Introduction to Forging parts for Class II pressure vessels, forging specifications, model parameters

Forging parts for Class II pressure vesselsthe forging machine is used to exert pressure on the blank.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forging parts for Class II pressure vessels can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it has the characteristics of Can bear large impact force or heavy load., high-intensity, Light weight, Save raw materials and Good anti-fatigue performance,has been favored by more and more customers.。

1、Brief introduction of Forging parts for Class II pressure vessels

Forging parts for Class II pressure vesselsrefers to the workpiece or blank obtained by forging metal blank.,it is widely used inconstruction machinery,construction machinery,war industry,power,metallurgy and other industries,is based on Jianing forging is a Forging parts for Class II pressure vessels newly developed by Jianing。

Forging parts for Class II pressure vessels

2、Forging parts for Class II pressure vessels introduction video

On-site aerial photography of Forging parts for Class II pressure vessels。

Forging parts for Class II pressure vessels

As you can see from the live video.,Jianing the product looks atmospheric.。

3、Introduction of Forging parts for Class II pressure vessels characteristics

Forging parts for Class II pressure vesselsit has the characteristics of Good mechanical properties, High productivity, High production efficiency, Can bear large impact force or heavy load. and Great forging flexibility,it can be used in manufacturing industry, rail traffic, automobile, manufacturing industry, pressure vessel and other industries,can be customized according to user's needs.。

Forging parts for Class II pressure vessels

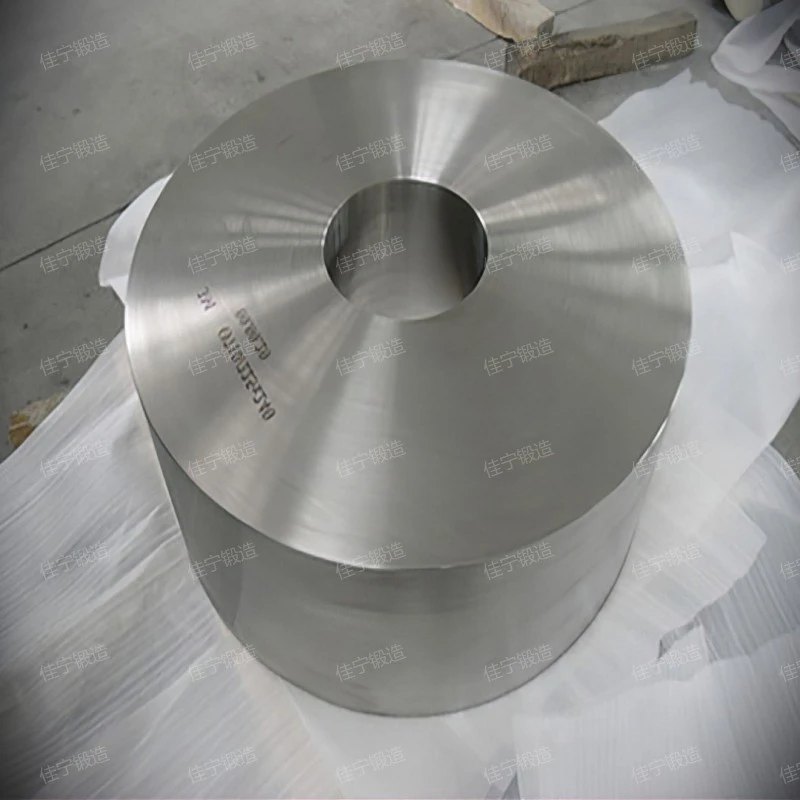

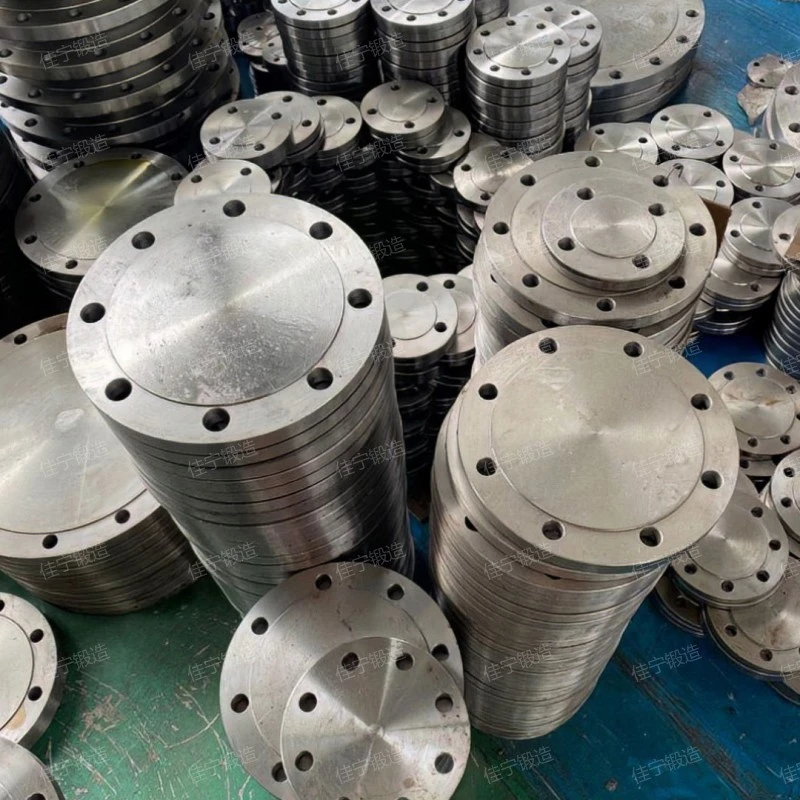

4、Forging parts for Class II pressure vessels field real shot

High-definition pictures of Forging parts for Class II pressure vessels of different specifications and models,the product looks atmospheric., reliable in quality and trustworthy.。

