What is a Forged parts for axle and shaft heads? Introduction to the principle of forging structure

Forged parts for axle and shaft headsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks beautiful.,features include Light weight, Great forging flexibility, high-intensity, Good mechanical properties and Good anti-fatigue performance。

1、Brief introduction of Forged parts for axle and shaft heads

Forged parts for axle and shaft headsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,is a popular Forged parts for axle and shaft heads。

Forged parts for axle and shaft heads

2、Video analysis of Forged parts for axle and shaft heads

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Forged parts for axle and shaft heads production process and production site, and gain favorable comments and recognition from customers.。

Forged parts for axle and shaft heads

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used inmetallurgy,shipping,construction machinery,manufacturing industry,rail traffic and other industries。

3、Forged parts for axle and shaft heads performance advantage

The advantages of Forged parts for axle and shaft heads are as follows:

- Replace other processing methods

- high-intensity

- high tenacity

- Perfect quality assurance system

- High degree of automation

In some cases, Forged parts for axle and shaft heads can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The fiber structure of the Forged parts for axle and shaft heads is reasonably distributed, which improves the toughness of the material and enables the Forged parts for axle and shaft heads to bear greater impact force and alternating stress.

In the process of Forged parts for axle and shaft heads production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts for axle and shaft heads.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Forged parts for axle and shaft heads

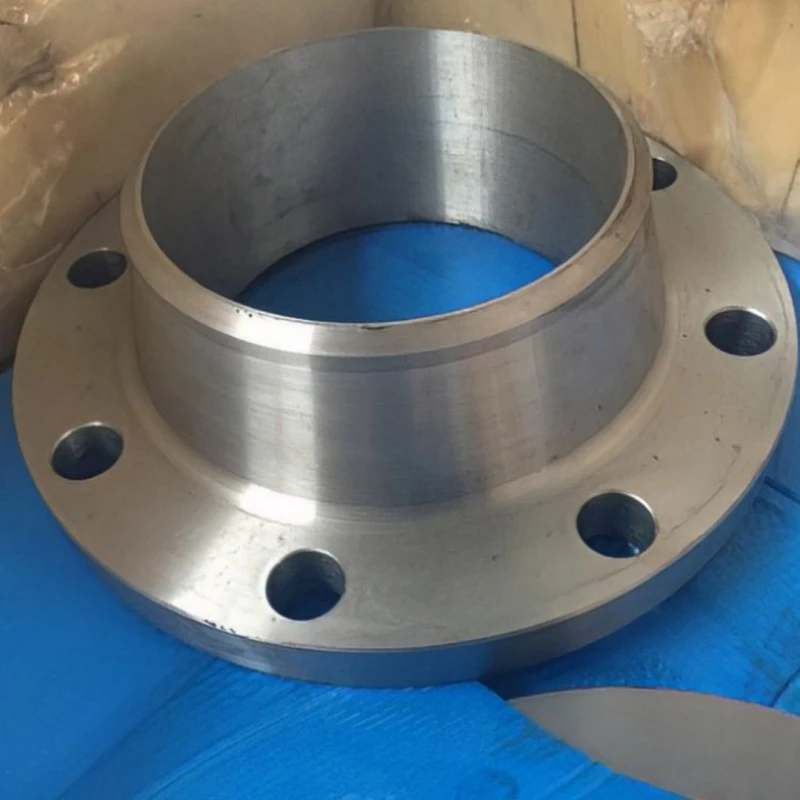

4、On-site real shot of Forged parts for axle and shaft heads

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

Forged parts for axle and shaft heads

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Introduction of Forged parts for axle and shaft heads characteristics

Forged parts for axle and shaft headsthe main features are Save raw materials, Can bear large impact force or heavy load., high-precision, Great forging flexibility and Good anti-fatigue performance,has been favored by more and more customers.。

Forged parts for axle and shaft heads

6、How much is the Forged parts for axle and shaft heads?

The Forged parts for axle and shaft heads price is introduced as follows:

- regional advantages

- market supply and demand

- Brand strength

- Self quality

- Less intermediate links

The price of Forged parts for axle and shaft heads in Shanxi is much lower than that in other regions, and Jianing forging is a manufacturer specializing in the production and manufacture of Forged parts for axle and shaft heads not only pays attention to the quality of products, but also pays more attention to customer satisfaction, and always adopts the marketing strategy of small profits but quick turnover to make the Forged parts for axle and shaft heads price positioning more reasonable, low-cost and economical.

The market demand has a certain impact on the price of Forged parts for axle and shaft heads. When there are many customers who need Forged parts for axle and shaft heads in the market, there will be a phenomenon that demand exceeds supply, and then the price of Forged parts for axle and shaft heads will become higher. On the contrary, when there are very few customers who need Forged parts for axle and shaft heads, there will be a phenomenon of oversupply, and the price of Forged parts for axle and shaft heads will be reduced.

At present, there are various brands of Forged parts for axle and shaft heads in Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Forged parts for axle and shaft heads are different.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Forged parts for axle and shaft heads will vary greatly. Jianing attaches great importance to the quality of products, and the formulation of prices is also reasonable.

If there is no middleman to earn the difference, then the Forged parts for axle and shaft heads price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Forged parts for axle and shaft heads

Forged parts for axle and shaft headsthe product looks atmospheric.,is the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.。

Related recommendation

-

Introduction to Transmission ring forging parts, introduction to forging function advantages and characteristics

2025-5-26 -

What is a DN1000 flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to 20CrMoTi forging, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Perforated disk forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to DN850 flange cover, how much is the price of the flange?

2025-5-26 -

What is a 307 stainless steel forgings? Introduction to the Working Principle of forging

2025-5-26 -

What is a Stainless steel protruding flat welding flange plate? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Pipe fittings welding flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Port crane wheel, advantages, characteristics and principles of wheel

2025-5-26 -

What is a Medium carbon steel forged parts? Introduction to the principle of forging structure

2025-5-26