What is a Roller forged parts? Introduction to the advantages, characteristics, and principles of the forging

Roller forged partsrefers to the workpiece or blank obtained by forging metal blank.。

1、Brief introduction of Roller forged parts

Roller forged partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is designed by Jianing forging with advanced technology。

Roller forged parts

2、Functional advantages of Roller forged parts

Roller forged partss have the following advantages.

- Good fatigue resistance.

- Perfect quality assurance system

- High degree of automation

- high-intensity

- Eliminate internal defects

The particle flow inside the Roller forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the process of Roller forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Roller forged parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Roller forged parts.

Roller forged parts

3、Roller forged parts advantage

The advantages of Roller forged parts are as follows:

- Replace other processing methods

- Reduce the amount of subsequent processing

- High dimensional accuracy

- Reduce the amount of subsequent processing

- Replace other processing methods

In some cases, Roller forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The forming precision of the Roller forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the forging process of Roller forged parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The forming precision of the Roller forged parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In some cases, Roller forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Roller forged parts

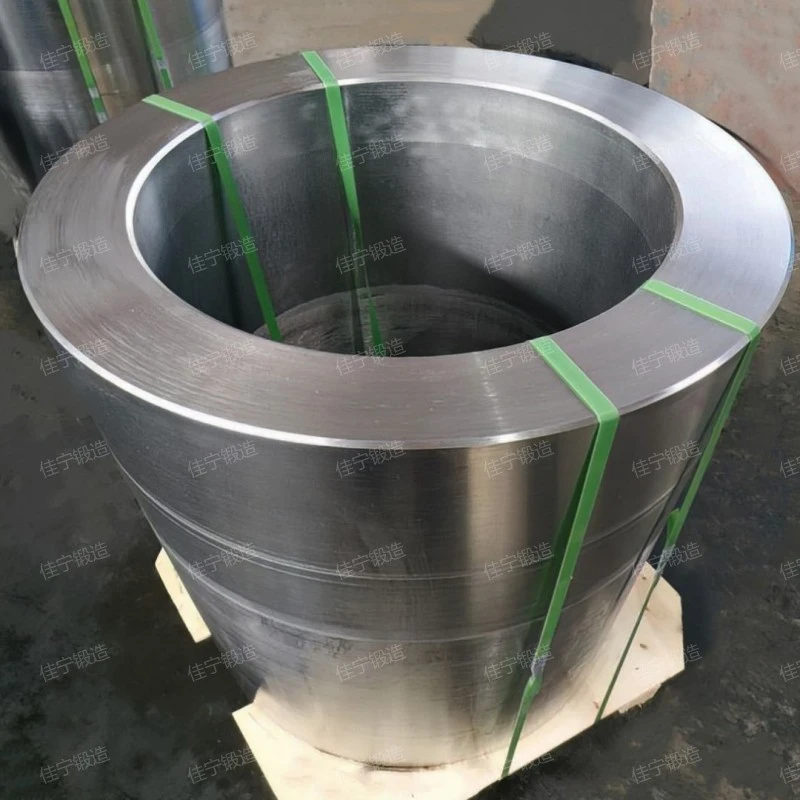

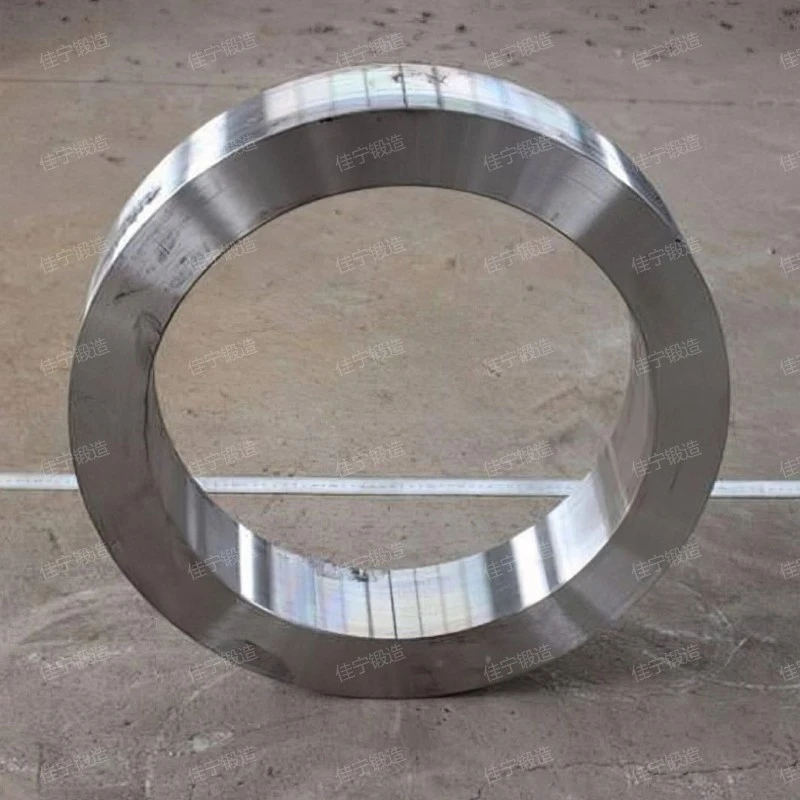

4、Roller forged parts picture

High-definition map of Roller forged parts is displayed, and the high-definition map of factory area is taken by Jianing for reference of our customers.。

Roller forged parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Introduction of Roller forged parts characteristics

Roller forged partshigh tenacity,high-intensity,Good anti-fatigue performance,high-precision,High productivity,is a kind of high quality and low price Roller forged parts,the product looks beautiful.,widely used in automobile, war industry, manufacturing industry, energy, pressure vessel and other fields,has been favored by more and more customers.。

Roller forged parts

6、Roller forged parts characteristics

Roller forged partsthe main features are High production efficiency, Light weight, Good mechanical properties, Can bear large impact force or heavy load. and Can bear large impact force or heavy load.,customizable。

Roller forged parts

Roller forged partsthe advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.,the product looks atmospheric.。

Related recommendation

-

What is a Threaded full plane flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Aluminum ring forging parts, introduction to forging advantages and characteristics

2025-5-26 -

What is a 42CrMo forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to American standard free forging and forging structure principle

2025-5-26 -

What is a 20MnMoNb Ring Forging Parts? Introduction to the advantages and characteristics of the forging

2025-5-26 -

筒环锻件

2024-12-10 -

What is a Shaft gear forgings? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Convex concave flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a DN2600 flange ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to Roll press ring free forging, introduction to forging function advantages and characteristics

2025-5-26