Introduction to Special equipment pressure vessel forging parts, introduction to forging function advantages and characteristics

Special equipment pressure vessel forging partsthe forging machine is used to exert pressure on the blank.。

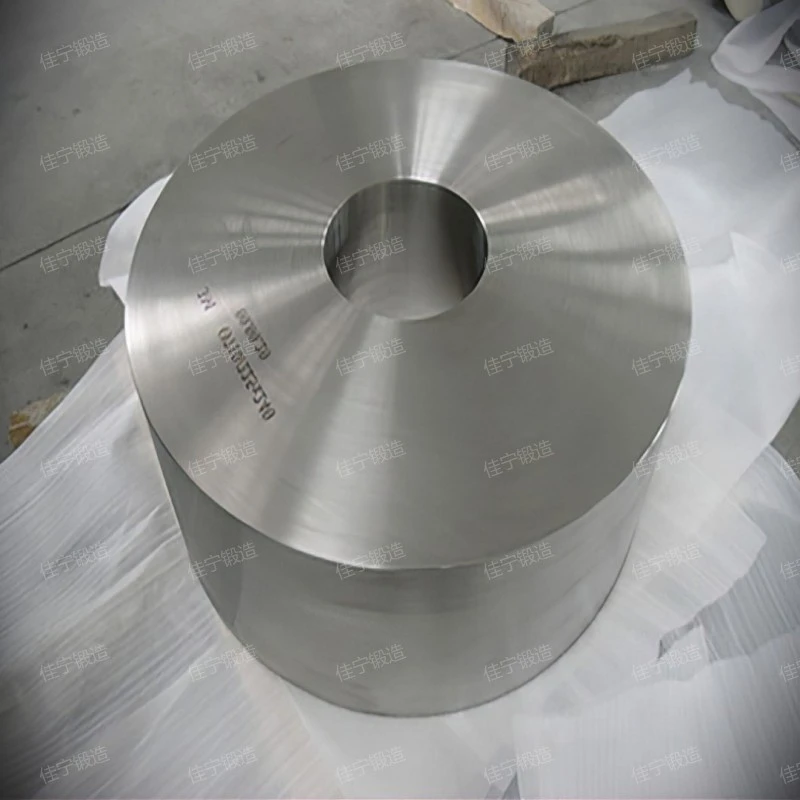

1、Brief introduction of Special equipment pressure vessel forging parts

Special equipment pressure vessel forging partsrefers to the workpiece or blank obtained by forging metal blank.,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,is carefully developed by Jianing combined with advanced technology。

