What is a Manhole free forging? forging specifications, models, and parameters

Manhole free forgingis a workpiece or blank obtained by forging and deforming a metal blank.。The following is to introduce the Manhole free forging:

1、Brief introduction of Manhole free forging

Manhole free forgingthe forging machine is used to exert pressure on the blank.,support customization。

Manhole free forging

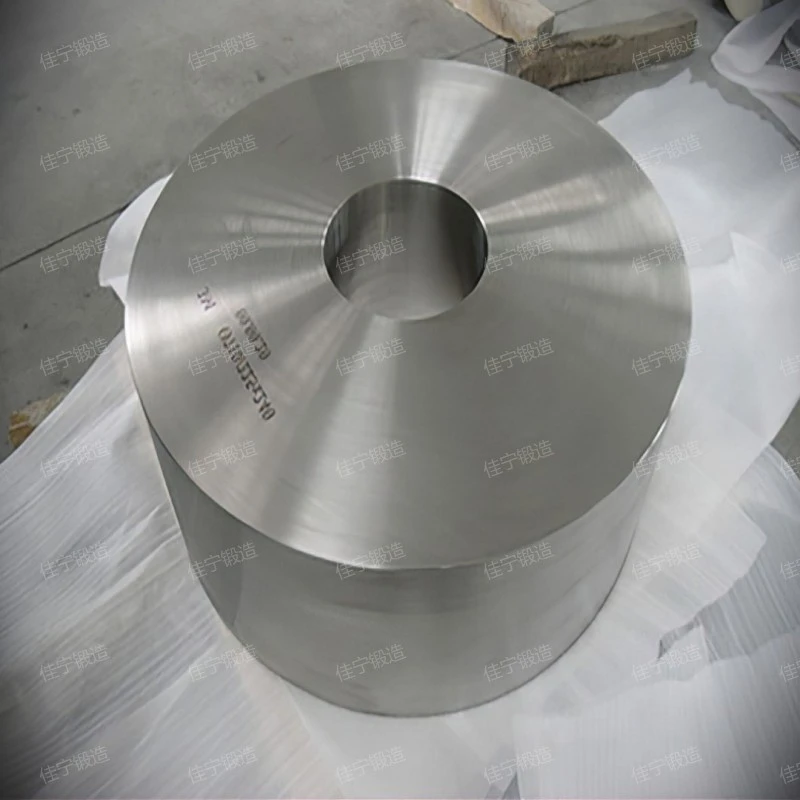

2、Manhole free forging display

Manhole free forging high-definition picture display, all-round shooting without dead ends, for our customers to visit.。

Manhole free forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Introduction of Manhole free forging characteristics

Manhole free forgingfeatures include high-precision, Can bear large impact force or heavy load., Light weight, Good mechanical properties and High productivity,usually used in metallurgy, automobile, construction machinery, war industry, manufacturing industry and other fields,is a Manhole free forging,refers to the workpiece or blank obtained by forging metal blank.,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

Manhole free forging

4、Manhole free forging characteristics

Manhole free forginghigh-intensity,Save raw materials,Good anti-fatigue performance,High production efficiency,Can bear large impact force or heavy load.,the product looks atmospheric.,is a popular Manhole free forging。

Manhole free forging

5、Manhole free forging advantage

The advantages of Manhole free forging are as follows:

- Good chemical uniformity

- Improve material utilization rate

- Good fatigue resistance.

- Replace other processing methods

- Eliminate internal defects

Forging can disperse the segregation of alloy or nonmetal and make the Manhole free forging have excellent chemical uniformity.

In the process of Manhole free forging production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

The particle flow inside the Manhole free forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In some cases, Manhole free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Manhole free forging.

Manhole free forging

6、Jianing forging workshop picture real shot

The finished products of the Manhole free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Manhole free forging factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Manhole free forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the main features are high tenacity, High productivity, Save raw materials, Great forging flexibility and high-intensity,the product looks beautiful.。

Related recommendation

-

What is a Convex neck flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a ABS gear? How much is the price of the gear?

2025-5-26 -

Introduction to Q345 alloy forgings and forging advantages and features

2025-5-26 -

Introduction to Shaft seat forging and forging working principle

2025-5-26 -

What is a SAE welded flange cover? Introduction to the principle of flange structure

2025-5-26 -

What is a Q235 pressure vessel butt welding flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Joint groove facing welded flange ring and flange structure principle

2025-5-26 -

Introduction to Chemical Department Plate Flat Welding Flange Ring, how much is the price of the flange?

2025-5-26 -

核电合金钢锻件

2024-12-10 -

Introduction to Stainless steel valve forging parts, forging specifications, model parameters

2025-5-26