Introduction to Forged parts of pressure vessel end caps, introduction to forging advantages and characteristics

Forged parts of pressure vessel end capsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a kind of high quality and low price Forged parts of pressure vessel end caps,widely used inmanufacturing industry,pressure vessel,energy,metallurgy,rail traffic and other industries。The following is to introduce the Forged parts of pressure vessel end caps:

1、Brief introduction of Forged parts of pressure vessel end caps

Forged parts of pressure vessel end capsthe forging machine is used to exert pressure on the blank.,it has the characteristics of Great forging flexibility, Good mechanical properties, Can bear large impact force or heavy load., Light weight and high-precision,super quality and competitive price。

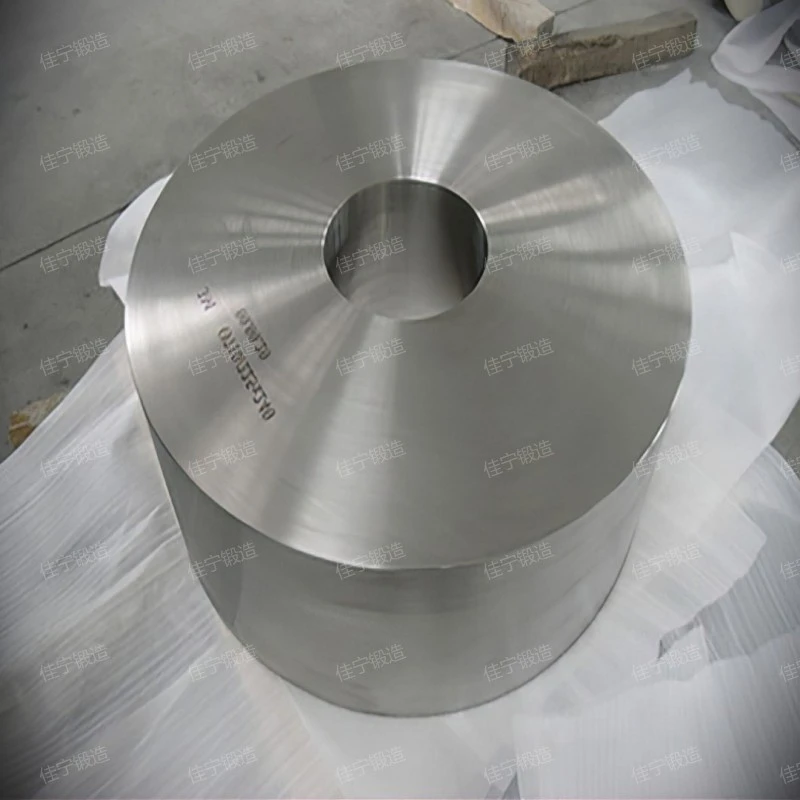

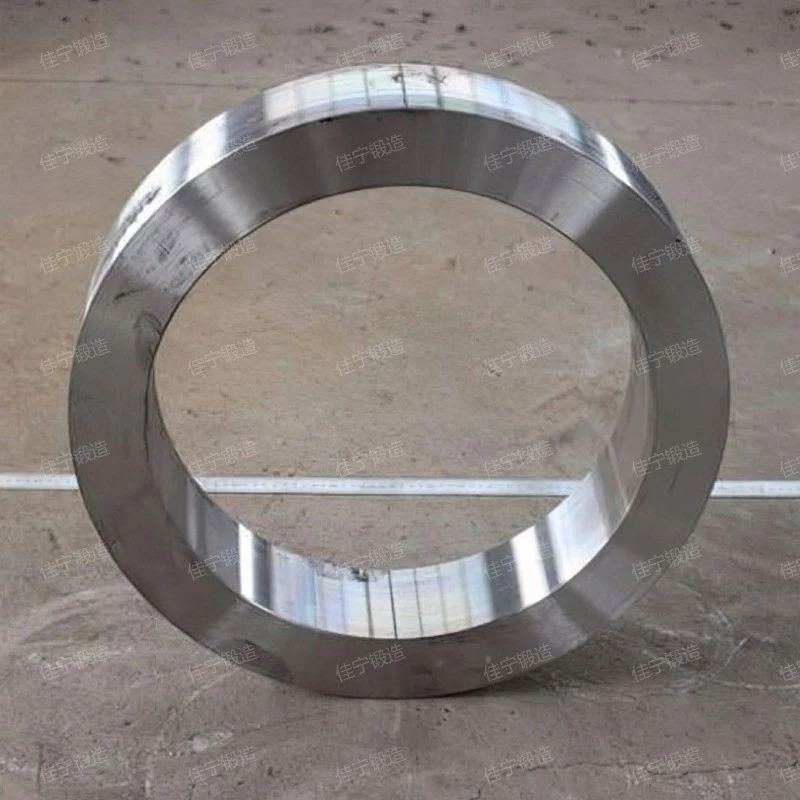

Forged parts of pressure vessel end caps

2、Forged parts of pressure vessel end caps field real shot

You can buy Forged parts of pressure vessel end caps according to your needs and show you Forged parts of pressure vessel end caps videos.。

Forged parts of pressure vessel end caps

As you can see from the live video.,Jianing forging the product looks atmospheric.。

3、Forged parts of pressure vessel end caps performance advantage

The advantages of Forged parts of pressure vessel end caps are as follows:

- Reduce the amount of subsequent processing

- Perfect quality assurance system

- Improve material utilization rate

- Reduce the amount of subsequent processing

- high-intensity

The forming precision of the Forged parts of pressure vessel end caps is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the process of Forged parts of pressure vessel end caps production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of pressure vessel end caps.

In the process of Forged parts of pressure vessel end caps production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The forming precision of the Forged parts of pressure vessel end caps is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forged parts of pressure vessel end caps

4、Introduction of Forged parts of pressure vessel end caps characteristics

Forged parts of pressure vessel end capsGood anti-fatigue performance,Good mechanical properties,high tenacity,Good anti-fatigue performance,High productivity,the product looks beautiful.,plastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

Forged parts of pressure vessel end caps

5、Forged parts of pressure vessel end caps price consultation

The Forged parts of pressure vessel end caps price is introduced as follows:

- product configuration

- market supply and demand

- raw material

- Brand strength

- regional difference

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. Jianing has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

