Introduction to Half shaft forging, forging specifications, model parameters

Half shaft forgingis a workpiece or blank obtained by forging and deforming a metal blank.,is a Half shaft forging,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Half shaft forging.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Half shaft forging.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,it is widely used in metallurgy, energy, pressure vessel, manufacturing industry and war industry,is carefully developed by Jianing forging combined with advanced technology。The following is to introduce the Half shaft forging:

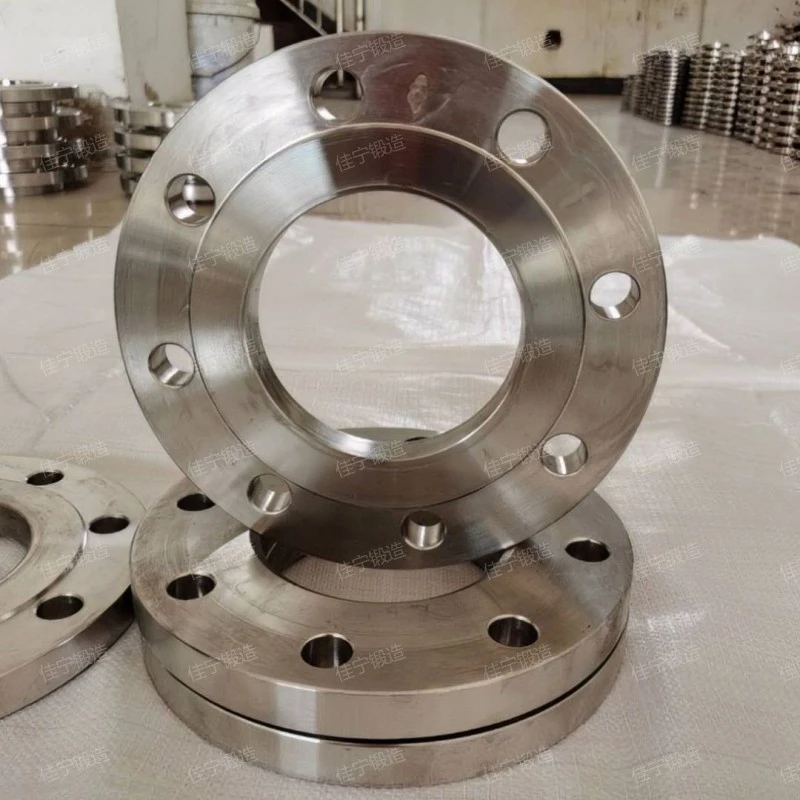

1、Brief introduction of Half shaft forging

Half shaft forgingrefers to the workpiece or blank obtained by forging metal blank.,Cheap and high quality。

Half shaft forging

2、Half shaft forging characteristics

Half shaft forgingfeatures include Good mechanical properties, High productivity, high-precision, Can bear large impact force or heavy load. and high tenacity。

Half shaft forging

3、Introduction of Half shaft forging characteristics

Half shaft forgingSave raw materials,high-precision,high-intensity,Great forging flexibility,Good mechanical properties,usually used in rail traffic, automobile, shipping, power, construction machinery and other fields,the product looks beautiful.,is a popular Half shaft forging,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Half shaft forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

Half shaft forging

4、Half shaft forging video

The following is the live video of Half shaft forging designed and produced by Jianing for users, from which we can see the the advantage is By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Half shaft forging can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved. of Jianing forgingHalf shaft forging.。

Half shaft forging

As you can see from the live video.,Jianing the product looks atmospheric.。

5、How much is the Half shaft forging?

The Half shaft forging price is introduced as follows:

- geographical position

- brand

- select a qualified person

- product function

- manufacturing cost

If the location of the manufacturer is superior, its transportation will be more convenient. Jianing forging detailed address:Cuijiazhuang Industrial Park in Dingxiang, Xinzhou City, Shanxi Province has convenient transportation, which provides a good convenience for the transportation of Half shaft forging.

Different brands of products in the same series have more or less differences in product prices, and different brands of Half shaft forging have more or less differences in price.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

Half shaft forging

6、Jianing forging's strength

The company has many years of Half shaft forging manufacturing experience, large scale and strong strength.。

Jianing

Half shaft forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Half shaft forging.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Half shaft forging can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

Related recommendation

-

Introduction to 35 # forged steel component, introduction to forging advantages and characteristics

2025-5-26 -

U71Mn车轮锻件

2024-12-10 -

Introduction to Valve box free forging and forging advantages and features

2025-5-26 -

Introduction to Low alloy steel forged parts and forging working principle

2025-5-26 -

立柱锻件

2024-12-10 -

Introduction to Orifice ring gear, ring gear specifications, model parameters

2025-5-26 -

What is a Q235B flat welded flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to DN250 flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Threaded full plane flange plate, how much is the price of the flange?

2025-5-26 -

Introduction to Gear ring, how much is the price of the gear?

2025-5-26