw materials and high tenacity,plastic deformation is made to obtain forgings with certain shapes and mechanical properties.,it is widely used inpower,shipping,pressure vessel,rail traffic,automobile and other industries。

Low temperature steel cylinder forging parts

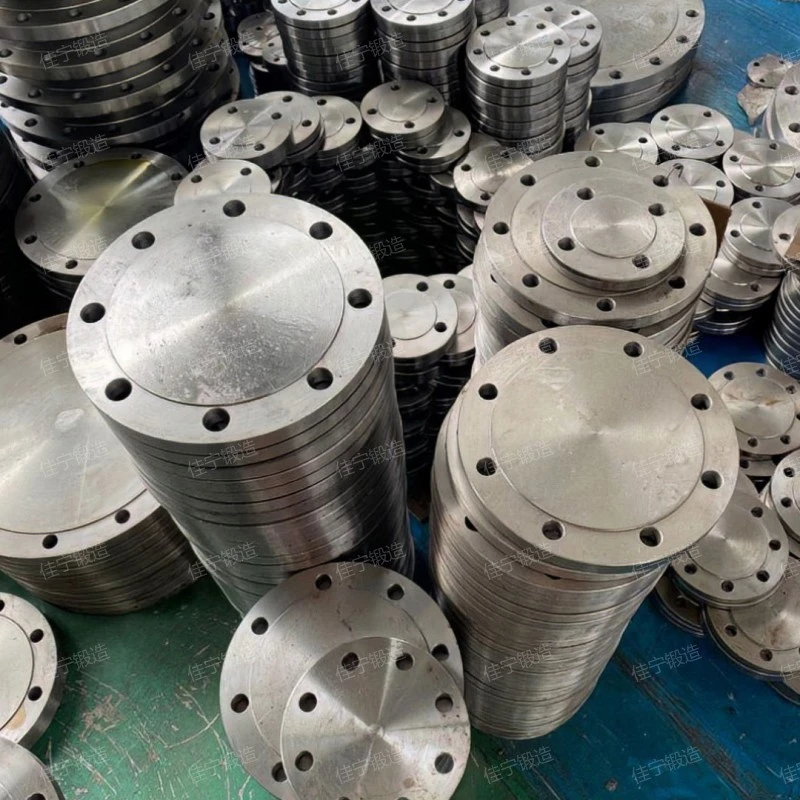

3、Low temperature steel cylinder forging parts field real shot

Jianing forging Low temperature steel cylinder forging partsthe product looks atmospheric., the picture is taken.。

Low temperature steel cylinder forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

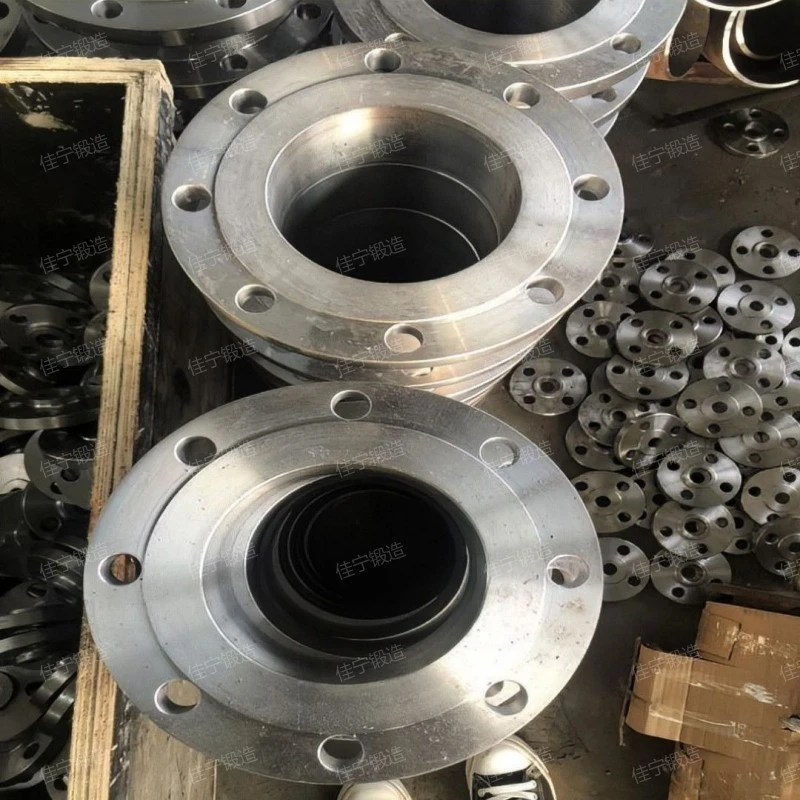

4、Low temperature steel cylinder forging parts HD picture real shot

Low temperature steel cylinder forging parts specifications and models are complete, and customers can choose at will. High-definition pictures are available for customers' reference. Customers are welcome to visit our factory.。

Low temperature steel cylinder forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Introduction of Low temperature steel cylinder forging parts characteristics

Low temperature steel cylinder forging partsit has the characteristics of Can bear large impact force or heavy load., Great forging flexibility, high-precision, high-intensity and Good anti-fatigue performance,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,the product looks beautiful.,is a Low temperature steel cylinder forging parts,reliable quality。

Low temperature steel cylinder forging parts

Low temperature steel cylinder forging partsit can be used in shipping, automobile, war industry, power, construction machinery and other industries,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Low temperature steel cylinder forging parts can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Low temperature steel cylinder forging parts.。

Related recommendation

-

What is a Forged steel free forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to Round steel free forging and forging advantages and features

2025-5-26 -

Introduction to Flat neck butt welded flange ring, flange specifications, model parameters

2025-5-26 -

What is a Rolling mill bearing forging parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

铝镁合金车轮锻件

2024-12-10 -

What is a Q255C carbon steel forgings? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a DN1100 flange ring? flange specifications, models, and parameters

2025-5-26 -

What is a 30 # forged steel component? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Convex flat welding plate flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Tenon groove flange and flange advantages and features

2025-5-26