Introduction to Free forging of rolling mill roll shaft, forging advantages, characteristics and principles

Free forging of rolling mill roll shaftforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Free forging of rolling mill roll shaft can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Free forging of rolling mill roll shaft.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

1、Brief introduction of Free forging of rolling mill roll shaft

Free forging of rolling mill roll shaftis a workpiece or blank obtained by forging and deforming a metal blank.,the main features are high tenacity, Good anti-fatigue performance, Good mechanical properties, Light weight and Can bear large impact force or heavy load.,is a Free forging of rolling mill roll shaft,is developed and improved by Jianing。

Free forging of rolling mill roll shaft

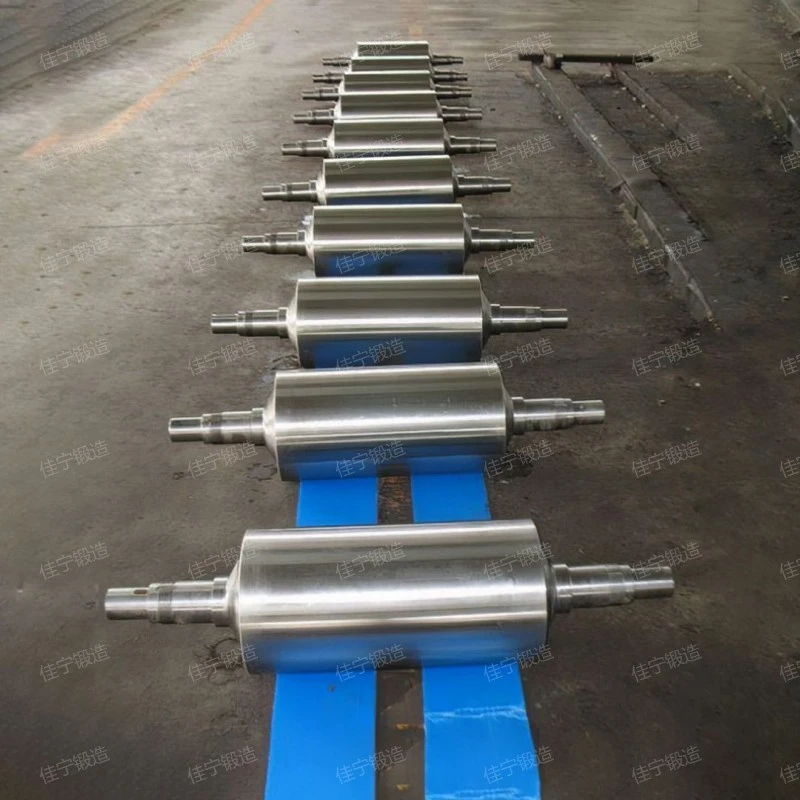

2、Free forging of rolling mill roll shaft display

The details of the Free forging of rolling mill roll shaft are displayed in many directions, and the Free forging of rolling mill roll shaft is beautiful and cost-effective.。

Free forging of rolling mill roll shaft

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Introduction of advantages of Free forging of rolling mill roll shaft

Free forging of rolling mill roll shafts have the following advantages.

- Improve material utilization rate

- high tenacity

- High degree of automation

- Perfect quality assurance system

- High dimensional accuracy

In the process of Free forging of rolling mill roll shaft production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The fiber structure of the Free forging of rolling mill roll shaft is reasonably distributed, which improves the toughness of the material and enables the Free forging of rolling mill roll shaft to bear greater impact force and alternating stress.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of Free forging of rolling mill roll shaft production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Free forging of rolling mill roll shaft.

In the forging process of Free forging of rolling mill roll shaft, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Free forging of rolling mill roll shaft

4、Free forging of rolling mill roll shaft characteristics

Free forging of rolling mill roll shaftit has the characteristics of high-intensity, Great forging flexibility, High production efficiency, high-precision and High productivity。

Free forging of rolling mill roll shaft

5、Free forging of rolling mill roll shaft field real shot

On-site aerial photography of Free forging of rolling mill roll shaft。

Free forging of rolling mill roll shaft

As you can see from the live video.,Jianing is a Free forging of rolling mill roll shaft。

6、Free forging of rolling mill roll shaft price consultation

The Free forging of rolling mill roll shaft price is introduced as follows:

- select a qualified person

- quality

- Reasonable cost

- marketing channel

- technology

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

The quality of products provided by different manufacturers is different, so their prices will be different. Generally, large manufacturers provide products with higher quality, and the cost of technology and materials is more, so the price is relatively high. However, such products have better use effect and can bring longer-term benefits to customers.

The production cost is mainly the purchase of raw materials. Jianing forging attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, Jianing strives to reduce the input cost of products, and customers are very satisfied with this.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Free forging of rolling mill roll shaft

Free forging of rolling mill roll shaftis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Free forging of rolling mill roll shaft.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Free forging of rolling mill roll shaft can be improved.。

Related recommendation

-

What is a Roller forged parts? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Flat welding flange cover with raised surface plate, introduction to flange advantages and characteristics

2025-5-26 -

What is a Free forging of shaft sleeve? Introduction to the principle of forging structure

2025-5-26 -

What is a 30CrNi3 forged parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a Outer ring free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Free forging disc? forging specifications, models, and parameters

2025-5-26 -

Introduction to Q345B blind plate, blind plate advantages, characteristics and principles

2025-5-26 -

钻杆轴锻件

2024-12-10 -

What is a Threaded round mouth flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

耐冲击工具钢锻件

2024-12-10