Introduction to Valve box free forging and forging advantages and features

Valve box free forgingrefers to the workpiece or blank obtained by forging metal blank.。The following is to introduce the Valve box free forging:

1、Brief introduction of Valve box free forging

Valve box free forgingthe forging machine is used to exert pressure on the blank.,is a popular Valve box free forging,is a Valve box free forging newly developed by Jianing。

Valve box free forging

2、Introduction of Valve box free forging characteristics

Valve box free forgingit has the characteristics of Can bear large impact force or heavy load., High productivity, High production efficiency, high-precision and Light weight,it is widely used in metallurgy, manufacturing industry, pressure vessel, shipping, energy and other industries,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve box free forging can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve box free forging.、After forging, its structure and mechanical properties can be improved.,is a kind of high quality and low price Valve box free forging,plastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

Valve box free forging

3、Valve box free forging advantage

The advantages of Valve box free forging are as follows:

- Reduce the amount of subsequent processing

- Eliminate internal defects

- Replace other processing methods

- Optimizing structural design

- Perfect quality assurance system

The forming precision of the Valve box free forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Valve box free forging.

In some cases, Valve box free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Valve box free forging can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Valve box free forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Valve box free forging.

Valve box free forging

4、Valve box free forging HD real shot

You can buy Valve box free forging according to your needs and show you Valve box free forging videos.。

Valve box free forging

As you can see from the live video.,Shanxi jianing forging co., ltd features include High production efficiency, high-intensity, high tenacity, Can bear large impact force or heavy load. and Good mechanical properties。

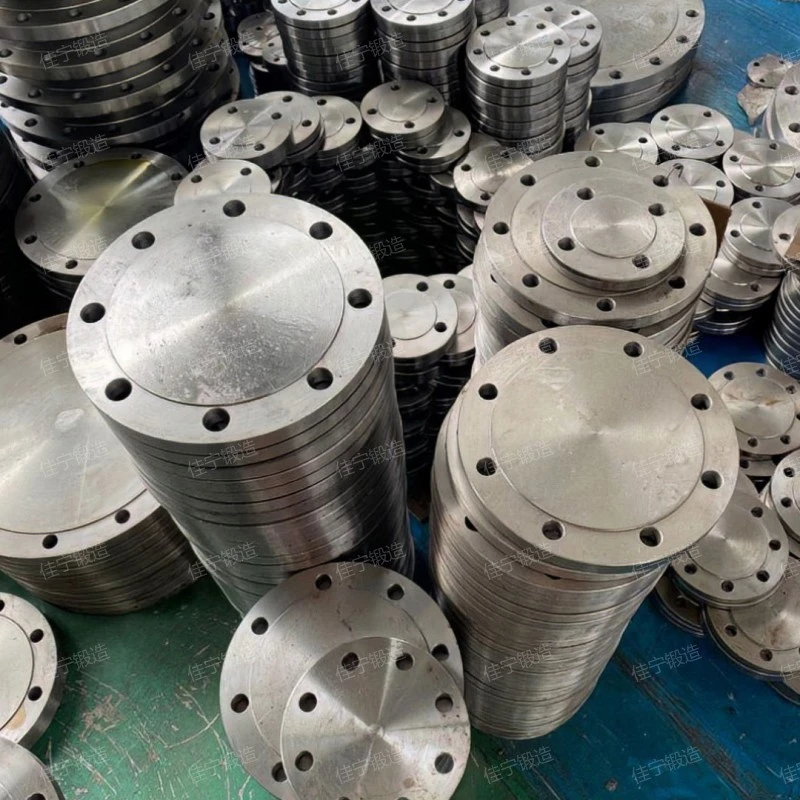

5、Valve box free forging HD real picture

Provide high-definition Valve box free forging real shot, a variety of specifications and models for customers to visit.。

Valve box free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

6、Valve box free forging quotation

The Valve box free forging price is introduced as follows:

- Product technology

- After-sales service level

- regional difference

- raw material

- Brand strength

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Valve box free forging price and service can meet the actual needs of customers.

Jianing forging detailed address:Cuijiazhuang Industrial Park in Dingxiang, Xinzhou City, Shanxi Province, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

The quality of material selection is one of the main factors that directly affect the Valve box free forging. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

At present, there are various brands of Valve box free forging in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Valve box free forging are different.

Valve box free forging

Valve box free forgingis a Valve box free forging,the product looks beautiful.,it can be used in pressure vessel, energy, rail traffic, shipping, power and other industries。

Related recommendation

-

Introduction to Docking flat welding flange cover and flange advantages and features

2025-5-26 -

What is a DN150 flange ring? flange specifications, models, and parameters

2025-5-26 -

火车轮辋锻件

2024-12-10 -

What is a Wind power gear? Introduction to the advantages, characteristics, and principles of the gear

2025-5-26 -

Introduction to DN50 flange and flange structure principle

2025-5-26 -

What is a 316L threaded flange ring? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Q345R gear, how much is the price of the gear?

2025-5-26 -

What is a Ring groove sealing face welding flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a RJ ring connection flange cover? Introduction to the Working Principle of flange

2025-5-26 -

What is a Forged parts of valve box? How much is the price of the forging?

2025-5-26