Market supply and demand is the main objective factor to determine the price, and the imbalance between supply and demand affects the price change. Generally speaking, when the Forged parts of pressure vessel end caps market is in short supply, its price will increase relatively; On the contrary, when the supply exceeds the demand, it also indicates that the competition among manufacturers is fierce. In order to better improve the visibility of manufacturers and occupy a more favorable market position, manufacturers will generally lower their prices appropriately; Only when the market supply and demand reach a balanced state can its normal price be realized.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

At present, there are various brands of Forged parts of pressure vessel end caps in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Forged parts of pressure vessel end caps are different.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

Forged parts of pressure vessel end caps

6、Jianing forging company service

It takes a long time to buy the product back, and if the after-sales service is not guaranteed, it will also produce higher expenses. Therefore, when purchasing the Forged parts of pressure vessel end caps, we should pay special attention to the after-sales situation of the manufacturer. Jianing provides customers with perfect pre-sale, in-sale and after-sale services, completely dispelling customers' worries and enjoying Jianing forging's full-station service experience with peace of mind.。

Jianing

Forged parts of pressure vessel end capsit can be used in construction machinery, pressure vessel, energy, automobile, shipping and other industries,the main features are Light weight, Save raw materials, Can bear large impact force or heavy load., High production efficiency and high-precision,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

Related recommendation

-

What is a Q235 flat welding flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Wind power reverse balance flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Q255B carbon steel forgings and forging working principle

2025-5-26 -

What is a Grade III pressure vessel forgings? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Convex neck concave flange ring, flange advantages, characteristics and principles

2025-5-26 -

What is a Special steel free forging? Introduction to the principle of forging structure

2025-5-26 -

Introduction to Oil cylinder base forging, introduction to forging function advantages and characteristics

2025-5-26 -

What is a Pressure bearing blind flange? Introduction to the principle of blind plate structure

2025-5-26 -

What is a 25CrMo free forging? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Flat welded B-type flange ring, flange specifications, model parameters

2025-5-26