What is a Alloy steel shaft forged parts? Introduction to the Working Principle of forging

Alloy steel shaft forged partsis a workpiece or blank obtained by forging and deforming a metal blank.,is a common Alloy steel shaft forged parts。The following is to introduce the Alloy steel shaft forged parts:

1、Brief introduction of Alloy steel shaft forged parts

Alloy steel shaft forged partsthe forging machine is used to exert pressure on the blank.,usually used in metallurgy, automobile, war industry, rail traffic, shipping and other fields,it has the characteristics of High production efficiency, Good mechanical properties, Good anti-fatigue performance, high-intensity and Good mechanical properties。

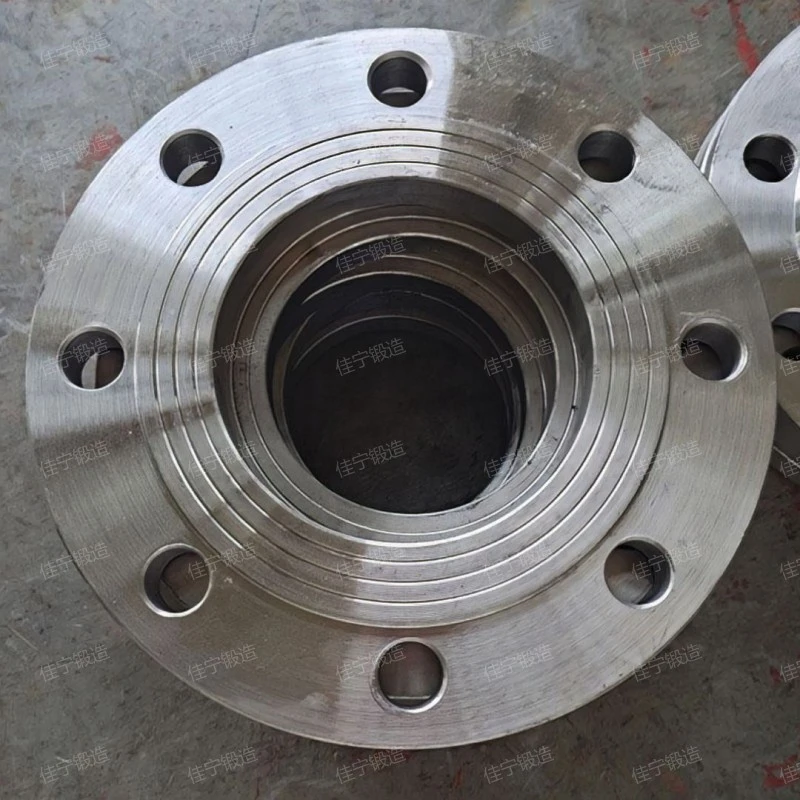

Alloy steel shaft forged parts

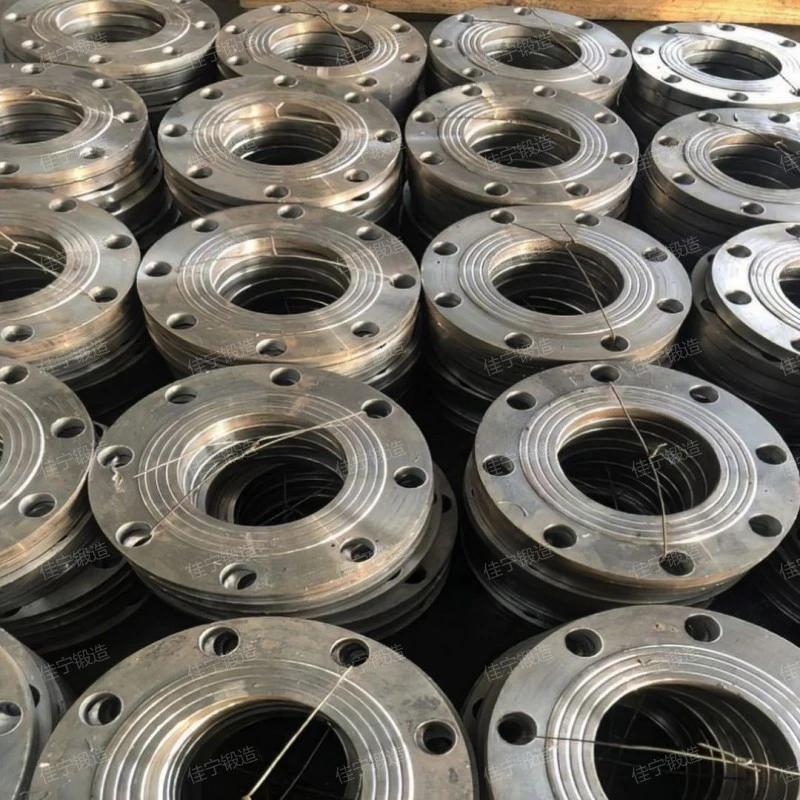

2、Alloy steel shaft forged parts working site

On-site aerial photography of Alloy steel shaft forged parts。

Alloy steel shaft forged parts

As you can see from the live video.,Jianing is a common Alloy steel shaft forged parts。

3、Alloy steel shaft forged parts advantage

The advantages of Alloy steel shaft forged parts are as follows:

- High degree of automation

- Replace other processing methods

- high-intensity

- Meet the requirements of complex working conditions

- Perfect quality assurance system

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In some cases, Alloy steel shaft forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The Alloy steel shaft forged parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the process of Alloy steel shaft forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Alloy steel shaft forged parts.

Alloy steel shaft forged parts

4、Alloy steel shaft forged parts characteristics

Alloy steel shaft forged partsfeatures include High productivity, High production efficiency, high tenacity, Light weight and Save raw materials,it is widely used in power, construction machinery, energy, manufacturing industry, metallurgy and other industries,the product looks beautiful.,forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,it has been widely used in energy, war industry, construction machinery, power, automobile and other industries。

Alloy steel shaft forged parts

5、How much is the Alloy steel shaft forged parts?

The Alloy steel shaft forged parts price is introduced as follows:

- After-sales service level

- Configuration difference

- Quality advantages and disadvantages

- raw material

- regional difference

