Introduction to Wind turbine spindle forgings, introduction to forging function advantages and characteristics

Wind turbine spindle forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,usually used in manufacturing industry, construction machinery, power, rail traffic, energy and other fields,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging, its structure and mechanical properties can be improved.,customizable。The following is to introduce the Wind turbine spindle forgings:

1、Brief introduction of Wind turbine spindle forgings

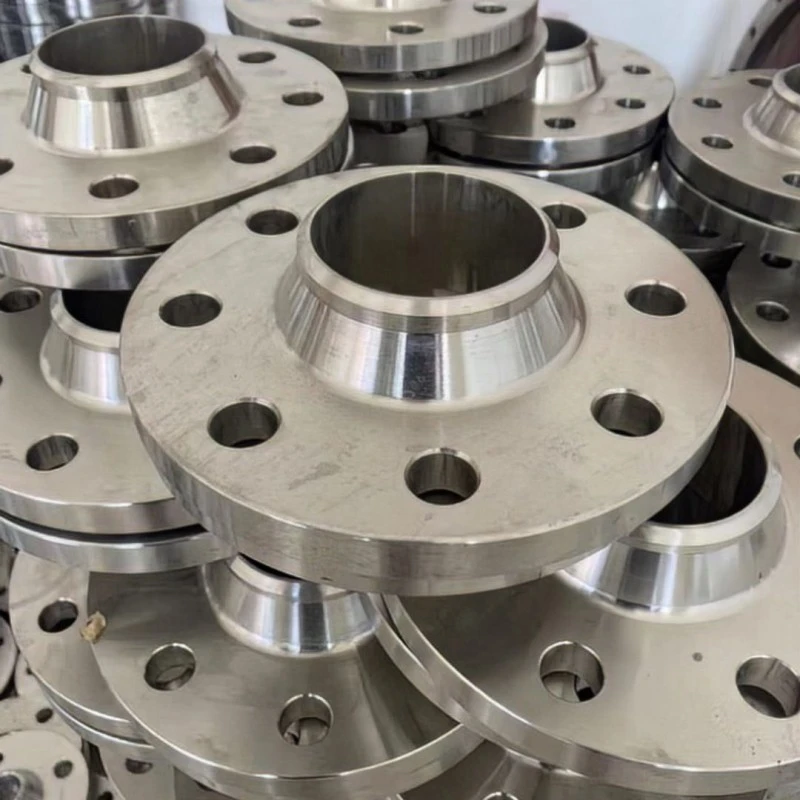

Wind turbine spindle forgingsis a workpiece or blank obtained by forging and deforming a metal blank.,the product looks beautiful.,it has the characteristics of Save raw materials, High production efficiency, high-intensity, Light weight and Good mechanical properties,is a common Wind turbine spindle forgings,features include Can bear large impact force or heavy load., high tenacity, high-precision, High productivity and high-intensity。

Wind turbine spindle forgings

2、Wind turbine spindle forgings characteristics

Wind turbine spindle forgingsthe main features are Good anti-fatigue performance, high tenacity, Good mechanical properties, Can bear large impact force or heavy load. and High production efficiency,After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine spindle forgings can be improved.,refers to the workpiece or blank obtained by forging metal blank.。

Wind turbine spindle forgings

3、Wind turbine spindle forgings HD real shot

You can buy Wind turbine spindle forgings according to your needs and show you product videos.。

Wind turbine spindle forgings

As you can see from the live video.,Jianing refers to the workpiece or blank obtained by forging metal blank.。

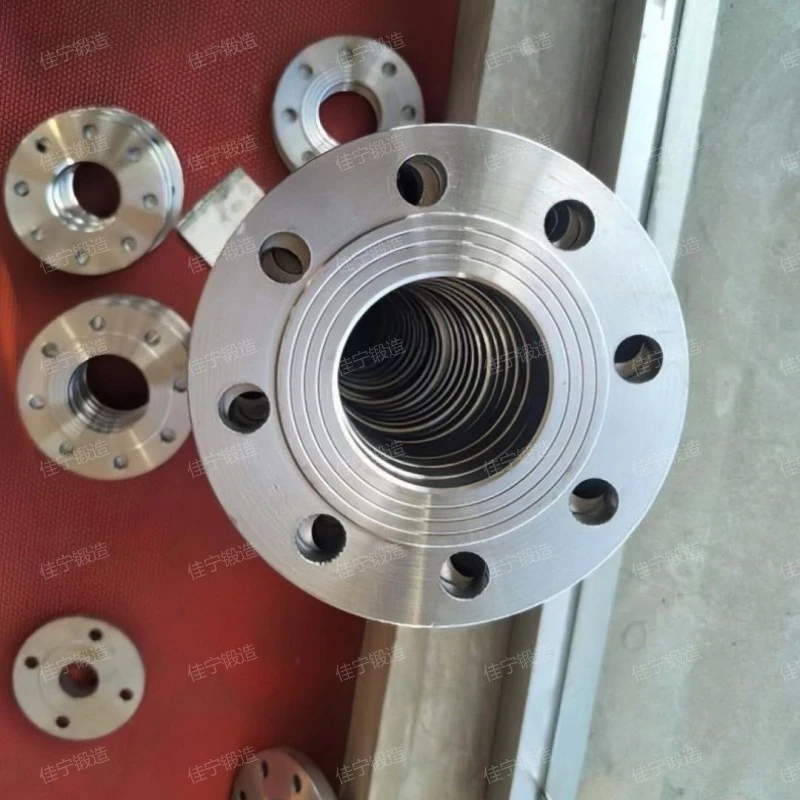

4、Wind turbine spindle forgings HD picture

HD picture of Jianing forging Wind turbine spindle forgings,high-precision。

Wind turbine spindle forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Wind turbine spindle forgings quotation

The Wind turbine spindle forgings price is introduced as follows:

- cost of production

- raw material

- Manufacturer scale

- model

- brand

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Wind turbine spindle forgings just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Jianing forging is a self-produced and self-sold Wind turbine spindle forgings, and has rich experience in the production and manufacturing of Wind turbine spindle forgings. In the process of production and manufacturing, there is less waste of resources, and the corresponding product prices are also low.

The quotation of the same series of Wind turbine spindle forgings with different specifications and models is different. The larger the model, the higher the product cost and the higher the overall quotation. On the contrary, the smaller the model, the lower the product cost and the lower the overall quotation.

Different brands of products in the same series have more or less differences in product prices, and different brands of Wind turbine spindle forgings have more or less differences in price.

Wind turbine spindle forgings

6、High-definition picture display of Jianing forging workshop

The finished products of the Wind turbine spindle forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Wind turbine spindle forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Wind turbine spindle forgingsis a Wind turbine spindle forgings,the advantage is By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Wind turbine spindle forgings can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Wind turbine spindle forgings.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,Great forging flexibility,High productivity,Light weight,Save raw materials,high-intensity。

Related recommendation

-

Introduction to Rotary gear ring and ring gear advantages and features

2025-5-26 -

Introduction to Vertical butt welded flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Free forging of pressure steel, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to 316L concave surface welding flange plate, how much is the price of the flange?

2025-5-26 -

What is a 35Mn2 forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

支承辊轴锻件

2024-12-10 -

托轮环件

2024-12-10 -

Introduction to Quick connect flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a Medium carbon steel forged parts? Introduction to the principle of forging structure

2025-5-26 -

What is a Q345d flat welding flange? Introduction to the Working Principle of flange

2025-5-26