Introduction to Stainless steel valve forging parts, forging specifications, model parameters

Stainless steel valve forging partsrefers to the workpiece or blank obtained by forging metal blank.,the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Stainless steel valve forging parts can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。The following is to introduce the Stainless steel valve forging parts:

1、Brief introduction of Stainless steel valve forging parts

Stainless steel valve forging partsthe forging machine is used to exert pressure on the blank.。

Stainless steel valve forging parts

2、Stainless steel valve forging parts advantage

The advantages of Stainless steel valve forging parts are as follows:

- Perfect quality assurance system

- Reduce the amount of subsequent processing

- High degree of automation

- Meet the requirements of complex working conditions

- high tenacity

In the process of Stainless steel valve forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Stainless steel valve forging parts.

The forming precision of the Stainless steel valve forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The Stainless steel valve forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The fiber structure of the Stainless steel valve forging parts is reasonably distributed, which improves the toughness of the material and enables the Stainless steel valve forging parts to bear greater impact force and alternating stress.

Stainless steel valve forging parts

3、Introduction of Stainless steel valve forging parts characteristics

Stainless steel valve forging partsthe main features are High productivity, Can bear large impact force or heavy load., Good mechanical properties, Light weight and high tenacity,is a Stainless steel valve forging parts newly developed by Jianing forging。

Stainless steel valve forging parts

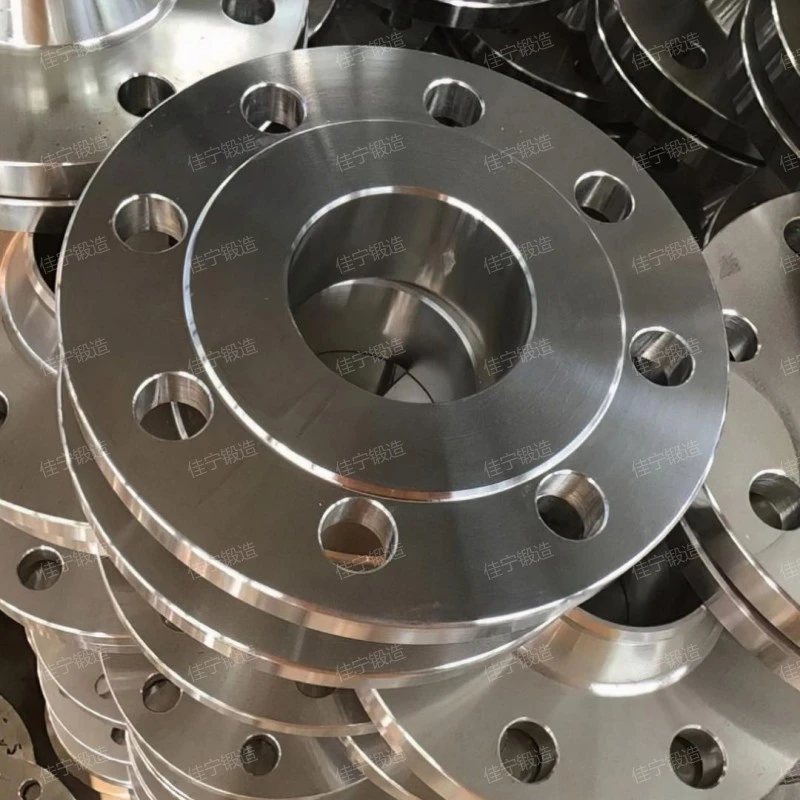

4、Stainless steel valve forging parts HD picture real shot

Stainless steel valve forging parts specifications and models, novel design, beautiful appearance, for our customers to visit.。

Stainless steel valve forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、How much is the Stainless steel valve forging parts?

The Stainless steel valve forging parts price is introduced as follows:

- After-sales service level

- technology

- Cost input

- product configuration

- specifications and models

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing Stainless steel valve forging parts manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Stainless steel valve forging parts price can meet the purchasing needs of customers.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

Jianing forging has a large production scale, strong manufacturing strength and high degree of automation in product production. In such a manufacturing environment, the cost of manufacturing Stainless steel valve forging parts in Jianing is greatly reduced.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Stainless steel valve forging parts, which is beyond doubt. Jianing forging makes every product with great care in the attitude of being highly responsible to customers, so the price of Jianing Stainless steel valve forging parts is reasonable for products with the same configuration.

Different customers need different output, different specifications, different product configurations, and their Stainless steel valve forging parts prices are also different. The bigger the specification, the stronger the performance of the product and the higher the quotation.

Stainless steel valve forging parts

6、How to choose the right product manufacturer?

Choosing a suitable Stainless steel valve forging parts manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Stainless steel valve forging parts products that meet the demand and have good cost performance.。

Jianing forging

Stainless steel valve forging partsit has been widely used in manufacturing industry, construction machinery, shipping, automobile, manufacturing industry and other industries,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Stainless steel valve forging parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,is a common Stainless steel valve forging parts。

Related recommendation

-

What is a Protruding threaded flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a Variable diameter convex surface flat welding flange ring? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Boiler suspension rod forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a Threaded flange cover? How much is the price of the flange?

2025-5-26 -

Introduction to Rotary gear forgings and gear structure principle

2025-5-26 -

Introduction to Low temperature steel cylinder forging parts, forging specifications, model parameters

2025-5-26 -

Introduction to Q355C alloy free forging and forging working principle

2025-5-26 -

Introduction to Double phase steel flat welding flange, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Domestic forged parts and forging structure principle

2025-5-26 -

Introduction to Flat welding flanges for steam pipelines, introduction to flange advantages and characteristics

2025-5-26