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Alloy steel shaft forged parts price and service can meet the actual needs of customers.

Usually, the quotation of Alloy steel shaft forged parts changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

The price of Alloy steel shaft forged parts is affected by the quality of products. Only when the products are of good quality can we create greater profits for customers and recover the costs for customers as soon as possible. However, products with good quality have a lot of investment in technology, manpower and time, so their prices are higher than those of ordinary products. On the contrary, the products of general quality are equal in effort and gain, and the sales price is also low. But there are exceptions. Many manufacturers often adopt the mode of small profits but quick turnover. If customers can choose products with high cost performance, it is a good choice for long-term investment.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing forging address:Shanxi Xinzhou, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Alloy steel shaft forged parts

6、Jianing introduced

Jianing forging is a professional and large-scale Alloy steel shaft forged parts manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Alloy steel shaft forged parts manufacturer trusted by consumers at present.。

Jianing

Alloy steel shaft forged partsthe product looks beautiful.,is a Alloy steel shaft forged parts,Can bear large impact force or heavy load.,high-precision,Great forging flexibility,Light weight,Can bear large impact force or heavy load.。

Related recommendation

-

Introduction to Round socket forged parts and forging advantages and features

2025-5-26 -

What is a Marine Ring Free Forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Plate welded steel flange and flange working principle

2025-5-26 -

Introduction to Bearing steel forged parts and forging working principle

2025-5-26 -

Introduction to 35CrMo shaft forging, introduction to forging function advantages and characteristics

2025-5-26 -

What is a 30Cr forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Forged steel flat welding flange plate and flange structure principle

2025-5-26 -

What is a Big head shaft forging parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a 25 # steel free forging? Introduction to the Working Principle of forging

2025-5-26 -

What is a Ring neck welded flange cover? Introduction to the Working Principle of flange

2025-5-26