Special equipment pressure vessel forging parts

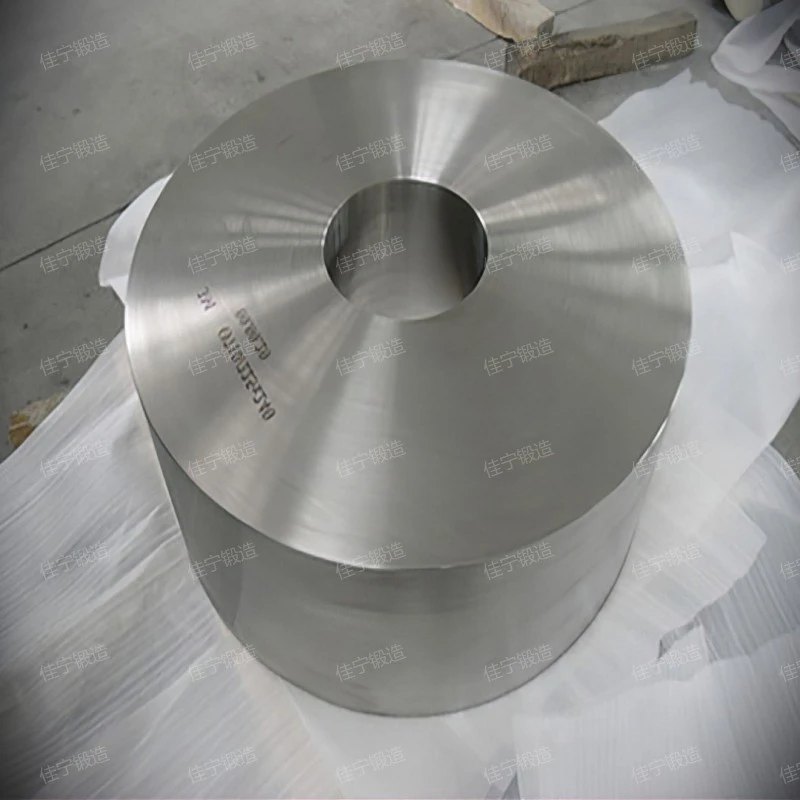

2、Special equipment pressure vessel forging parts performance advantage

Special equipment pressure vessel forging partss have the following advantages.

- Improve material utilization rate

- high tenacity

- High dimensional accuracy

- high-intensity

- Good fatigue resistance.

In the process of Special equipment pressure vessel forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The fiber structure of the Special equipment pressure vessel forging parts is reasonably distributed, which improves the toughness of the material and enables the Special equipment pressure vessel forging parts to bear greater impact force and alternating stress.

In the forging process of Special equipment pressure vessel forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The particle flow inside the Special equipment pressure vessel forging parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

Special equipment pressure vessel forging parts

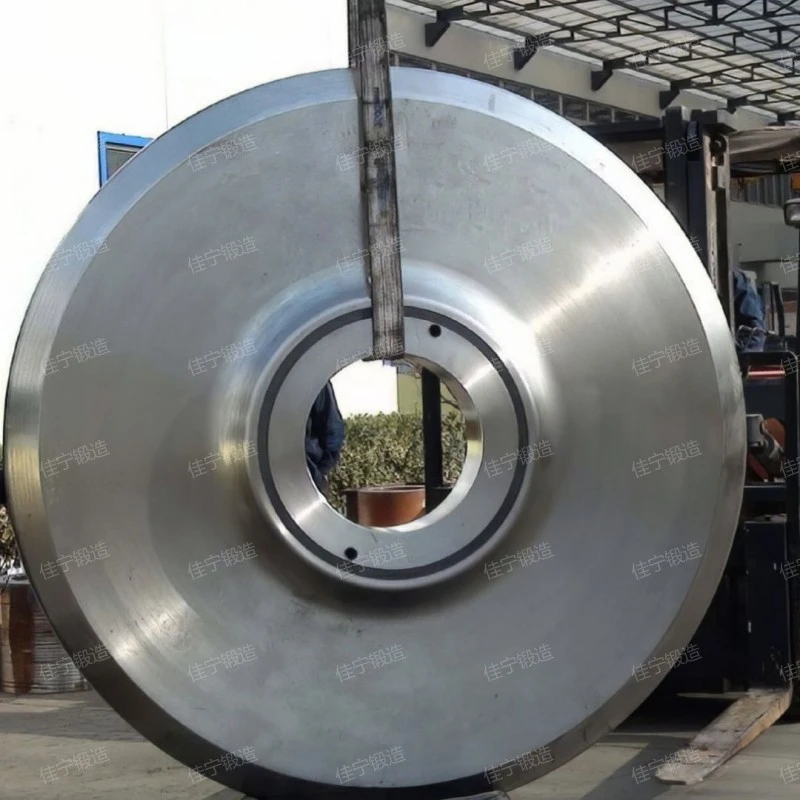

3、Special equipment pressure vessel forging parts introduction video

On-site aerial photography of Special equipment pressure vessel forging parts。

Special equipment pressure vessel forging parts

As you can see from the live video.,Jianing forging is a kind of high quality and low price Special equipment pressure vessel forging parts。

4、Introduction of advantages of Special equipment pressure vessel forging parts

The advantages of Special equipment pressure vessel forging parts are as follows:

- Eliminate internal defects

- Meet the requirements of complex working conditions

- Meet the requirements of complex working conditions

- Replace other processing methods

- Optimizing structural design

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Special equipment pressure vessel forging parts.

