Introduction to Aluminum ring forged parts and forging advantages and features

Aluminum ring forged partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Aluminum ring forged parts can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,it is an ideal choice for customers to buy Aluminum ring forged parts。The following is to introduce the Aluminum ring forged parts:

1、Brief introduction of Aluminum ring forged parts

Aluminum ring forged partsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the main features are High production efficiency, high-precision, Save raw materials, Light weight and high-intensity,the product looks beautiful.,is a kind of high quality and low price Aluminum ring forged parts,the main features are Good anti-fatigue performance, High productivity, Great forging flexibility, Can bear large impact force or heavy load. and Good mechanical properties。

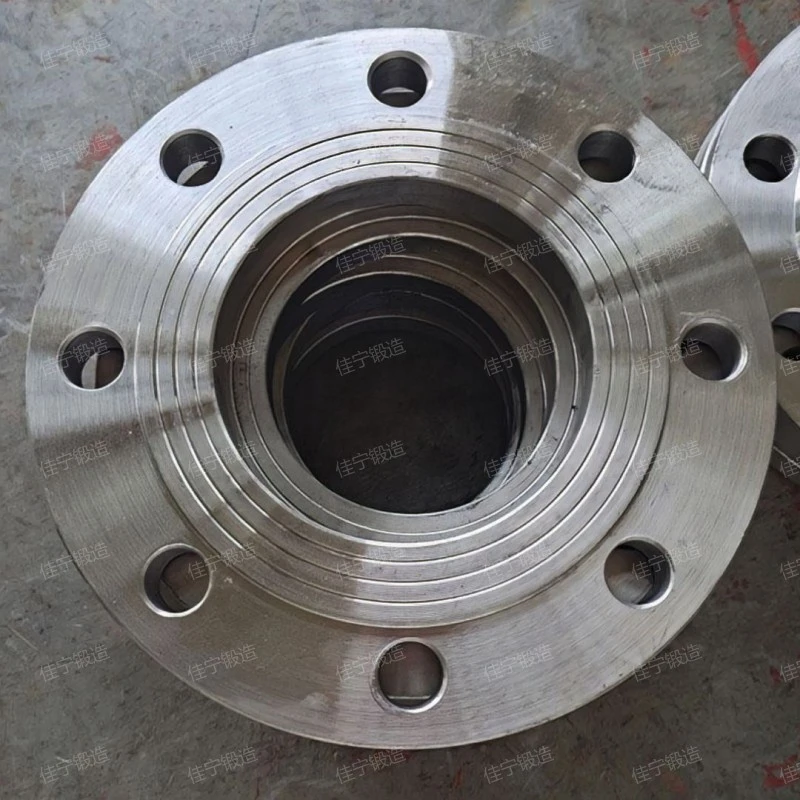

Aluminum ring forged parts

2、Introduction of advantages of Aluminum ring forged parts

The advantages of Aluminum ring forged parts are as follows:

- Optimizing structural design

- Improve material utilization rate

- Good fatigue resistance.

- Good chemical uniformity

- Replace other processing methods

On the premise of ensuring the design strength, through reasonable structural design, the Aluminum ring forged parts can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Aluminum ring forged parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The particle flow inside the Aluminum ring forged parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

Forging can disperse the segregation of alloy or nonmetal and make the Aluminum ring forged parts have excellent chemical uniformity.

In some cases, Aluminum ring forged parts can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Aluminum ring forged parts

3、Aluminum ring forged parts video detail

The following is the live video of Aluminum ring forged parts designed and produced by Jianing forging for users, from which we can see the the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Aluminum ring forged parts.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Aluminum ring forged parts can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal. of JianingAluminum ring forged parts.。

Aluminum ring forged parts

As you can see from the live video.,Jianing refers to the workpiece or blank obtained by forging metal blank.。

4、Aluminum ring forged parts performance advantage

Aluminum ring forged partss have the following advantages.

- High dimensional accuracy

- Meet the requirements of complex working conditions

- Perfect quality assurance system

- High degree of automation

- high tenacity

In the forging process of Aluminum ring forged parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The Aluminum ring forged parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the process of Aluminum ring forged parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Aluminum ring forged parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The fiber structure of the Aluminum ring forged parts is reasonably distributed, which improves the toughness of the material and enables the Aluminum ring forged parts to bear greater impact force and alternating stress.

Aluminum ring forged parts

5、How much is the Aluminum ring forged parts?

The Aluminum ring forged parts price is introduced as follows:

- Company size

- Brand strength

- Reasonable sales model

- Overall configuration

- product costs

The nature of the manufacturer can also greatly affect the price of the Aluminum ring forged parts. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

At present, there are various brands of Aluminum ring forged parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Aluminum ring forged parts are different.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Aluminum ring forged parts are closely related. Jianing forging has comprehensively measured the configuration and sales price of products when designing Aluminum ring forged parts, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. Jianing has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Aluminum ring forged parts

6、Jianing delivery site

Speak directly with facts on the spot。

Aluminum ring forged parts

As you can see from the live video.Jianing forging the product looks atmospheric.。

Aluminum ring forged partsit is widely used inmanufacturing industry,pressure vessel,power,rail traffic,war industry and other industries,it has the characteristics of high tenacity, High production efficiency, Good mechanical properties, Good anti-fatigue performance and Great forging flexibility,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Aluminum ring forged parts.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

Related recommendation

-

Introduction to Double threaded flange, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Pressure vessel tube plate, advantages, characteristics and principles of tube sheet

2025-5-26 -

Introduction to Cylinder forgings and forging advantages and features

2025-5-26 -

What is a Forged parts for pressure vessel end caps? How much is the price of the forging?

2025-5-26 -

45轴锻件

2024-12-10 -

What is a PN260 flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Gate valve forged parts, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Card sleeve internal thread flange cover, how much is the price of the flange?

2025-5-26 -

What is a Concave convex panel flat welding flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Substation flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26