Introduction to Conical spindle free forging, advantages, characteristics and principles of forging

Conical spindle free forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。The following is to introduce the Conical spindle free forging:

1、Brief introduction of Conical spindle free forging

Conical spindle free forgingplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,The price is relatively low.。

Conical spindle free forging

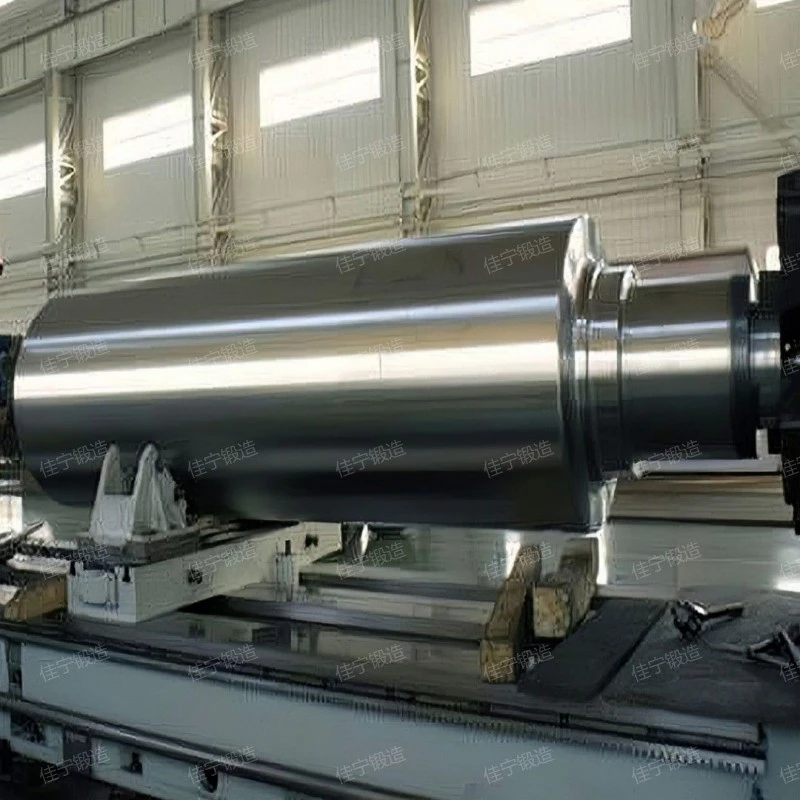

2、Conical spindle free forging field real shot

Speak directly with facts on the spot。

Conical spindle free forging

As you can see from the live video.,Jianing the advantage is After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Conical spindle free forging.、After forging, its structure and mechanical properties can be improved.。

3、Introduction of advantages of Conical spindle free forging

Conical spindle free forgings have the following advantages.

- high-intensity

- Good chemical uniformity

- Meet the requirements of complex working conditions

- Reduce the amount of subsequent processing

- Perfect quality assurance system

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging can disperse the segregation of alloy or nonmetal and make the Conical spindle free forging have excellent chemical uniformity.

The Conical spindle free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The forming precision of the Conical spindle free forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the process of Conical spindle free forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Conical spindle free forging.

Conical spindle free forging

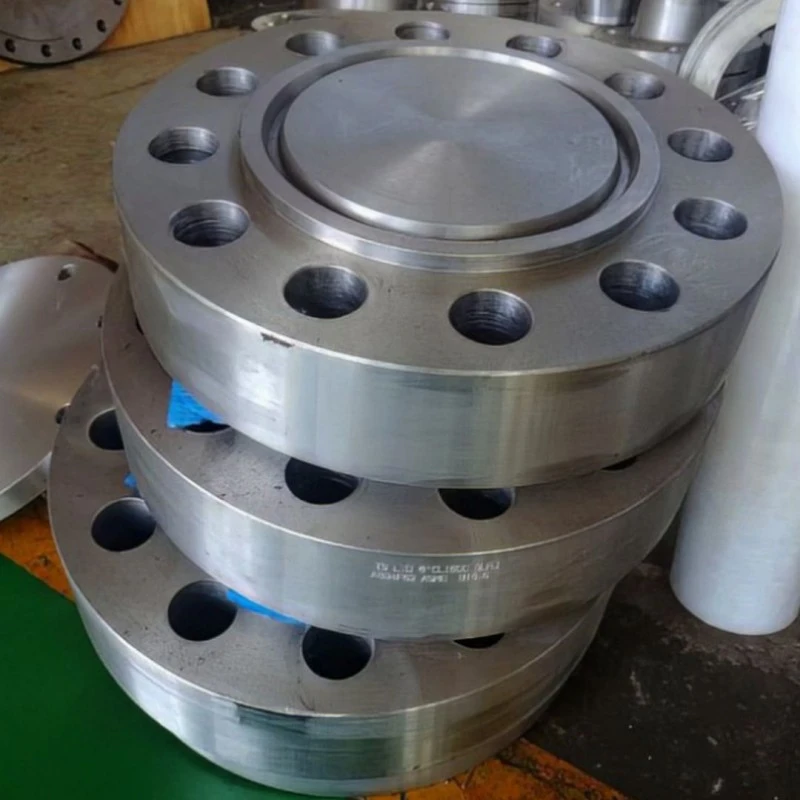

4、Conical spindle free forging display

The design of Jianing forging Conical spindle free forging is exquisite and elegant. Here are the high-definition pictures of Jianing's factory products for our customers' reference. We need to make an appointment to visit the factory in advance for physical inspection.。

Conical spindle free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Conical spindle free forging characteristics

Conical spindle free forginghigh-intensity,high tenacity,High productivity,high-precision,Light weight。

Conical spindle free forging

6、Brief introduction of Conical spindle free forging

Conical spindle free forgingis a workpiece or blank obtained by forging and deforming a metal blank.,widely used inrail traffic,war industry,metallurgy,power,energy and other industries。

Conical spindle free forging

Conical spindle free forgingis a Conical spindle free forging,the product looks beautiful.,the main features are Good mechanical properties, Good anti-fatigue performance, Can bear large impact force or heavy load., High production efficiency and Great forging flexibility。

Related recommendation

-

Introduction to Forged parts of pressure vessel end caps, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to High pressure cylinder free forging and forging working principle

2025-5-26 -

What is a Nickel alloy pressure vessel forging parts? Introduction to the principle of forging structure

2025-5-26 -

What is a 20MnMoNb Ring Forging Parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a 4130 alloy free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to 20Mn free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Transmission gear forgings and gear structure principle

2025-5-26 -

What is a Nut flat welding flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Plate stainless steel flat welding flange ring, how much is the price of the flange?

2025-5-26 -

Introduction to Welding protrusion flange, flange advantages, characteristics and principles

2025-5-26