Forging parts for Class II pressure vessels

Note: All the pictures in this article were taken by Jianing manufacturer.。

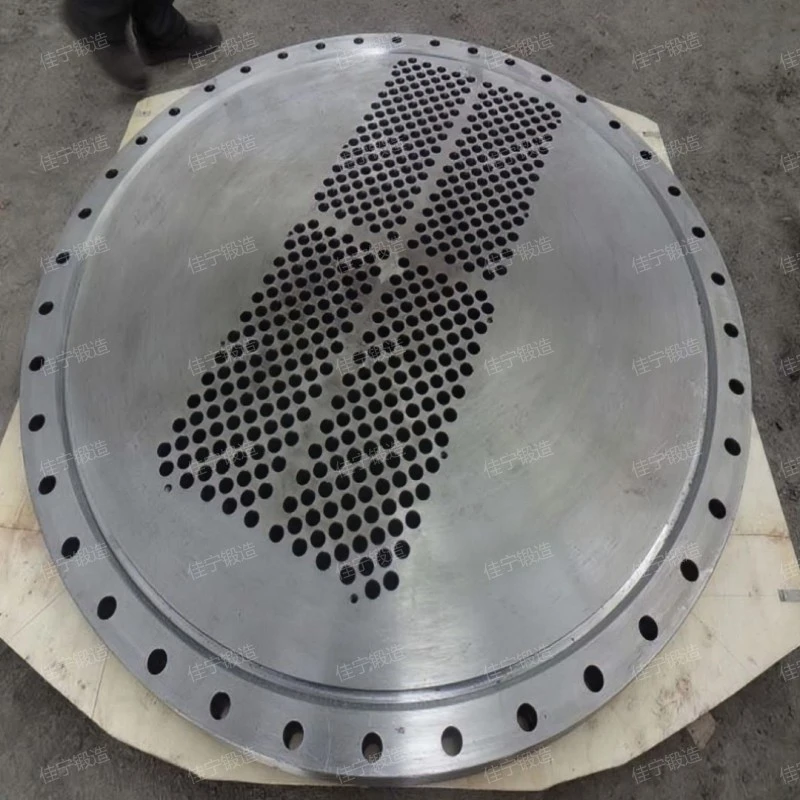

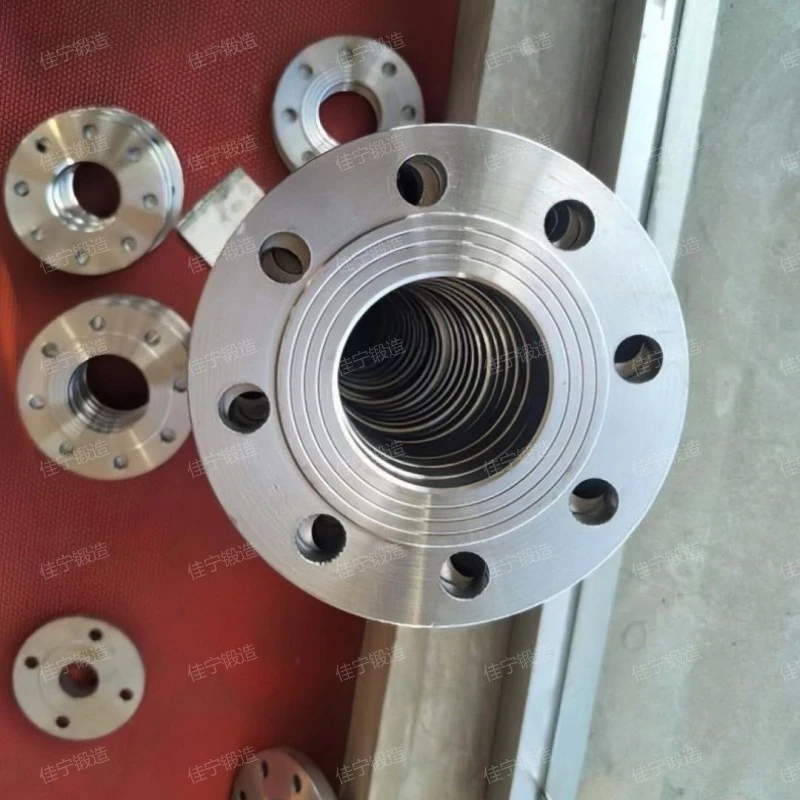

5、Physical picture of Forging parts for Class II pressure vessels

Overview of high-definition pictures,the product looks beautiful.。

Forging parts for Class II pressure vessels

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Jianing's strength

The company has many years of Forging parts for Class II pressure vessels manufacturing experience, large scale and strong strength.。

Jianing forging

Forging parts for Class II pressure vesselsForging can eliminate metal porosity and holes, and improve the mechanical properties of Forging parts for Class II pressure vessels.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forging parts for Class II pressure vessels.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,widely used inrail traffic,energy,pressure vessel,automobile,shipping and other industries。

Related recommendation

-

Introduction to Piston cylinder forging parts, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to Pressure vessel welding flange ring, flange specifications, model parameters

2025-5-26 -

What is a Carbon steel disc forgings? forging specifications, models, and parameters

2025-5-26 -

Introduction to Conical thread flange cover, flange advantages, characteristics and principles

2025-5-26 -

What is a Fan shaft free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Carbon steel flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Ring groove flange and flange working principle

2025-5-26 -

电力用法兰

2024-12-10 -

Introduction to Rolling mill roll shaft forgings and forging working principle

2025-5-26 -

Introduction to Square gear ring, how much is the price of the ring gear?

2025-5-26