What is a Grade III pressure vessel forgings? Introduction to the advantages and characteristics of the forging

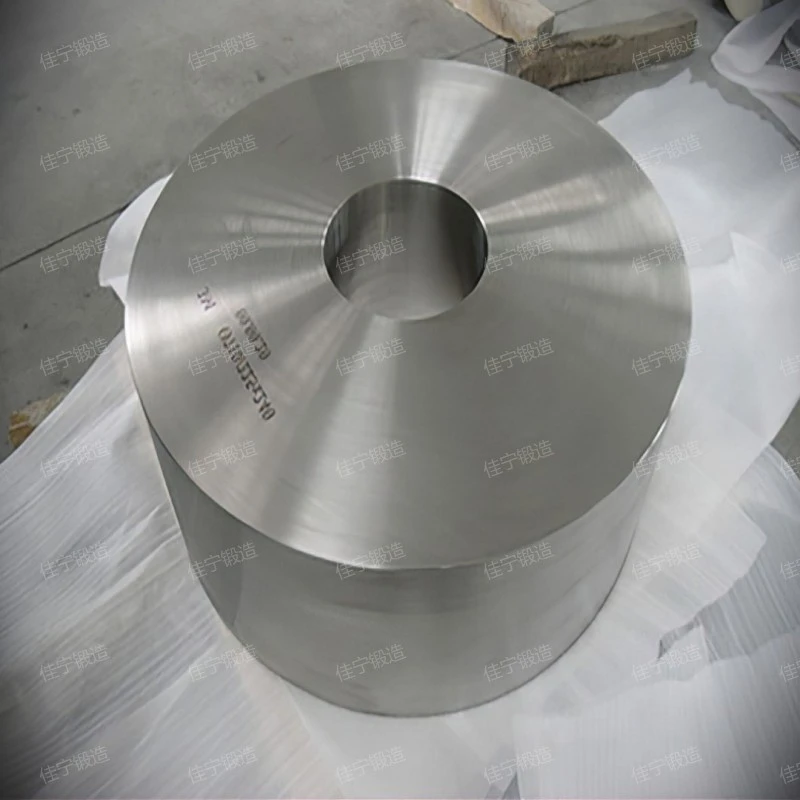

Grade III pressure vessel forgingsrefers to the workpiece or blank obtained by forging metal blank.,the product looks atmospheric.,is a popular Grade III pressure vessel forgings,is a kind of Grade III pressure vessel forgings manufactured by Jianing。The following is to introduce the Grade III pressure vessel forgings:

1、Brief introduction of Grade III pressure vessel forgings

Grade III pressure vessel forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,modern technology。

Grade III pressure vessel forgings

2、Introduction of advantages of Grade III pressure vessel forgings

Grade III pressure vessel forgingss have the following advantages.

- Meet the requirements of complex working conditions

- Eliminate internal defects

- Reduce the amount of subsequent processing

- Good fatigue resistance.

- Replace other processing methods

The Grade III pressure vessel forgings has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Grade III pressure vessel forgings.

The forming precision of the Grade III pressure vessel forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

The particle flow inside the Grade III pressure vessel forgings flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In some cases, Grade III pressure vessel forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Grade III pressure vessel forgings

3、Grade III pressure vessel forgings characteristics

Grade III pressure vessel forgingsGood anti-fatigue performance,High productivity,high tenacity,Light weight,high-intensity,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Grade III pressure vessel forgings can be improved.,the product looks beautiful.,is developed and improved by Jianing forging。

Grade III pressure vessel forgings

4、Grade III pressure vessel forgings explanation video

You can buy Grade III pressure vessel forgings according to your needs and show you product videos.。

Grade III pressure vessel forgings

As you can see from the live video.,Shanxi jianing forging co., ltd it is widely used in war industry, rail traffic, power, automobile and war industry。

5、How much is the Grade III pressure vessel forgings?

The Grade III pressure vessel forgings price is introduced as follows:

- cost of production

- service

- market

- Low cost of raw materials

- model

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Grade III pressure vessel forgings.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Grade III pressure vessel forgings price and service can meet the actual needs of customers.

Market change is the main factor that affects the price level. Because of the instability and uncertainty of the market, the sales price of Grade III pressure vessel forgings will fluctuate greatly, and the market changes are various.

The cost of manufacturing Grade III pressure vessel forgings varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

The same type of equipment, with different models and sizes, has different investment costs, so the quotations to customers are naturally different. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

Grade III pressure vessel forgings

6、Introduction of Jianing Company

Jianing forging, as one of the professional and powerful Grade III pressure vessel forgings manufacturers in Xinzhou, produces Grade III pressure vessel forgings with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

Jianing

Grade III pressure vessel forgingsfeatures include High production efficiency, high-intensity, Great forging flexibility, High productivity and Good mechanical properties,the product looks beautiful.,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

Related recommendation

-

What is a Aluminum alloy wheel? Introduction to the advantages and characteristics of wheel functions

2025-5-26 -

What is a Orifice gear? gear specifications, models, and parameters

2025-5-26 -

What is a RF gear? How much is the price of the gear?

2025-5-26 -

What is a Concave convex sealing face welding flange cover? How much is the price of the flange?

2025-5-26 -

What is a Flat gear? How much is the price of the gear?

2025-5-26 -

What is a Ring groove sealing face welding flange ring? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Internal thread flange and flange structure principle

2025-5-26 -

What is a Drive shaft free forging? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to Rod forging and forging structure principle

2025-5-26 -

What is a Low neck butt welded flange? Introduction to the principle of flange structure

2025-5-26