The Special equipment pressure vessel forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The Special equipment pressure vessel forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In some cases, Special equipment pressure vessel forging parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

On the premise of ensuring the design strength, through reasonable structural design, the Special equipment pressure vessel forging parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

Special equipment pressure vessel forging parts

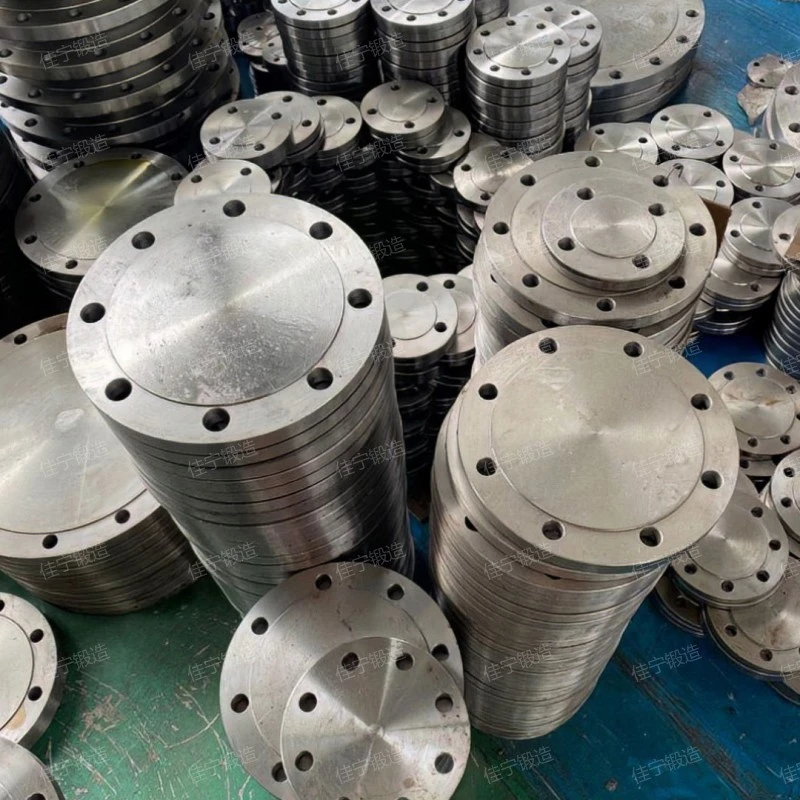

5、Introduction of Special equipment pressure vessel forging parts characteristics

Special equipment pressure vessel forging partsit has the characteristics of Great forging flexibility, Light weight, Save raw materials, high-intensity and Good mechanical properties,the product looks beautiful.,it has been widely used in rail traffic, power, shipping, rail traffic, pressure vessel and other industries,Cheap and high quality。

Special equipment pressure vessel forging parts

6、How much is the Special equipment pressure vessel forging parts?

The Special equipment pressure vessel forging parts price is introduced as follows:

- market factors

- product function

- product configuration

- Product technology

- Company size

When there are many customers who need this product in the market, and the supply quantity of the manufacturer is limited, there is not so much inventory at all. At this time, the demand will be in short supply, and the price of the Special equipment pressure vessel forging parts will be very high.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Products of the same style, different configurations, the product price is definitely different, therefore, the Special equipment pressure vessel forging parts price is affected by the configuration, and the price varies.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

Special equipment pressure vessel forging parts

Special equipment pressure vessel forging partsis a popular Special equipment pressure vessel forging parts,the product looks atmospheric.。

Related recommendation

-

Introduction to Q345c alloy forgings and forging structure principle

2025-5-26 -

Introduction to Threaded irregular flange and flange working principle

2025-5-26 -

What is a Manhole cover gear ring forgings? Introduction to the principle of ring gear structure

2025-5-26 -

Introduction to Half shaft sleeve forging parts and forging working principle

2025-5-26 -

Introduction to Aluminum ring forged parts and forging advantages and features

2025-5-26 -

Introduction to End cover flange cover and flange advantages and features

2025-5-26 -

Introduction to DN1200 flange ring and flange advantages and features

2025-5-26 -

Introduction to 20CrNiMo forged parts and forging structure principle

2025-5-26 -

Introduction to Oil cylinder tail forging, forging specifications, model parameters

2025-5-26 -

耐冲击工具钢锻件

2024-12-10